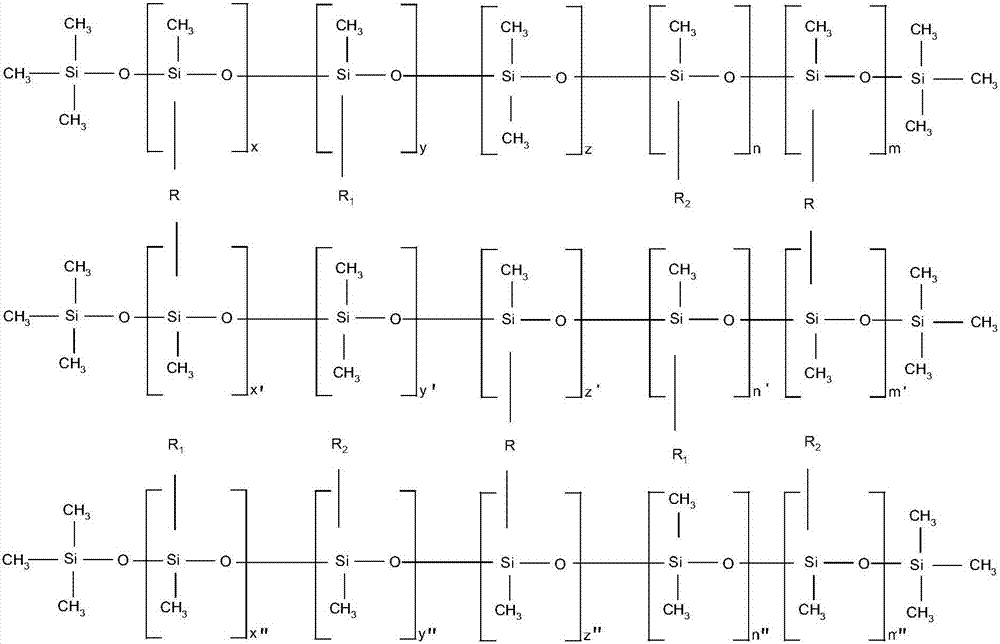

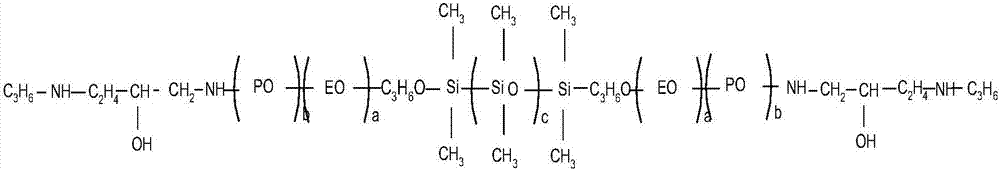

Preparation method of amino modified silicone oil finishing agent with net-shaped structure

A kind of amino-modified silicone oil, network structure technology, applied in soft and smooth treatment. , In the field of preparation of amino-modified silicone oil finishing agent with network structure, it can solve the problems of poor hand feeling, inability to achieve softness, smoothness and rebound, and decreased fabric softness, and achieve low cost of raw materials, good self-emulsification effect and outstanding hand feeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]In the first step, the hydrogen-containing silicone oil with a hydrogen content of 0.03%, a kinematic viscosity of 150 mPa·s, a molecular weight of 300 allyl polyoxyethylene polyoxypropylene epoxy ether, a molecular weight of 300 allyl polyoxyethylene alcohol ether, and three They were mixed in proportion (molar ratio) 4:3:1 and added to the reaction kettle, stirred and heated up, heated to 83°C, and an ethanol solution with a concentration of 4% chloroplatinic acid accounting for 0.04% of the total mass of the material was added, and reacted for 3 hours to obtain The color transparent product is the intermediate of epoxy-terminated polyether modified silicone oil.

[0041] In the second step, the ratio (mass ratio) of octamethylcyclotetrasiloxane to the composite silane coupling agent is 200:7, wherein N-(γ,-dimethylaminopropyl)- γ-Aminopropylmethyldimethoxysilane: N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane is added to the reactor in a ratio (molar ratio) of 1:...

Embodiment 2

[0044] In the first step, hydrogen-containing silicone oil with a hydrogen content of 0.05% and a kinematic viscosity of 90 mPa·s: a molecular weight of 500 allyl polyoxyethylene polyoxypropylene epoxy ether: a molecular weight of 500 allyl polyoxyethylene alcohol ether in proportion (Molar ratio) 9:7:2 mixed into the reaction kettle, stirred and heated up, heated to 84°C, added an ethanol solution with a concentration of 4% chloroplatinic acid accounting for 0.03% of the total mass of the material, and reacted for 4 hours to obtain a colorless and transparent product , which is the intermediate of epoxy-terminated polyether modified silicone oil.

[0045] In the second step, the ratio (mass ratio) of octamethylcyclotetrasiloxane to the composite silane coupling agent is 200:13, wherein N-(γ,-dimethylaminopropyl)- γ-Aminopropylmethyldimethoxysilane: N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane is added to the reactor in a ratio (molar ratio) of 1:1.15 and stirred to rai...

Embodiment 3

[0048] In the first step, hydrogen-containing silicone oil with a hydrogen content of 0.08% and a kinematic viscosity of 50 mPa·s: a molecular weight of 1,000 allyl polyoxyethylene polyoxypropylene epoxy ether: a molecular weight of 1,000 allyl polyoxyethylene alcohol ether in proportion (Molar ratio) 5:4:1 mixed into the reaction kettle, stirred and heated up, heated to 85°C, added an ethanol solution with a concentration of 4% chloroplatinic acid accounting for 0.03% of the total mass of the material, and reacted for 2 hours to obtain a colorless and transparent product , which is the intermediate of epoxy-terminated polyether modified silicone oil.

[0049] In the second step, the proportion (mass ratio) of octamethylcyclotetrasiloxane: composite silane coupling agent is 10:1, wherein N-(γ,-dimethylaminopropyl)- γ-Aminopropylmethyldimethoxysilane: N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane is added to the reactor in a ratio (molar ratio) of 1:1.2 and stirred to rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com