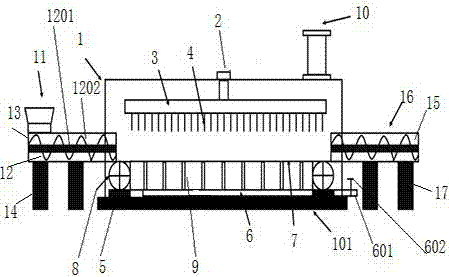

Rubbish heat drying device and method

A waste and drying technology, applied in chemical instruments and methods, drying gas arrangement, drying and other directions, can solve the problems of insufficient utilization of flue gas heat, reduce the moisture content of waste, and rarely use waste, etc. Improve dehydration efficiency, good drying effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

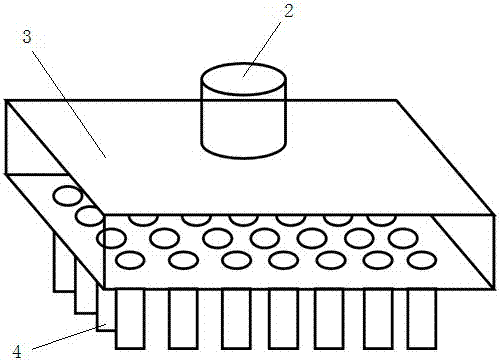

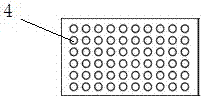

Method used

Image

Examples

Embodiment

[0064] Example: Garbage samples with a moisture content of 50% are continuously fed into the drying box at a rate of 15.3 t / h, and the high-temperature flue gas at 250°C is discharged at a rate of 5140.8 Nm 3 The rate of / h enters the high-temperature flue gas chamber from the air inlet, and is sprayed out by the purge needle according to the setting of the first gear; at the same time, the conveyor belt transports the garbage material forward at a running speed of 2.78 mm / s (the garbage is drying The residence time in the box is 1 h). During this process, after the heat exchange between the high-temperature flue gas and the garbage materials, the waste flue gas formed enters the flue gas treatment device from the exhaust port for purification and discharge. At this time, the waste flue gas The air temperature is 20°C, and the dried garbage is pushed out by the screw discharge device and discharged into the garbage heat treatment system for treatment. The high-temperature flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com