Target type flow sensor and target type flow meter for measuring quality and flow of steam of thermal production well

A technology of mass flow and target flow, which is applied to mass flow measurement devices, direct mass flow meters, etc., to achieve the effects of low speed, small measurement error, and small movable displacement

Pending Publication Date: 2017-08-29

JINGZHOU MINGDE TECH CO LTD

View PDF16 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing target-type flow sensor has a structural form in which the force-measuring mechanism is installed from the side of the measuring tube, which is not suitable for use in small and deep wells and high-temperature, high-pressure, and high-humidity working conditions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0032] It should be noted that the words indicating orientation such as "front" and "rear" in this embodiment are relative to the flow direction of the fluid.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

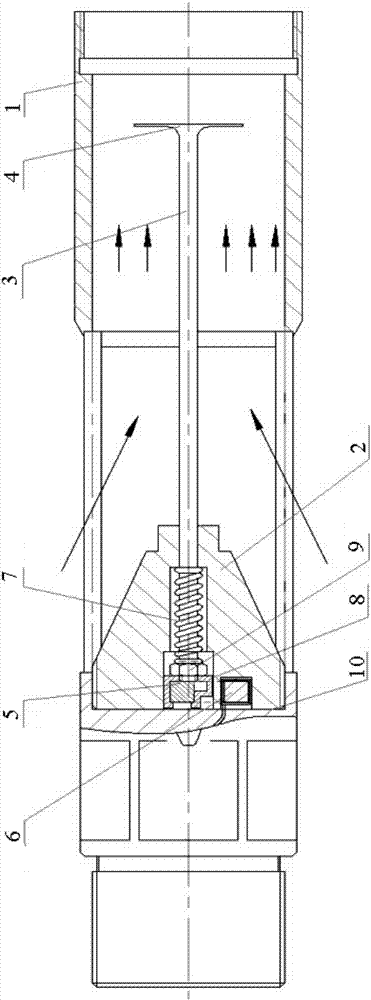

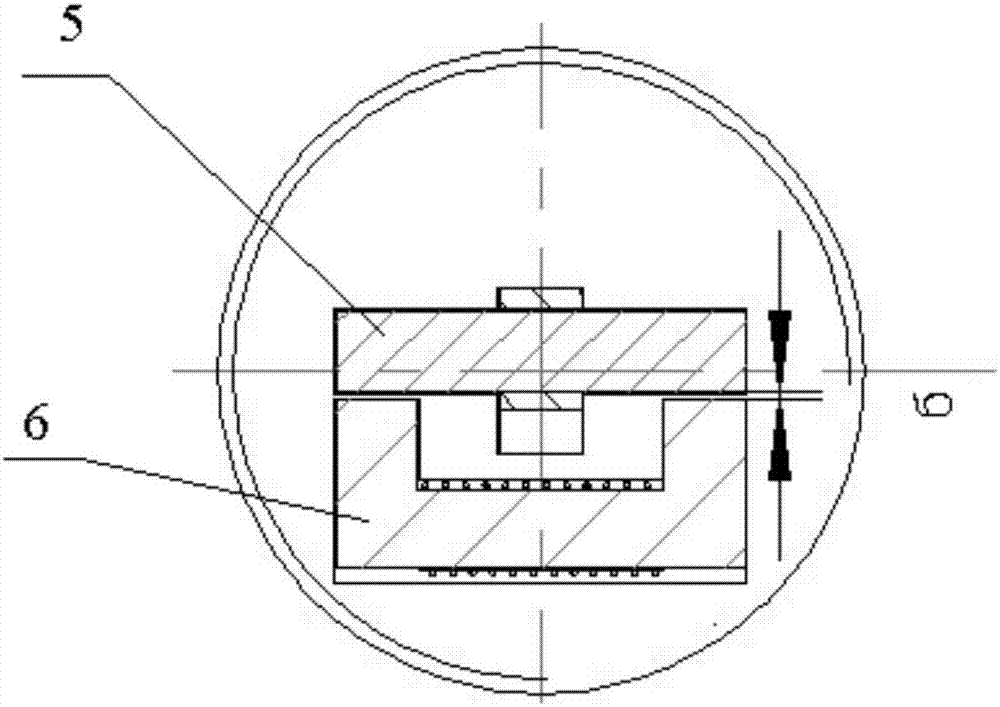

The invention discloses a target type flow sensor and a target type flow meter for measuring quality and flow of steam of a thermal production well, and belongs to the technical field of fluid quality and flow measuring devices. The target flow sensor for measuring quality and flow of the steam of the thermal production well comprises a barrel, a limiting seat and a target guide rod, wherein a fluid inlet is formed in the barrel; the limiting seat is arranged on the inner wall of the barrel; the target guide rod is arranged in the axial direction of the barrel and penetrates in the limiting seat; a target slice is arranged at the front end of the target guide rod; a moving magnetic core is arranged at the rear end of the target guide rod; an elastic element which is positioned on the outer side of the target guide rod is arranged between the moving magnetic core and the limiting eat; a fixed magnetic core inductor which is positioned on the outer side of the moving magnetic core is further arranged in the barrel; the fixed magnetic core inductor and the moving magnetic core form a closed magnetic circuit; fluid can push the target guide rod to move so as to change facing area and inductance value of the moving magnetic core and the fixed magnetic core inductor. The target type flow sensor is in an axial built-in type, occupies small space in the transverse direction, and is suitable for narrow space such as underground space.

Description

technical field [0001] The invention relates to the technical field of fluid mass flow measurement devices, in particular to a target flow sensor for measuring steam mass flow in thermal recovery wells and a target flow meter including the target flow sensor. Background technique [0002] With the increasing depletion of conventional crude oil resources, the exploitation of abundant heavy oil or heavy oil resources by thermal oil recovery is an important measure and a promising development direction for increasing crude oil production in oilfields. In thermal oil recovery, steam huff and puff and steam flooding are widely used in oil recovery. Both of them need to inject high-temperature and high-pressure steam into the steam injection well, so that the steam can penetrate into the oil reservoir, and transfer the steam displacement and heat to the steam injection well. Viscous oil can reduce its viscosity, thermally expand and partially gasify, seep out from pores and remove...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01F1/80

CPCG01F1/80

Inventor 袁伯利王雄戴刚郑俊刘伟许军王才美

Owner JINGZHOU MINGDE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com