Asymmetrical rotor electric eddy current damper

An eddy current damper, asymmetric technology, used in textile cables, springs/shock absorbers, non-rotational vibration suppression, etc. Safety, increased cycle time, improved safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

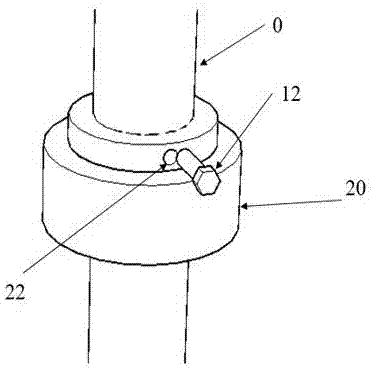

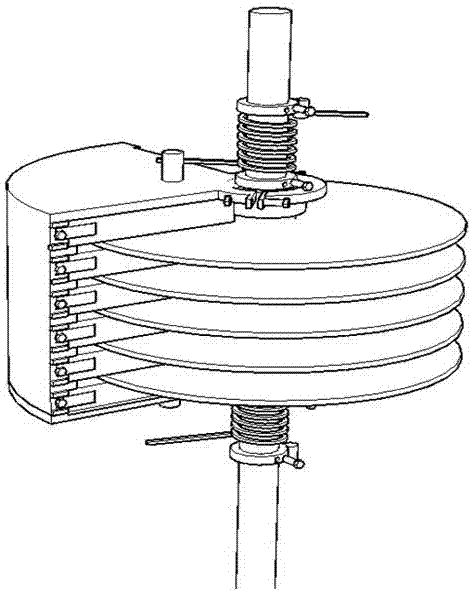

[0028] The control system for suppressing structural vibration in this embodiment is as follows: Figure 1-Figure 12 shown. It is composed of rotor, copper sheet 30, torsion spring 40, bearing 20 and various connecting parts. The rotor includes a casing 10, a magnet 18, a casing collar 11, and a baffle 13; the copper sheet 30 is fixed on the positioning tube 31; the bearing 20 is provided with a positioning hole 22 for positioning, and is fixed on the cable 0 with screws 12 ;The shell includes a positioning groove 17, a rear baffle 16 and an anti-rotation limiting bar 14; in order to fix the spring position, a spring positioning ring 41 is also fixedly connected to the cable 0; and the positioning ring 41 is provided with a limiting torsion spring The torsion-limiting nail 42 of 40 cooperates with the limiting nail 15 of the shell; the magnet 18 is mainly fixed by the positioning groove 17, and then further fixed by the baffle plate. Since the rotor can only do centrifugal mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com