Steel bar suitable for concrete

A technology of concrete and steel bars, applied to structural elements, building components, building reinforcements, etc., can solve problems such as inability to achieve firm strength, unreasonable structure, easy release, fracture, and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

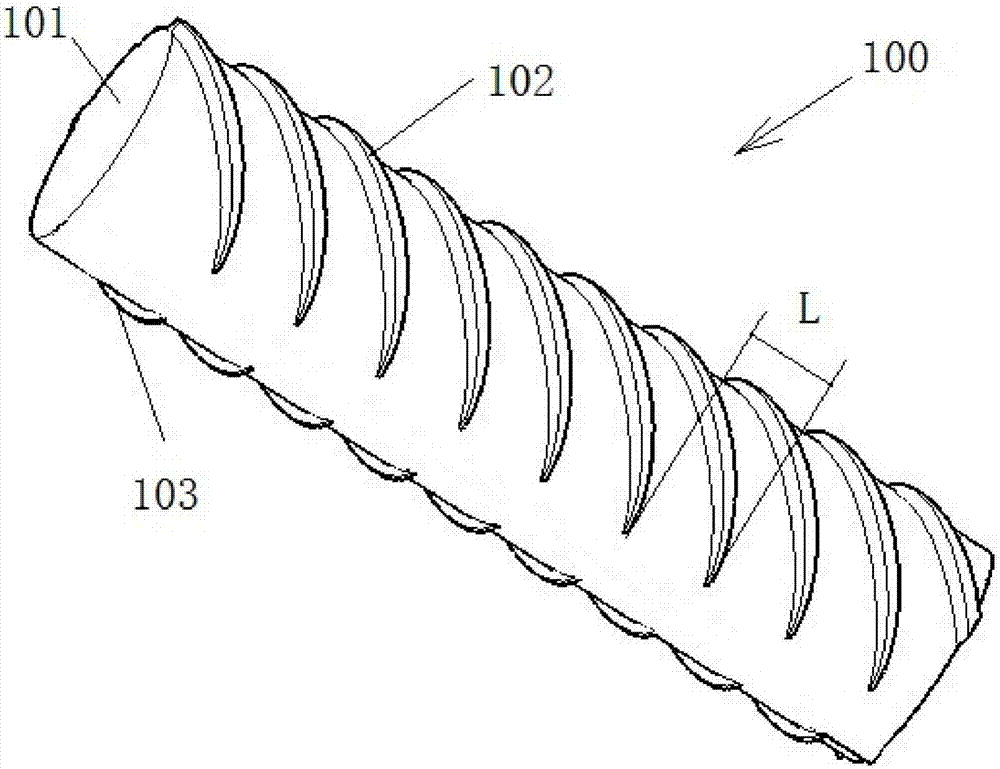

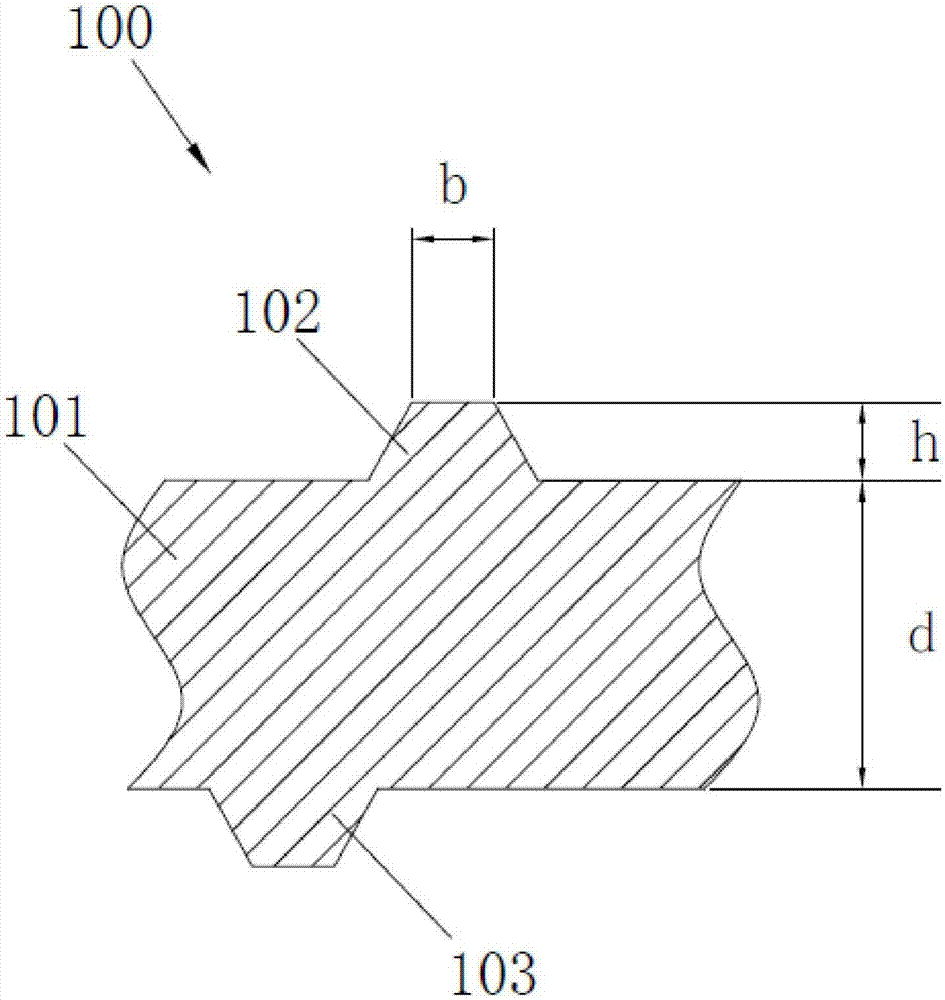

[0050] Such as figure 1 As shown, the steel bar 100 suitable for concrete includes a steel bar body 101 and several transverse ribs 102 and 103 distributed along the length direction of the steel bar body. The transverse ribs 102, 103 protrude from the steel bar body 101. is d, the maximum dimension of the transverse ribs 102, 103 protruding from the steel bar body 101 is h, and the width of the top of the transverse ribs 102, 103 protruding from the steel bar body is defined as the width b of the rib top, which corresponds to the length direction of the steel bar body 101 The distance between two adjacent transverse ribs is defined as the rib spacing L.

[0051] Such as figure 1 with figure 2 As shown, the transverse ribs are divided into two groups of transverse ribs 102 and transverse ribs 103 , which are respectively arranged on both sides of the steel bar body 101 . The portion of the rebar body 101 between the two sets of transverse ribs 102 and 103 is smooth. Speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com