Insulation method of plasma range hood

A range hood and plasma technology, applied in the direction of removing oil fume, heating method, household heating, etc., can solve the problems of greatly reduced effect, loss of dust adsorption, poor oil fume removal effect, etc., to improve the function, prolong the service life, and have a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

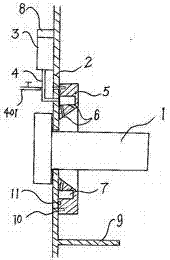

[0019] exist figure 1 Among them, the metal plate on one side of the porcelain joint 1 is installed on the housing, and an insulating plate 2 is used instead, the porcelain joint 1 is fixed on the insulating plate 2, and the air pump 3 of the air jet unit is installed on the housing. Air is supplied to the air injection disc 5 through the main pipeline 4; the main pipeline 4 of the air injection unit is connected to the air pump 3 or directly connected to the external air source pipeline 401 for delivering pressure gas, and the air injection disc 5 of the air injection unit is installed on the ceramic joint The periphery of 1 is used to set multi-directional alignment with the air injection port 6 of the porcelain joint 1;

[0020] The air injection disc of the air injection unit has an internal annular air channel 7 for containing the pressure gas supplied by the air pump; the timing device 8 is installed outside the casing for controlling the injection time period. The gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com