Anti-glare film

An anti-glare film and anti-glare technology, applied in optics, optical components, instruments, etc., can solve the problems of undescribed anti-glare laminates, etc., and achieve the effect of good touch and blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

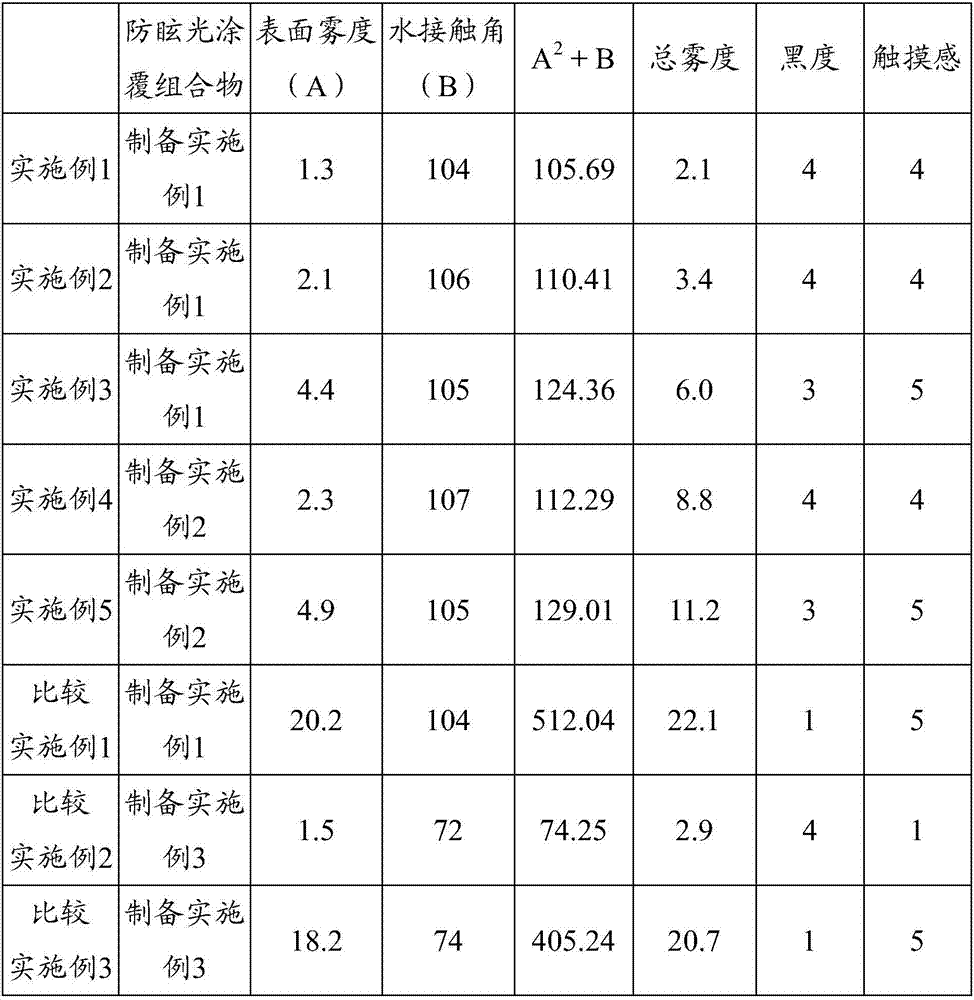

Examples

preparation Embodiment 1

[0081] Preparation Example 1: Preparation of Antiglare Coating Composition

[0082] Use a stirrer to mix 15 parts by weight of urethane acrylate (SC2153, Miwon Specialty Chemicals), 15 parts by weight of pentaerythritol triacrylate (M340, Miwon Specialty Chemicals), 1 part by weight of light-transmitting particles (acrylic styrene copolymer, 1.51 Refractive index, average diameter of 4.5 μm), 30 parts by weight of methyl ethyl ketone (Daejung Chemicals & Materials), 36 parts by weight of propylene glycol monomethyl ether (Daejung Chemicals & Materials), 2.5 parts by weight of photoinitiator (I-184, Ciba) and 0.5 parts by weight of antifouling agent (Optool TM DAC-HP, Daikin), and filtered through a polypropylene filter to obtain an anti-glare coating composition.

preparation Embodiment 2

[0083] Preparation Example 2: Preparation of Antiglare Coating Composition

[0084]Mix 15 parts by weight of urethane acrylate (SC2153, Miwon Specialty Chemicals), 15 parts by weight of pentaerythritol triacrylate (M340, Miwon Specialty Chemicals), 1 part by weight of light-transmitting particles (acrylic styrene copolymer, 1.55 Refractive index, average diameter of 4.5 μm), 30 parts by weight of methyl ethyl ketone (Daejung Chemicals & Materials), 36 parts by weight of propylene glycol monomethyl ether (Daejung Chemicals & Materials), 2.5 parts by weight of photoinitiator (I-184, Ciba) , and 0.5 parts by weight of antifouling agent (Optool TM DAC-HP, Daikin), and filtered through a polypropylene filter to obtain an anti-glare coating composition.

preparation Embodiment 3

[0085] Preparation Example 3: Preparation of Antiglare Coating Composition

[0086] Use a stirrer to mix 15 parts by weight of urethane acrylate (SC2153, Miwon Specialty Chemicals), 15 parts by weight of pentaerythritol triacrylate (M340, Miwon Specialty Chemicals), 1 part by weight of light-transmitting particles (acrylic styrene copolymer, 1.51 Refractive index, average diameter of 4.5 μm), 30 parts by weight of methyl ethyl ketone (Daejung Chemicals & Materials), 36 parts by weight of propylene glycol monomethyl ether (Daejung Chemicals & Materials), 2.5 parts by weight of photoinitiator (I-184, Ciba) and 0.5 parts by weight of a leveling agent (BYK-3530, BYK), and filtered through a polypropylene filter to obtain an anti-glare coating composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com