Integral-injection-molded brush disc

A technology of injection molding and brush trays, which is applied in the direction of brushes, bristle brackets, household appliances, etc., can solve the problems of reducing the service life of brushes, cumbersome brush tray production process, and affecting product quality, so as to improve production efficiency and product specifications. Good uniformity, convenient and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

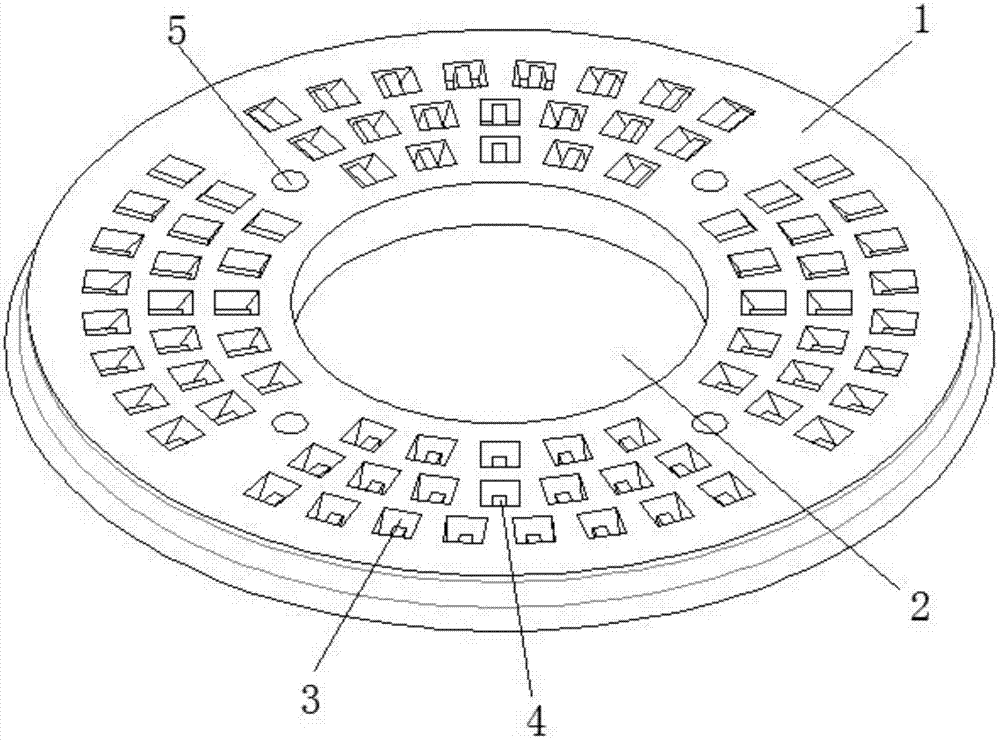

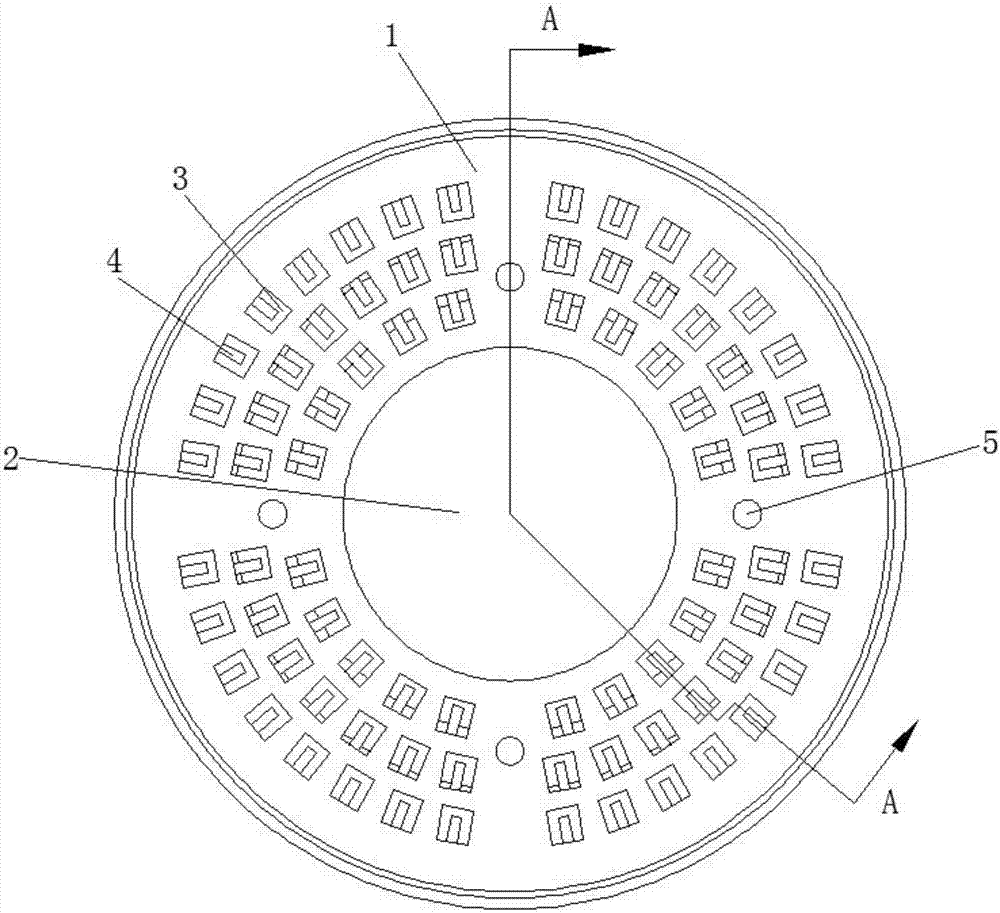

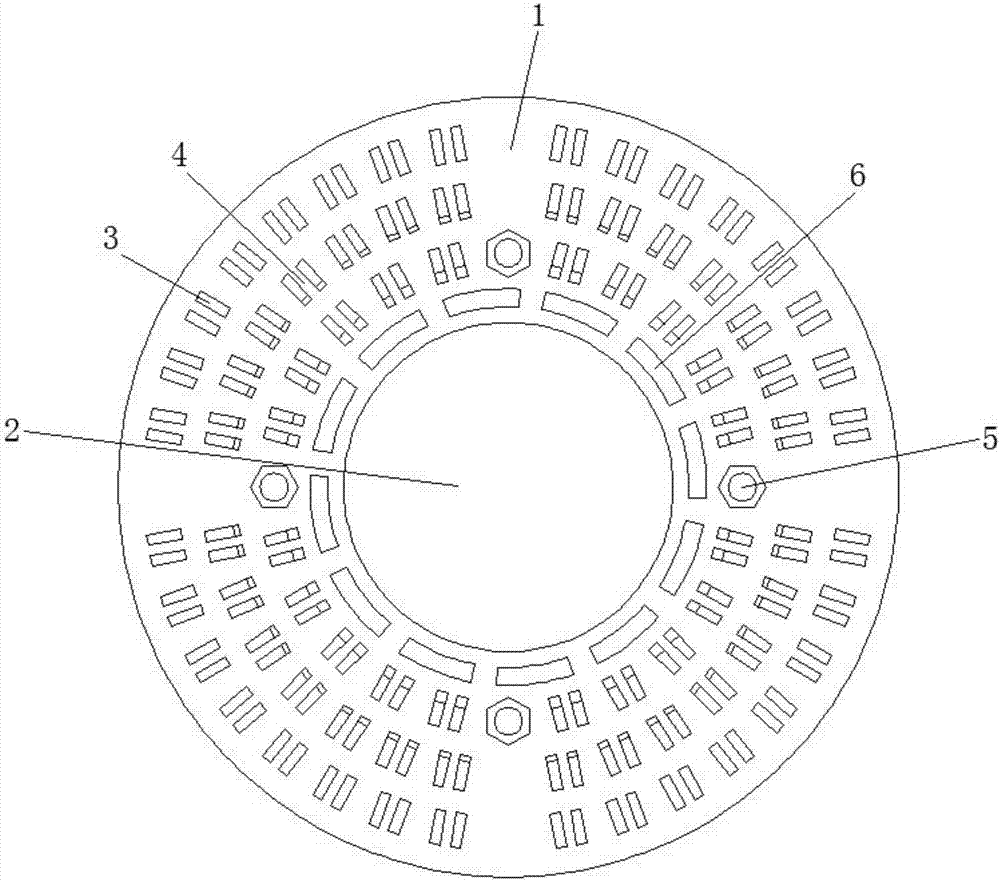

[0018] Referring to the accompanying drawings, an integral injection molded brush tray includes a brush tray body 1, which is a cylindrical disc structure that is integrally injection-molded. The brush tray body 1 is made of polyethylene or polyvinyl chloride material by injection molding. The brush tray The center of the body 1 is provided with a through hole 2, and the end surface of the brush body 1 is provided with multiple rows of annularly arranged socket groups. Evenly distributed in the radial direction, each row of jacks includes a plurality of square jacks 3 evenly distributed around the axis of the brush body 1, the jacks 3 are inclined from top to bottom in the vertical plane, and each row of jacks 3 The angle of inclination decreases from the inside to the outside in turn, the middle part of the jack 3 is provided with a partition 4, the jack group is divided into four sections distributed at equal intervals, and a connecting hole 5 is provided at the interval betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com