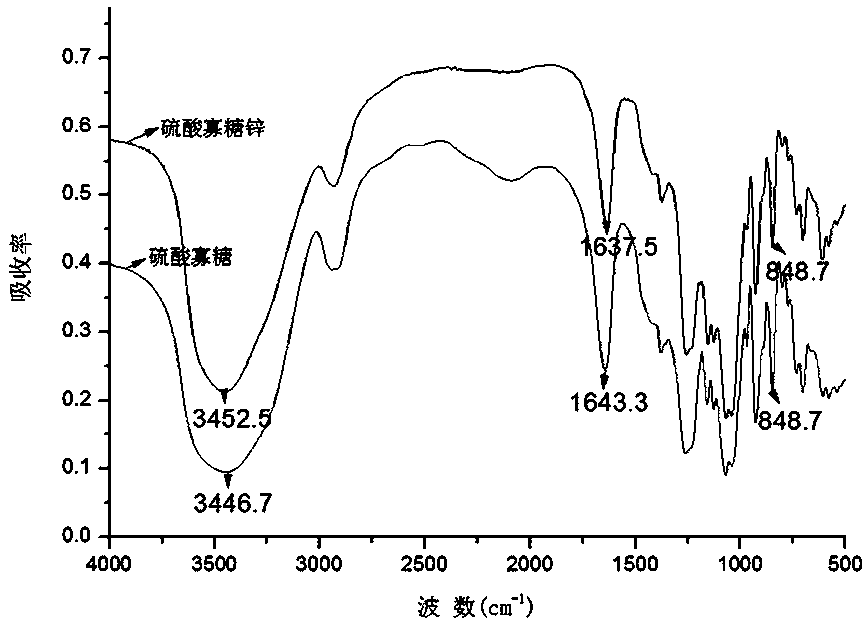

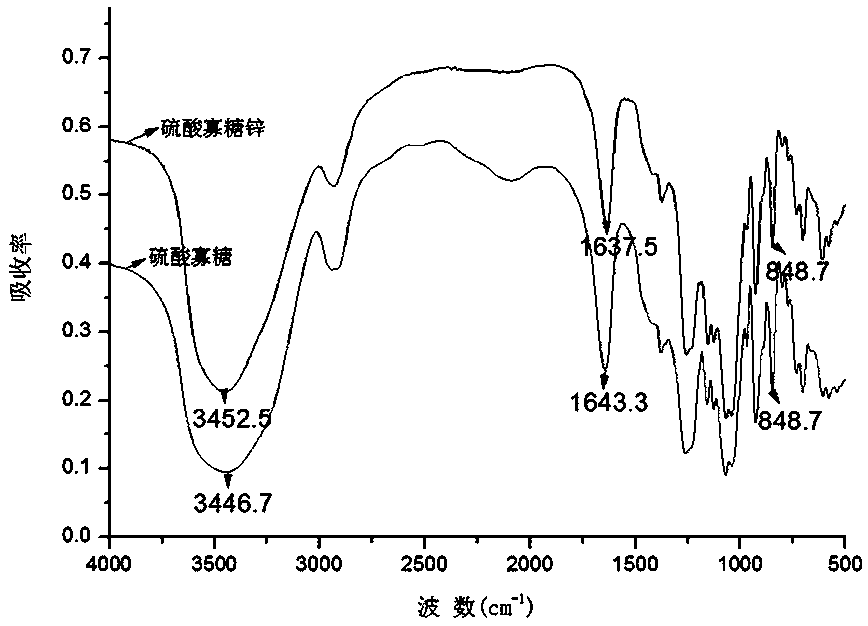

A kind of zinc sulfate oligosaccharide and preparation method thereof

A sulfuric acid polysaccharide and sulfuric acid technology, which is applied in the field of food processing, can solve the problems of high content of functional components zinc and sulfuric acid groups, single product function, low zinc utilization rate, etc., and achieve good fluidity and solubility, high content of sulfuric acid groups, The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A kind of preparation method of oligosaccharide zinc sulfate, concrete steps are:

[0023] (1) Alkali treatment: use NaOH solution with a mass concentration of 10%~30% at 10°C~40°C and 18~30 times the mass of Eucheuma to soak the dried Eucheuma for 10min~30min, filter out the lye, and soak in clean water Algae, change the water every 0.5h until the pH of the algae is 7~8, drain the water;

[0024] (2) Extraction of sulfated polysaccharides: put the algae treated with alkali into water 30 times its mass, heat at 80°C~98°C for 2h~4h, filter the algae residue with 200-mesh silk cloth while it is hot, and cool the filtrate to 25°C After ~50°C, mix three times the volume of the filtrate with 95% ethanol, and then filter with 400-mesh silk cloth to obtain a sulfated polysaccharide solution;

[0025] (3) Preparation of sulfated polysaccharide powder: Concentrate the sulfated polysaccharide solution to a soluble solid content of 20%~55%, and then dry it with a centrifugal spra...

Embodiment 1

[0033] (1) Alkali treatment: Soak the dried Eucheuma in 10% NaOH solution at 40°C and 18 times the mass of Eucheuma for 30 minutes, filter out the alkali solution, soak the algae in clean water, and change the water every 0.5 hours. Drain the water until the pH of the algae is 7;

[0034] (2) Extraction of sulfated polysaccharides: Put the algae treated with alkali into water 30 times its mass, heat at 98°C for 2 hours, filter out the algae residue with 200-mesh silk cloth while it is hot, cool the filtrate to 25°C, and use the filtrate three The volume fraction of twice the volume is 95% alcohol mixing, then filters with 400 order silk cloths to obtain the sulfated polysaccharide solution;

[0035] (3) Preparation of sulfated polysaccharide powder: Concentrate the sulfated polysaccharide solution to a soluble solid content of 20%, and then dry it with a centrifugal spray dryer at an inlet air temperature of 200°C and an outlet air temperature of 90°C until the water content i...

Embodiment 2

[0043] (1) Alkali treatment: Soak dried Eucheuma 25 times the mass of Eucheuma in 20% NaOH solution at 25°C for 20 minutes, filter out the alkali, soak the algae in clean water, and change the water every 0.5 hours. Drain the water until the pH of the algae is 7.5;

[0044] (2) Extraction of sulfated polysaccharides: Put the algae treated with alkali into water 30 times its mass, heat at 90°C for 3 hours, filter out the algae residue with 200-mesh silk cloth while it is hot, cool the filtrate to 40°C, and use the filtrate three The volume fraction of twice the volume is 95% alcohol mixing, then filters with 400 order silk cloths to obtain the sulfated polysaccharide solution;

[0045] (3) Preparation of sulfated polysaccharide powder: Concentrate the sulfated polysaccharide solution to a soluble solid content of 40%, and then dry it with a centrifugal spray dryer at an inlet air temperature of 160°C and an outlet air temperature of 75°C until the moisture content is below 12wt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com