Aeration device and underground water treatment process

An aeration device and groundwater technology, which is applied in the field of groundwater treatment and groundwater treatment technology, can solve the problems of anions with total hardness exceeding the standard, affect the taste of drinking water, and have a lot of scale in boiled water, etc., and achieve excellent aeration effect and excellent water output effect , the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

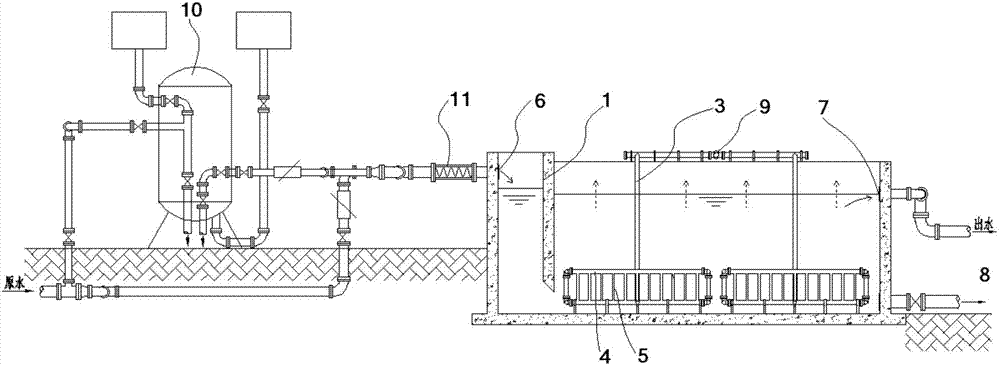

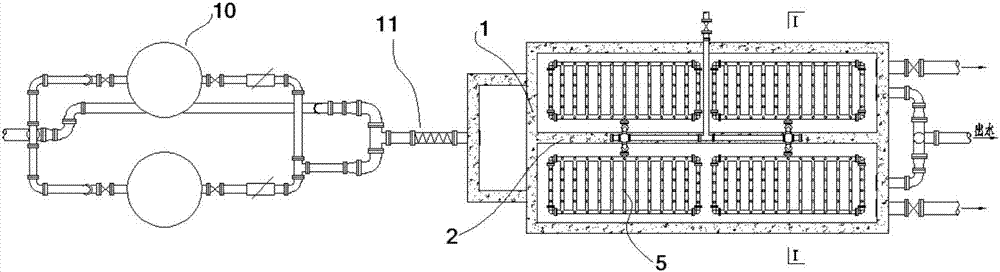

[0034] The depth of the aeration device in this embodiment is 3.5-4.5m, which can be adjusted according to the amount of water to be aerated during specific use.

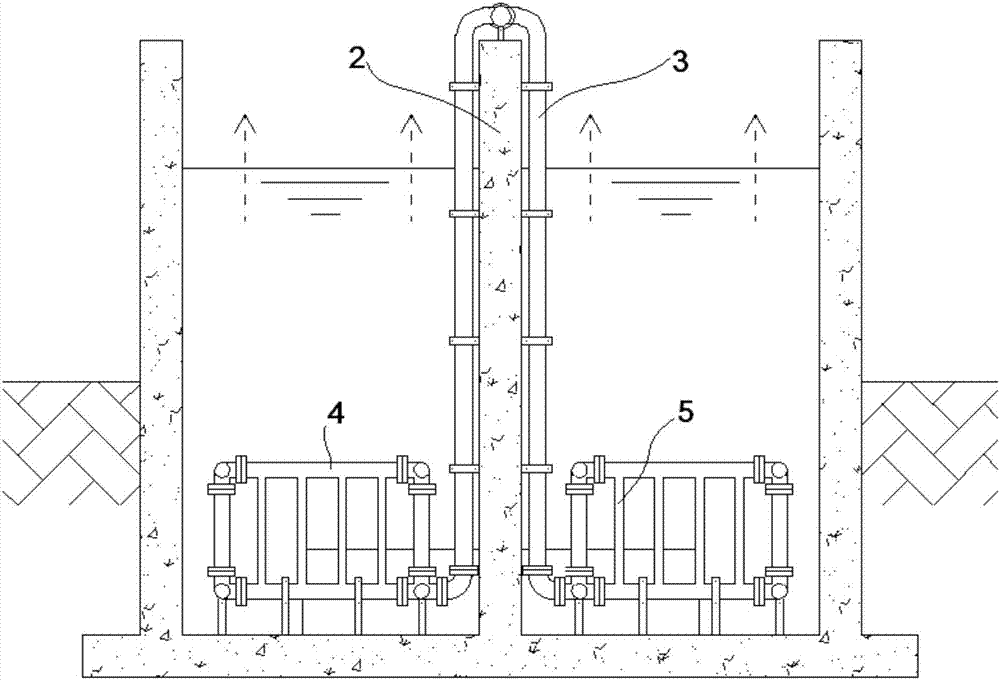

[0035] This embodiment provides an aeration device, in which a first vertical partition 1 and a second vertical partition 2 are arranged, the first vertical partition 1 and the second vertical partition 2 are vertically connected to each other, and the second One vertical partition 1 is not in contact with the bottom of the device for passing water, and the second vertical partition 2 is in contact with the bottom of the device to separate the aeration area. If the second vertical partition 2 is in the first vertical partition 1 On the central axis, it plays the role of evenly distributing the water; the second vertical partition 2 is surrounded by the second vertical partition 2 with a ventilation main pipe 3, and the second vertical partition 2 and the device form The space is provided with a ventilation branch pi...

Embodiment 2

[0041] This embodiment provides a groundwater treatment process. After the groundwater to be treated enters the hydrogen ion exchanger 10, it is mixed with the original groundwater to be treated at a volume ratio of 1:5 through the mixer 11, and then enters the aeration device for aeration.

[0042] The hydraulic retention time of the water to be treated through the water inlet 6 of the aeration device is 3 minutes, and the hydraulic retention time in the space formed by the second vertical partition 2 and the device is 45 minutes. The air-water ratio of the aeration device is B / 10, where B represents the temporary hardness of the groundwater to be treated.

[0043] Present embodiment technological process is:

[0044] After being treated by the ion exchanger, the water to be treated is mixed with the raw water by a static mixer at a volume ratio of 1:5, and after being fully mixed, it enters the water inlet area of the aeration device, and then enters the aeration device fr...

Embodiment 3

[0048] This example takes groundwater somewhere in Xi'an City, Shaanxi Province as an example. The air-to-water ratio of the aeration device is 1:5. The effect of Example 2 is verified, and the total hardness of the reactor effluent is monitored in the laboratory.

[0049] Adopt the method described in the present invention, i.e. "replacement+mixing+aeration", each index is as follows:

[0050]

[0051] After several test runs, it can be seen that when the mixing ratio of treated water and raw water is 1:5, the pH of the effluent is stable and then maintained at about 6.55, the hardness of the aeration is basically unchanged before and after aeration, and the total hardness of the effluent is maintained at about 3 / 4 of the raw water , The effluent water is clear after boiling, without precipitation and floating matter, and solves the problems of pH and water hardness at the same time, which meets the relevant standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com