Wheeled loader capable of being configured with travelling working machine tool

A technology of wheel loaders and tools, which is applied to earth movers/excavators, construction, etc., which can solve the problems of reducing the speed ratio coefficient of loaders, slow cleaning speed, and unclean cleaning, etc., to achieve expanded working conditions Adaptable range, simple and convenient operation, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

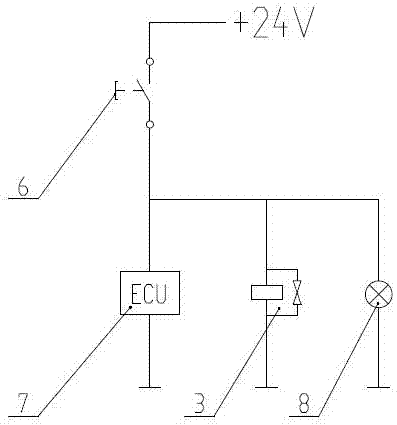

[0024] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

[0025] A wheel loader that can be configured with walking work tools, including a power transmission system and a hydraulic system; the power transmission system includes an engine, a hydraulic torque converter, a gearbox, and an axle; the hydraulic system includes a hydraulic oil tank 1, a hydraulic pump, and a hydraulic valve and hydraulic cylinders. Part of the energy output by the engine is transmitted to the traveling mechanism through the hydraulic torque converter and gearbox to drive the entire loader; the other part is used to drive the hydraulic cylinder through the hydraulic torque converter and hydraulic pump to realize steering and operation. ; The above are all prior art, and are not described in detail now.

[0026] combine figure 1 As shown, the hydraulic pump is a double pump 2, which inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com