Heat storage container and heat storage device provided with heat storage container

A heat storage and container technology, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as limitation and reduction of heat transfer volume of heat exchange medium, and shape damage of chemical heat storage materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

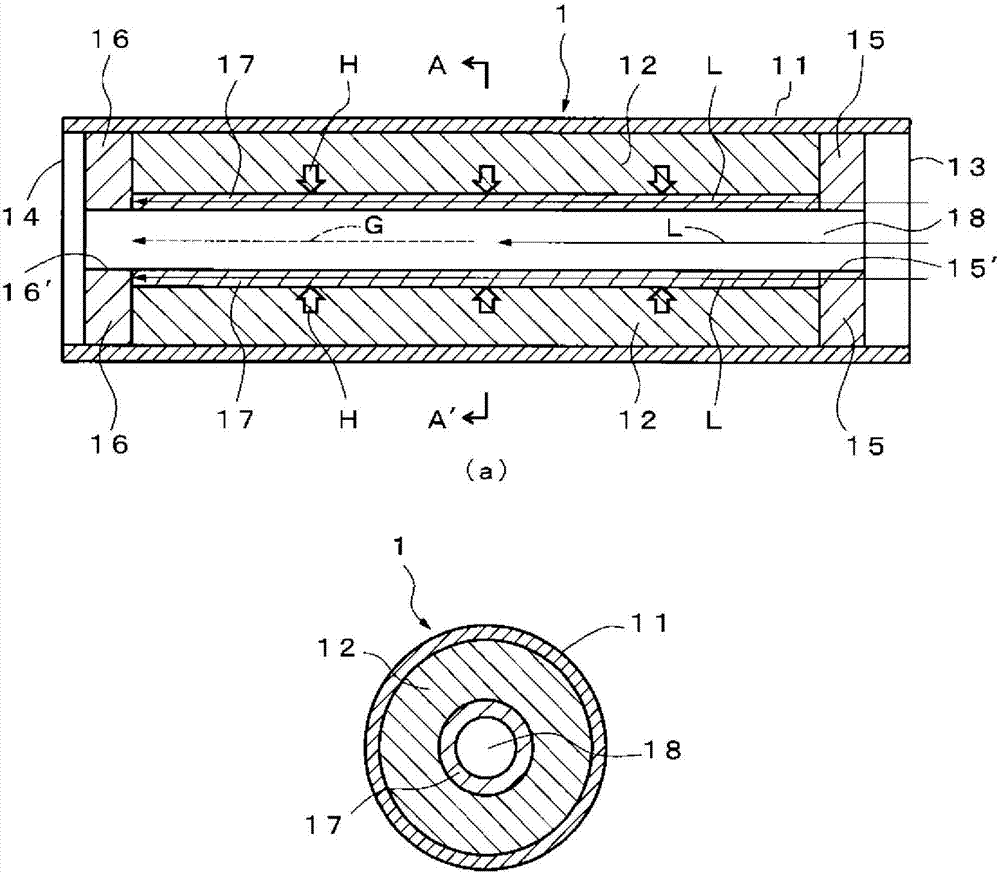

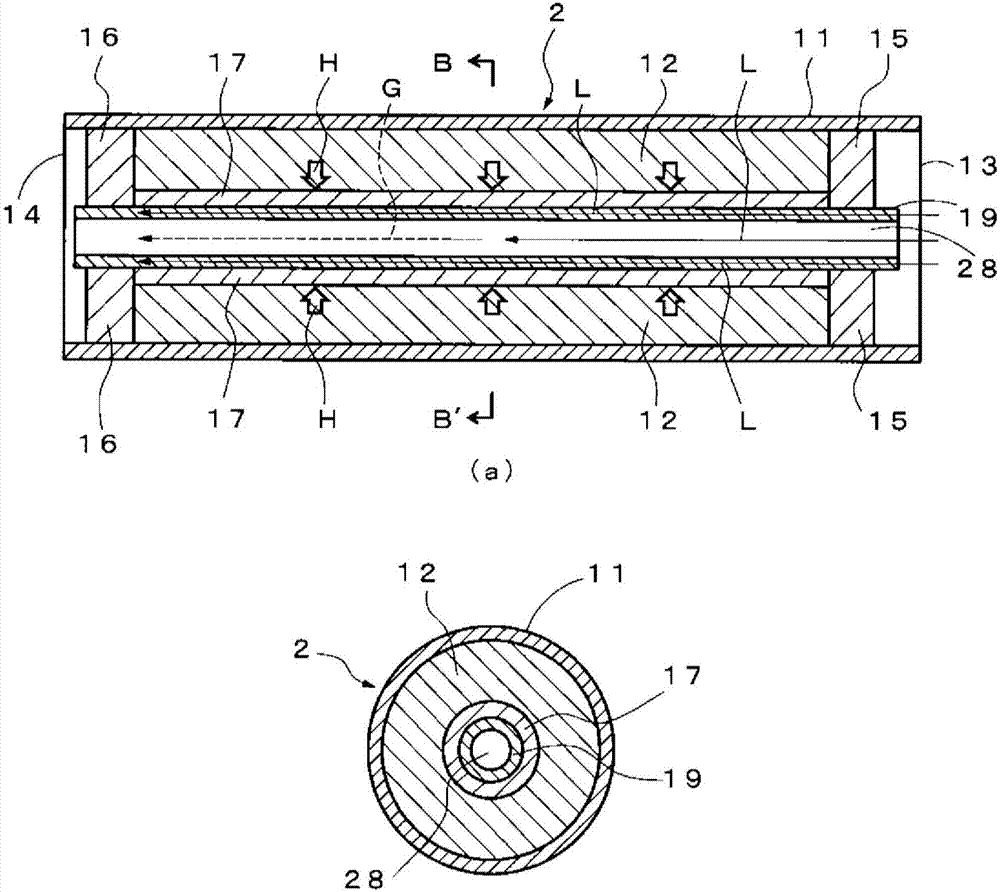

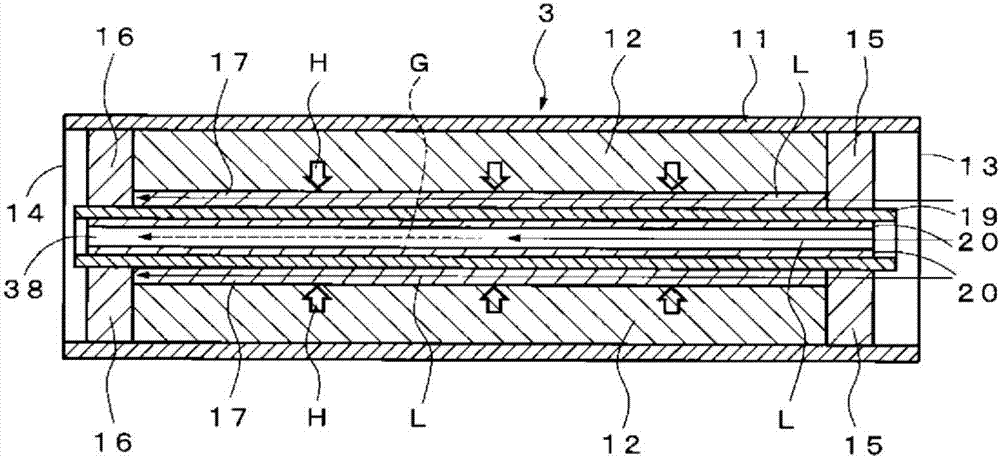

[0069] Next, the thermal storage container according to the first embodiment of the present invention will be described with reference to the drawings. like figure 1 As shown in (a), the heat storage container 1 according to the first embodiment includes: a cylindrical body 11 which is a tubular body with openings at both ends; internal. In addition, the heat storage container 1 includes: a first cover 15, which is arranged adjacent to the one end 13 side of the cylindrical body 11 of the chemical heat storage material 12, and is made of a porous body; a second cover 16, which The other end portion 14 of the cylindrical body 11 of the chemical heat storage material 12 is disposed adjacent to and made of a porous body; The diffusion layer for transporting the liquid disposed adjacent to the inner side surface of the chemical heat storage material 12 between the second covers 16 has a capillary structure.

[0070] like figure 1 As shown in (b), the radial cross section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com