Cylindrical workpiece drilling device

The technology of a columnar workpiece and a drilling device is applied in the field of mechanical processing, which can solve the problems of difficult processing, large clamping difficulty, low production efficiency, etc., and achieve the effects of improving drilling stability, facilitating drilling processing, and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

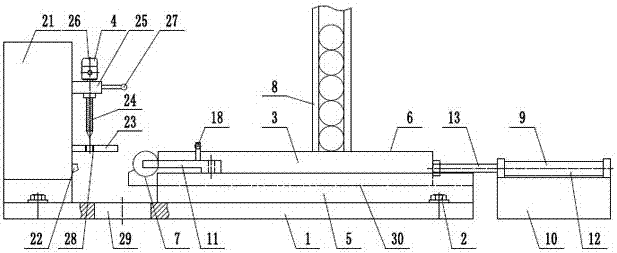

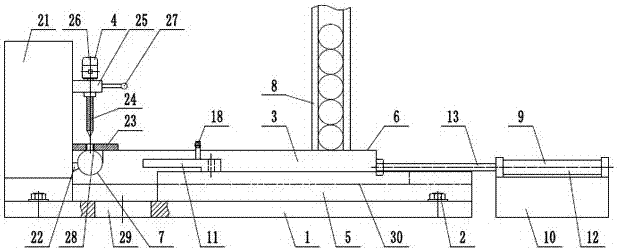

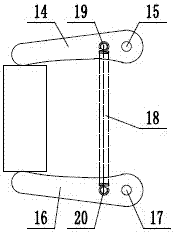

[0015] like figure 1 , figure 2 and image 3 Shown, a kind of drilling device of columnar workpiece, it comprises frame 1, fastening screw 2, loading and unloading mechanism 3, drilling mechanism 4, and described fastening screw 2 is installed on the frame 1, and described loading and unloading The mechanism 3 includes a guide seat 5, a feeding slide plate 6, a material receiving groove 7, a material channel 8, a loading and unloading cylinder 9, a cylinder support 10, and a blanking assembly 11. The guide seat 5 is fixed on the right end of the frame 1. The above-mentioned feeding slide plate 6 can be slidably arranged on the guide seat 5 left and right, and the guide seat 5 is provided with a dovetail-shaped gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com