Injection mould

An injection mold and movable mold technology, applied in the field of injection molds, can solve the problems of low product yield and reduced production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

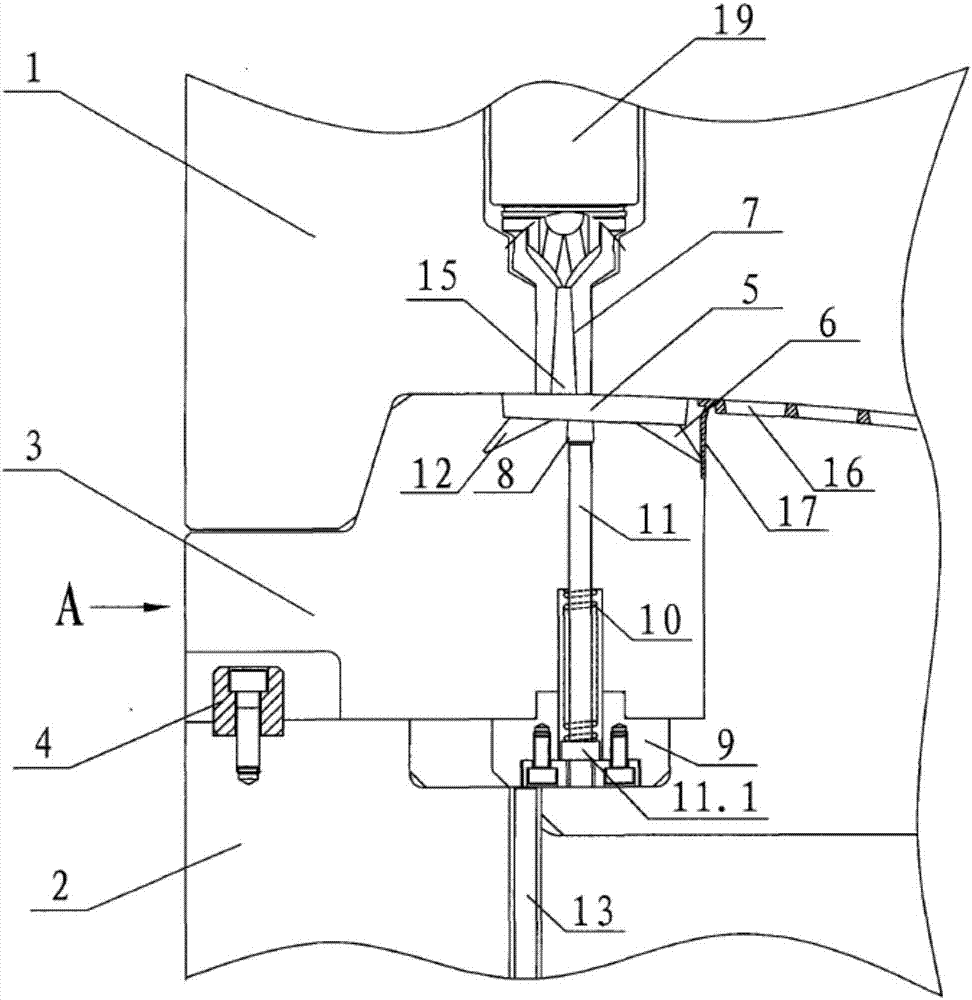

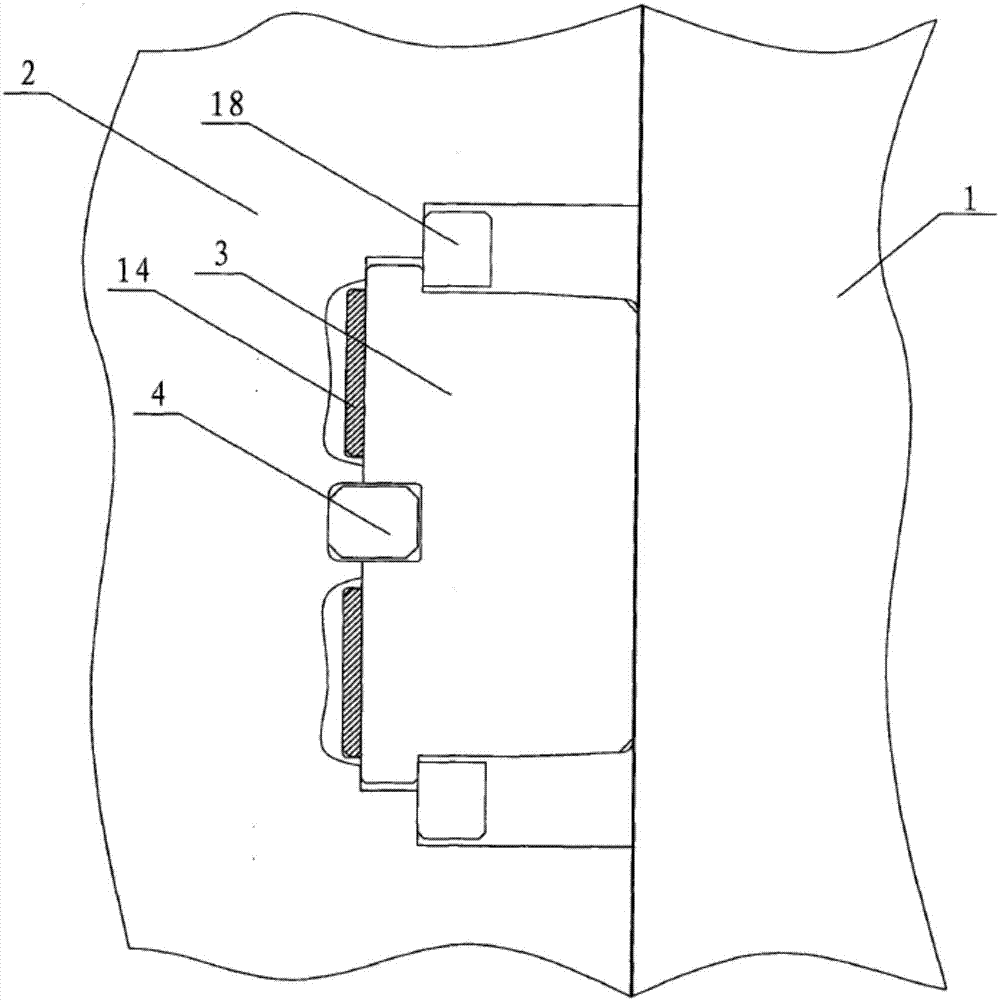

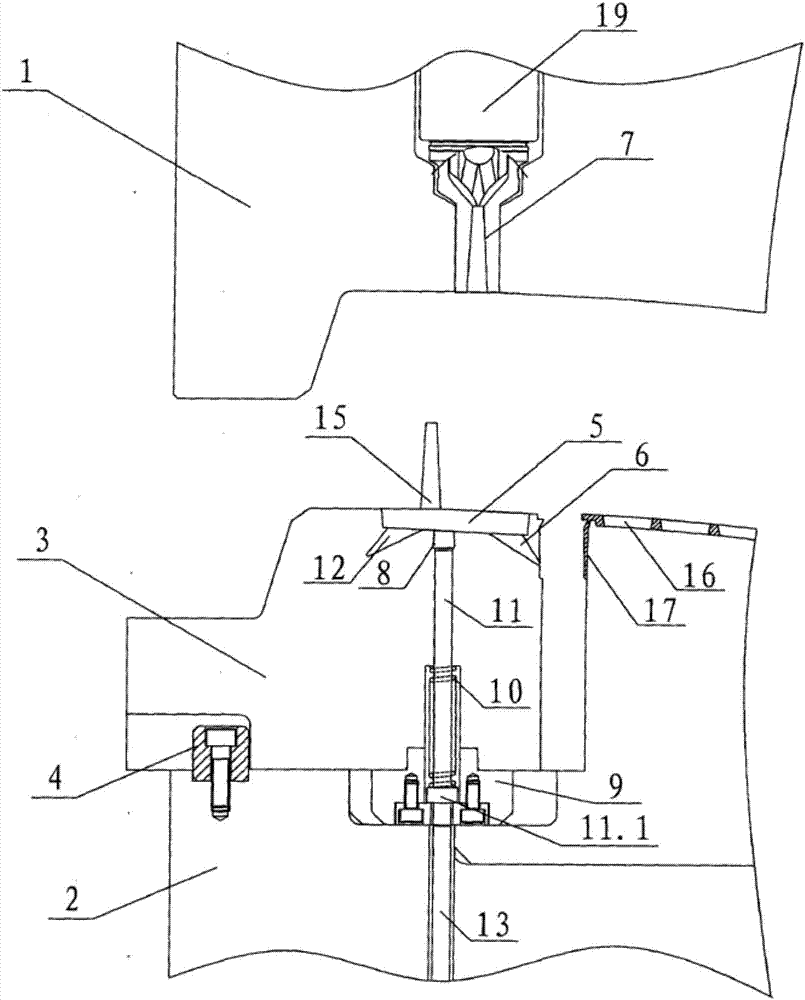

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] The injection mold of the present invention comprises a static mold 1 and a power mold 2, the movable mold 2 is provided with a slider 3 and a limit block 4 for limiting the sliding distance of the slider 3, and the slider 3 is provided with a flow channel 5. Gate I6, the ejector device for item discharge handle 15: the slider 3 is slidably connected with the movable mold 2, the limit block 4 is fixedly connected with the movable mold 2 by bolts; the runner 5 It communicates with the gate I6, and the runner 5 also communicates with the main channel 7 of the static mold 1; the gate I6 communicates with the core wall 17, that is to say, the gate I6 is located at the inner wall of the product; the gate I6 communicates with the inner wall of the product; The ejector device is installed in the slide block 3 , and the item outlet 8 of the ejector device communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com