Metal sodium safety treatment method capable of avoiding hydrogen generation

A technology for safe processing and metal sodium, applied in the field of safe processing, can solve the problems of big hidden danger, complicated operation, environmental pollution, etc., and achieve the effects of simple operation, simple equipment, and high safety and controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

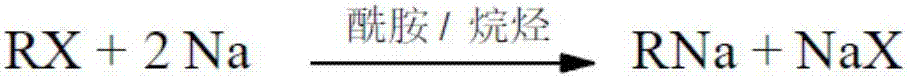

Method used

Image

Examples

Embodiment 1

[0029] A safe treatment method for preventing the generation of hydrogen metal sodium, the specific preparation method is as follows:

[0030] Replace the dry and closed reaction kettle with reflux device with nitrogen for three times, add 46Kg (2kmol) sodium metal and 100Kg toluene into the kettle, turn on steam heating, until the temperature in the kettle rises by 110℃, keep the temperature for 1h, the sodium metal is completely melted , Turn on the stirring, slowly add dropwise a mixture of 253Kg (2kmol) benzyl chloride and 46KgN,N-dimethylformamide, the dripping process is slightly exothermic, the dripping is completed in about 4h, and the temperature is kept at 110℃ for 2h, and the temperature is reduced to 30℃ slowly. 108Kg (6Kmol) of water was added dropwise, and the addition was completed in 2 hours to obtain a saturated aqueous solution of the upper toluene organic phase and the lower layer of sodium hydroxide and sodium chloride.

Embodiment 2

[0032] A safe treatment method for preventing the generation of hydrogen metal sodium, the specific preparation method is as follows:

[0033] Replace the dry and closed reaction kettle with reflux device with nitrogen for three times. Add 23Kg (1kmol) of sodium metal and 50Kg of toluene into the kettle, turn on steam heating until the temperature in the kettle rises by 110℃, keep the temperature for 1h, and the sodium metal is completely melted. , Turn on the stirring, slowly add dropwise a mixture of 171Kg (1kmol) benzyl bromide and 23KgN,N-dimethylformamide, the dripping process is slightly exothermic, and the dripping is completed in about 4h. The temperature is kept at 110℃ for 2h, and the temperature is reduced to 30℃. 54Kg (3Kmol) of water was added dropwise, and the addition was completed in 2 hours to obtain a toluene organic phase and a saturated aqueous solution of sodium hydroxide.

Embodiment 3

[0035] A safe treatment method for preventing the generation of hydrogen metal sodium, the specific preparation method is as follows:

[0036] Replace the dry and airtight reaction kettle with reflux device with nitrogen for three times, add 11.5Kg (0.5kmol) sodium metal and 34Kg toluene into the kettle, turn on the steam heating, until the temperature in the kettle rises by 100℃, keep the temperature for 1h, sodium metal Completely melt, turn on the stirring, slowly add 63Kg (0.5kmol) benzyl chloride and 5KgN,N-dimethylformamide mixture, the dripping process slightly exothermics, about 4h to complete the dripping, 110 ℃ heat preservation 8h, sodium metal The reaction is complete, the temperature is lowered to 30°C, 36Kg (2Kmol) of water is slowly added dropwise, and the dropwise addition is completed in 2h, to obtain a toluene organic phase and a saturated aqueous solution of sodium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com