Nickel carbonyl synthesizer and synthesizing method of nickel carbonyl

A synthesis device and synthesis method technology, applied in the field of nickel refining, can solve the problems of single raw material and low synthesis efficiency of nickel carbonyl, and achieve the effects of sufficient raw material supply, improved environmental friendliness and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

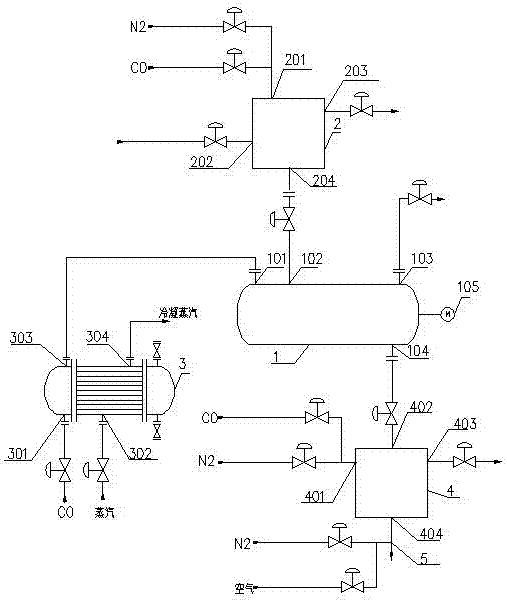

[0024] A method for using a nickel carbonyl synthesis device, comprising the following steps.

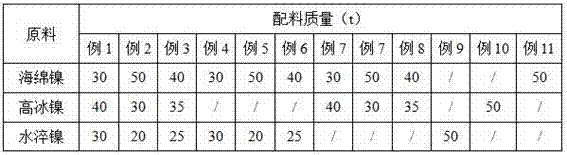

[0025] (1) Batching: batching according to the batching method of Example 1 in Table 1.

[0026] (2) Pretreatment: After the raw material composition configured in step 1 enters the raw material bin 2 each time, it first passes through the second air inlet 201 to the raw material bin 2 at room temperature N 2 Purge for 2 minutes, and then pass in CO with a temperature of 200°C for 1 minute; the working pressure of CO heater 3 is 0.8 MPa, and the working temperature of CO heater 3 is 200°C.

[0027] (3) Reaction: Add the pretreated raw material composition in step 2 into the horizontal synthesis kettle 1 through the first feed port 102, and add the preheated CO into the horizontal synthesis kettle 1 through the first air inlet 101 In the process, the stirring propulsion device 105 in the horizontal synthesis kettle 1 stirs and homogenizes the reactants, drives the generated carbonyl...

Embodiment 2

[0032] A method for using a nickel carbonyl synthesis device, comprising the following steps.

[0033] (1) Batching: batching according to the batching method of Example 2 in Table 1.

[0034] (2) Pretreatment: After the raw material composition configured in step 1 enters the raw material bin 2 each time, it first passes through the second air inlet 201 to the raw material bin 2 at room temperature N 2 Purge for 3 minutes, and then pass in CO with a temperature of 300°C for 0.5 minutes; the working pressure of CO heater 3 is 1.1 MPa, and the working temperature of CO heater 3 is 300°C.

[0035] (3) Reaction: Add the pretreated raw material composition in step 2 into the horizontal synthesis kettle 1 through the first feed port 102, and add the preheated CO into the horizontal synthesis kettle 1 through the first air inlet 101 In the process, the stirring propulsion device 105 in the horizontal synthesis kettle 1 stirs and homogenizes the reactants, drives the generated carbo...

Embodiment 3

[0039] A method for using a nickel carbonyl synthesis device, comprising the following steps.

[0040] (1) Batching: batching according to the batching method of Example 3 in Table 1.

[0041] (2) Pretreatment: After the raw material composition configured in step 1 enters the raw material bin 2 each time, it first passes through the second air inlet 201 to the raw material bin 2 at room temperature N 2 Purge for 1 minute, then pass in CO with a temperature of 100°C for 2 minutes; the working pressure of CO heater 3 is 0.6 MPa, and the working temperature of CO heater 3 is 100°C.

[0042] (3) Reaction: Add the pretreated raw material composition in step 2 into the horizontal synthesis kettle 1 through the first feed port 102, and add the preheated CO into the horizontal synthesis kettle 1 through the first air inlet 101 In the process, the stirring propulsion device 105 in the horizontal synthesis kettle 1 stirs and homogenizes the reactants, drives the generated carbonylated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com