Vehicle lamp heater and vehicle lamp

A technology of heaters and heating resistors, which is applied in the direction of headlights, lighting and heating equipment, cooling/heating devices of lighting devices, etc., can solve problems such as long time, achieve effective heat transfer and improve heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

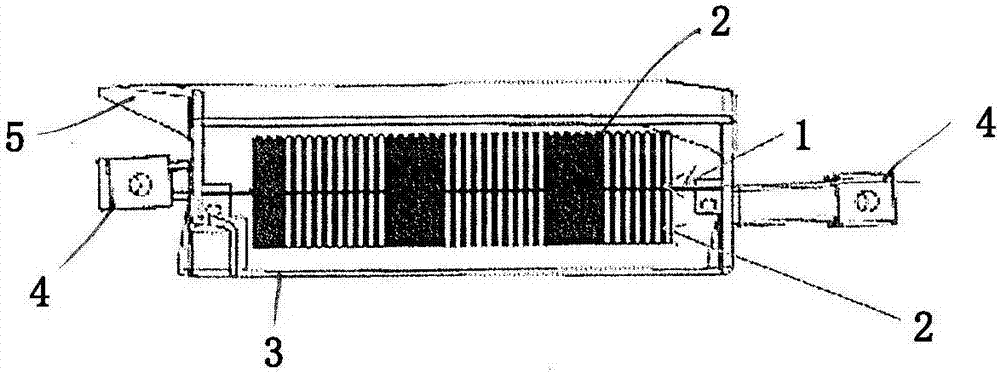

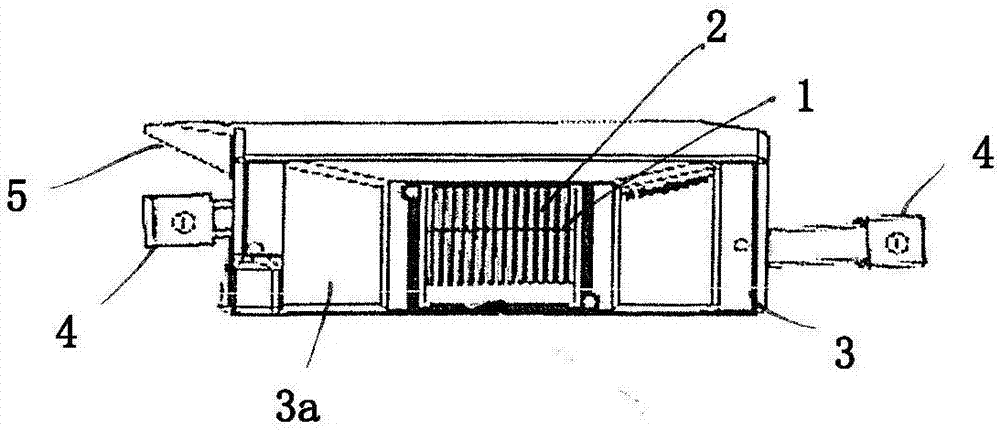

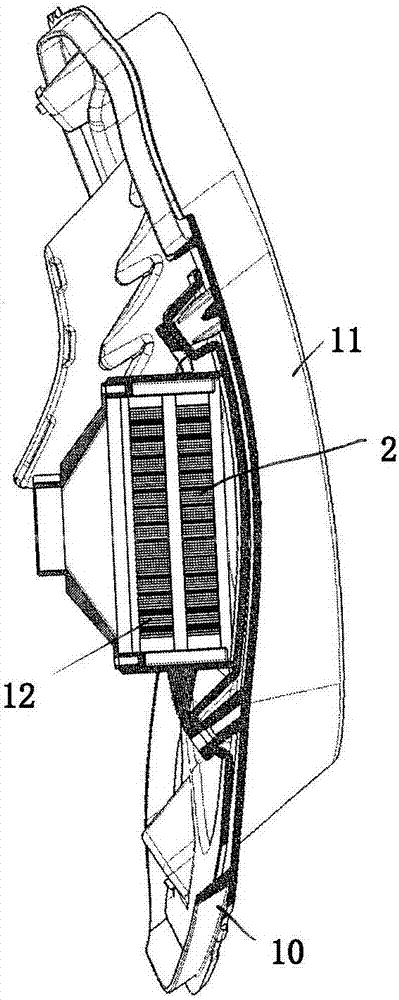

[0019] figure 1 The car lamp heater shown in includes: a polymer PTC heating resistor 1 , two metal cooling bodies 2 , and a holder 3 for holding the polymer PTC heating resistor 1 and the cooling bodies 2 . The bracket 3 is made of plastic, for example PC, PA66, PBT or other thermoplastic, and comprises an attachment element 4 for fixing the bracket to the housing of the vehicle light. The attachment elements may eg comprise eyelets or flanges.

[0020] Polymer PTC heating resistors have metal coatings on opposite sides. Terminals for connection to a power source, such as the vehicle electrical system, may be attached to the metal coating, for example by soldering or welding.

[0021] A polymer PTC heating resistor can be a layer arranged between two metal plates. The polymer PTC heating resistor is electrically insulated from the cooling body 2 , for example by an electrically insulating adhesive or glue covering the metallic coating of the PTC heating resistor. The heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com