Production method of selenium-enriched malt flour

A technology of selenium-enriched malt powder and production method, which is applied to fertilization methods, fertilizer mixtures, liquid fertilizers, etc., can solve the problems of falsely high selenium content and low substantial selenium content in selenium-enriched malt, and achieves an increase in the total selenium content. , good quality, the effect of improving the absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for producing selenium-enriched malt powder, comprising the following steps

[0019] (1) Plant selenium-enriched wheat, spray selenium-enriched water with a concentration of 20mg / Kg one week before the wheat blooms, and the spraying amount is 40-50Kg / mu, and harvest selenium-enriched wheat with a selenium content of 80-300ug / Kg;

[0020] (2) For germination of selenium-enriched wheat, soak the selenium-enriched wheat in 100-180mg / Kg selenium-enriched water and pack it into a germination box, keep the temperature in the germination box at 20-26°C, and carry out accelerated germination and germination without interruption Supplementary irrigation of selenium-enriched water until the wheat germinates, and after drying, selenium-enriched malt with a selenium content of 260-450mg / Kg is obtained;

[0021] (3) Fermentation and degradation of beneficial bacteria. After washing and beating the fermented malt, add edible beneficial bacteria and stir well. The amount of b...

Embodiment 2

[0025] For the test of comparing the germination of selenium-enriched wheat and ordinary wheat in 100-180mg / Kg selenium-enriched water:

[0026] Set A, B, C three groups of comparative tests, A group test adopts 100 selenium-enriched wheats planted in the method step (1) of the present invention, B group test adopts the method of the present invention, and reduce the selenium-enriched water to 2mg / Kg after planting 100 grains of wheat were produced, and 100 grains of common wheat were used in group C experiments.

[0027] Soak the wheat in groups A, B, and C respectively in 100-180mg / Kg selenium-enriched water and pack them into germination boxes, keep the temperature in the germination box at 20-26°C, accelerate germination, germinate, and germinate seeds The situation is shown in Table 1:

[0028] Table 1 The germination of three groups of wheat

[0029] time Germination amount of group A Germination amount of group B Germination amount of group C 3 day...

Embodiment 3

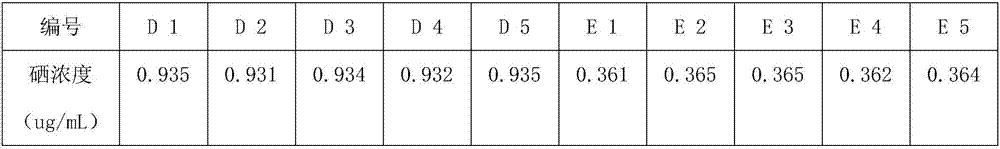

[0032] To step (3) whether reduce the verification test that inorganic selenium remains:

[0033] Set D, E two groups of contrast experiments, in D group test, adopt 1g malt powder of the present invention before fermentation, E group test adopt the malt powder obtained after same batch of 1g malt powder fermentation.

[0034] Divide the malt powder of the D and E groups into 5 parts, and fully dissolve them in 10mL of water. After standing still for 1 day, take 2mL of the supernatant to detect inorganic selenium. The experimental data obtained after the detection are shown in Table 2 :

[0035] Table 2 Inorganic selenium residues in the supernatants of the two groups of tests D and E

[0036]

[0037] As can be seen from Table 2, the residual amount of inorganic selenium in group E is far lower than that in the supernatant of group D, and step (3) of the present invention can indeed further improve the content of organic selenium and reduce the residual amount of inorgani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com