Testing device and method of corrosion deterioration for concrete panels under complex action

A concrete panel and test device technology, which is applied in the field of simulation tests, can solve the problems of high device cost, bulky and inconvenient devices, and achieve the effect of increasing test accuracy, improving test accuracy, and ensuring smooth loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with embodiment the present invention will be further described.

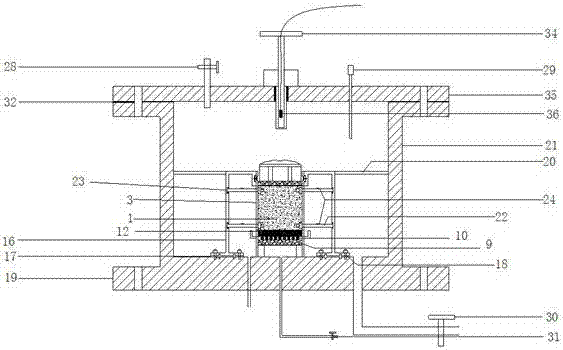

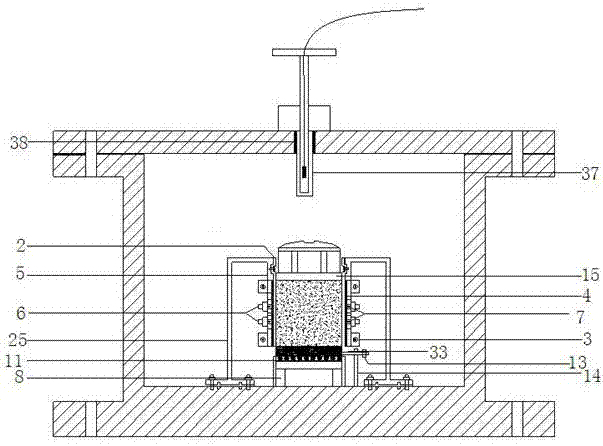

[0047] like Figure 1-4 As shown, a concrete panel corrosion degradation test device under complex action includes a sealed chamber, an isolation chamber and a dissolution chamber, the sealing chamber is provided with an isolation chamber, and the isolation chamber is provided with a corrosion chamber;

[0048] The corrosion chamber includes a high-elastic rubber tube 2, a base 8 arranged from bottom to top in the high-elastic rubber tube 2, a lower permeable stone 9, a steel ball track 11, stainless steel beads 10, a cushion block 12, and a concrete panel test piece 1 And the upper permeable stone 15, the base 8 is installed on the bottom plate 19 of the sealed chamber;

[0049] The two opposite side walls of the outer high elastic rubber tube 2 of the concrete panel test piece 1 are tension surfaces, and the other two opposite side walls of the outer high elastic rubber tube 2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com