Method for preparing Mn3o4 hollow micronano cubic block by employing metal-organic framework (MOF) template

A hollow micro-cube technology, which is applied in the manufacture of hybrid/electric double layer capacitors and hybrid capacitor electrodes, can solve the problems of unfavorable large-scale application, complex preparation process and high cost of hollow structure metal oxides, and achieve cheap reaction raw materials , easy to remove, template synthesis simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

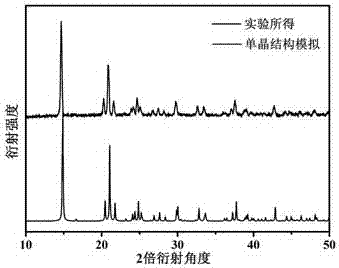

[0015] Synthetic MOF templates

[0016] Accurately weigh 0.1979 g of manganese chloride and 0.5 g of PVP-K30 and dissolve in 25 mL of ethanol and stir to obtain a metal salt solution, dissolve 0.2301 g of anhydrous formic acid and 0.5171 g of methylamine in alcohol solution and stir in 25 mL of ethanol to obtain a ligand solution. The metal salt solution was dropped into the ligand solution and stirred for 2 h. The final product was collected after centrifugation, washing and drying.

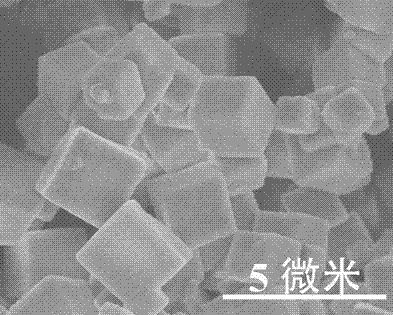

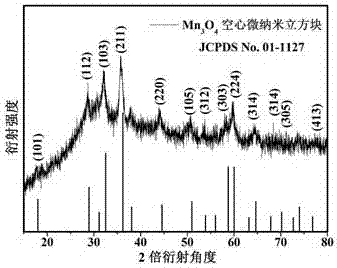

[0017] Synthetic Mn 3 o 4 Hollow micro-nano cubes

[0018] 0.2212 g of MOF template was accurately weighed and dispersed in 50 mL of ethanol with stirring, and then 0.004 g of NaOH was dissolved in 20 mL of ethanol. Drop the alkali solution into the MOF template dispersion liquid, under hydrothermal condition 120 o C reacted for 6 h. After the reactor was cooled to room temperature, the final product was collected after centrifugation, washing and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com