Fan case for an aircraft engine

A technology for aircraft engines and fans, applied in the directions of machines/engines, engine components, liquid fuel engines, etc., can solve the problems of complex manufacturing, and achieve the effect of improving strength, simplifying installation process, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

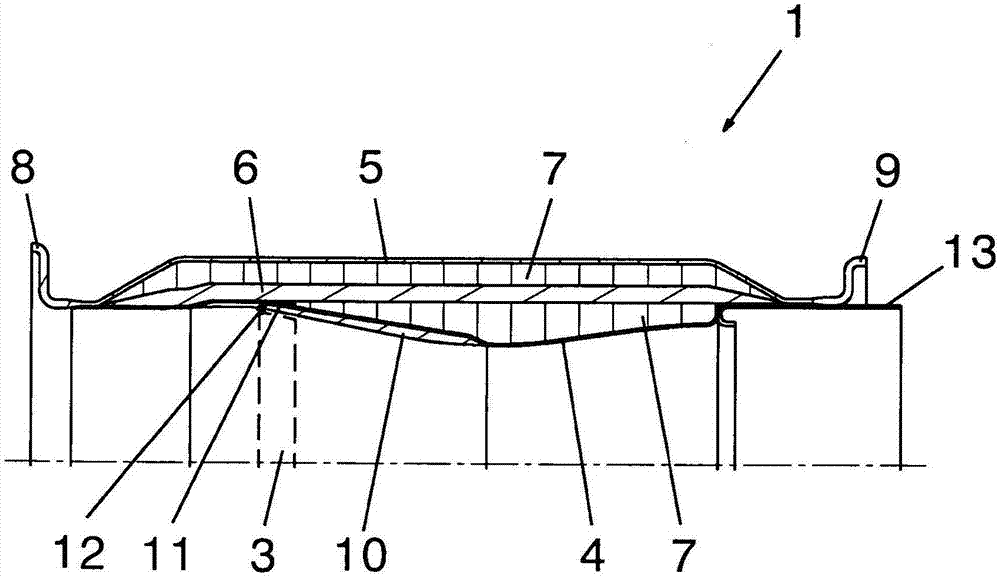

[0023] figure 1 An aircraft engine 2 with a fan housing 1 arranged in the region of the fan 3 is shown in a partially sectioned view. Usually the fan housing 1 comprises a cylindrical casing 1 with a fixing flange and possibly stiffening ribs or the like integrated or fastened thereto. The fan housing 1 is connected to the rest of the engine housing, which in turn is arranged on a corresponding fastening element, usually an airfoil.

[0024] figure 2 A section of a fan housing 1 constructed according to the invention is shown in section. The fan housing 1 includes an inner layer 4 and an outer layer 5 designed according to the aerodynamic requirements of the aircraft engine 2 and a reinforcing layer 6 arranged between the inner layer 4 and the outer layer 5 and deformation layers arranged on both sides of the reinforcing layer 6 7. Depending on the aircraft engine 2 , the reinforcement layer 6 consists of at least 20 layers of glass-fibre-reinforced plastic and serves pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com