Concrete agitating device

A mixing device and concrete technology, which are applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of concrete corrosion of the inner wall of the mixer, uneven mixing, low mixing efficiency, etc., and achieve buffering of concrete impact and corrosion resistance. ability, reducing noise pollution, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

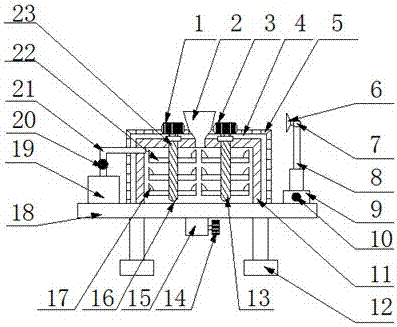

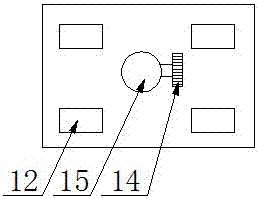

[0017] Such as Figure 1-2 As shown, the present invention provides a concrete mixing device, comprising a base 9, a bracket 18 and a water tank 19, the surface of the base 9 is embedded with a switch 10, the top of the base 9 is fixedly equipped with a telescopic rod 8, the base 9 The bottom end is fixedly provided with a support 18, and one side of the bottom end of the support 18 is welded with a support seat 12, and the bottom end of the support 18 is provided with a discharge port 15, and one side of the discharge port 15 is screwed with a control knob 14, and the support 18 The top is provided with a stirring device main body 4, and the inside of the stirring device main body 4 is provided with a stirring chamber 16. The top of the stirring device main body 4 is clamped with a feed port 2, and one side of the feed port 2 is provided with a first motor 1, and the feed The other side of the mouth 2 is equipped with a second motor 3, and a water tank 19 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com