Pattern preparation method and electronic equipment

A technology of electronic equipment and patterns, which is applied in the direction of electrical equipment casings/cabinets/drawers, electrical components, casings/cabinets/drawer parts, etc., can solve the problems of logo pattern falling off and logo pattern limitations, and achieve The logo pattern is firm, it is convenient for large-scale industrial application, and the process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

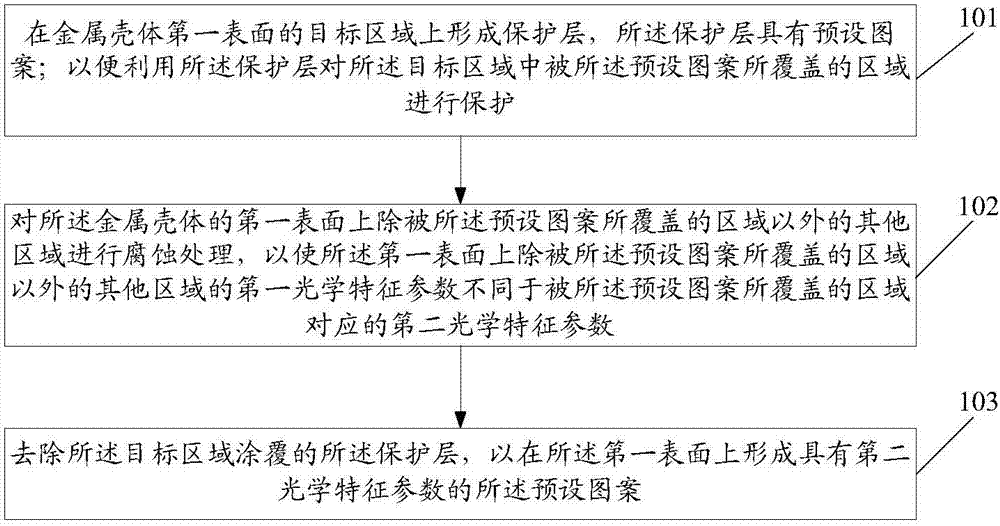

[0027] This embodiment provides a pattern preparation method, specifically, figure 1 It is a schematic flow diagram of the realization of the first pattern preparation method of the embodiment of the present invention, such as figure 1 As shown, the method includes:

[0028] Step 101: Form a protective layer on the target area of the first surface of the metal shell, the protective layer has a preset pattern; so that the area covered by the preset pattern in the target area is protected by the protective layer. Protection, that is to say, using the protective layer to protect the area where the preset pattern needs to be formed.

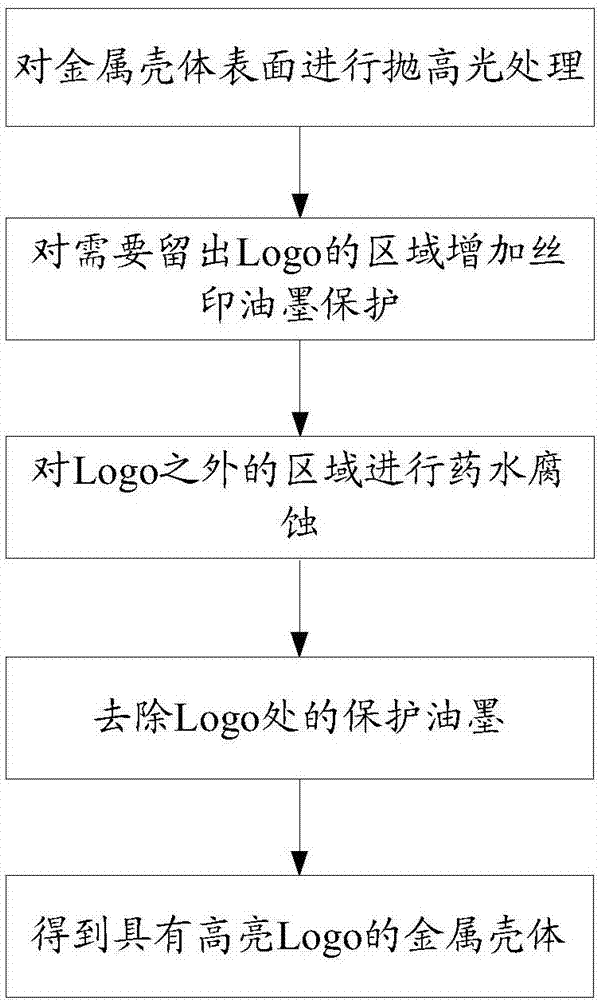

[0029] In this embodiment, the preset pattern may specifically be the pattern of the trademark Logo, that is to say, on the first surface (such as the outer surface) of the metal shell, the area where the pattern of the trademark Logo needs to be set forms a protective layer, so that , in order to use the protective layer to protect the area wher...

Embodiment 2

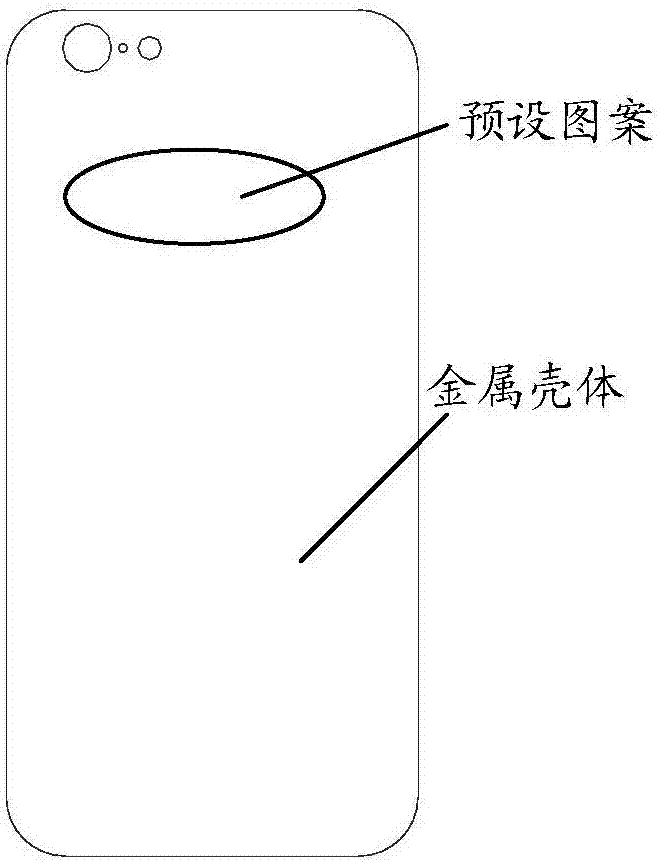

[0039] This embodiment provides an electronic device. The electronic device described in this embodiment may be any device with a metal casing. Further, the electronic device is at least provided with a processor capable of data processing; specifically, the The metal casing includes a pattern forming a trademark Logo, and the pattern is formed on the outer surface of the metal casing; the visual effect of the pattern is different from the visual effect of the area on the metal casing except for the pattern; The metal shell is an integrated metal plate, and the metal plate does not have a hole reserved for the Logo.

[0040] In this embodiment, the metal shell can be prepared using the following process. Specifically, first, a protective layer is formed on the target area of the first surface of the metal shell, and the protective layer has a preset pattern; in order to use The protective layer protects the area covered by the preset pattern in the target area, that is to sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com