Rectifier units for turbomachines

A technology of turbine units and rectifiers, which is applied to components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., and can solve problems such as engulfment, gaps, and screw head separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

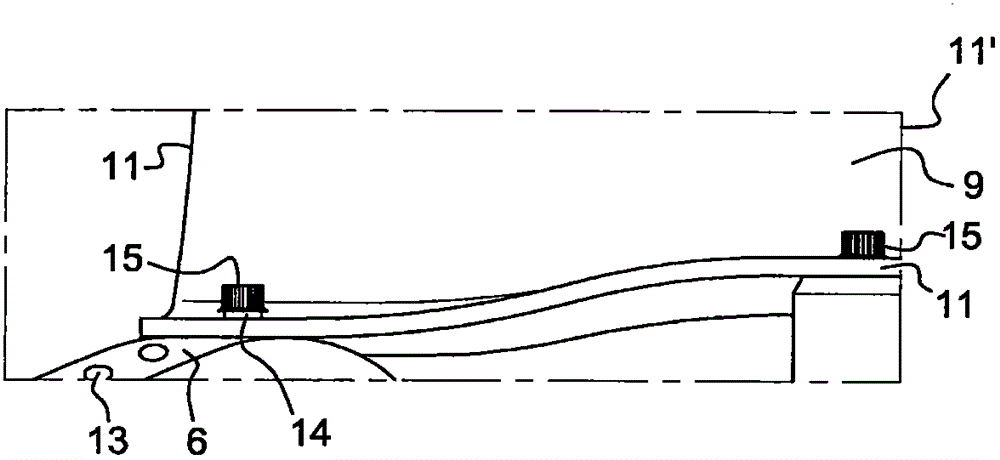

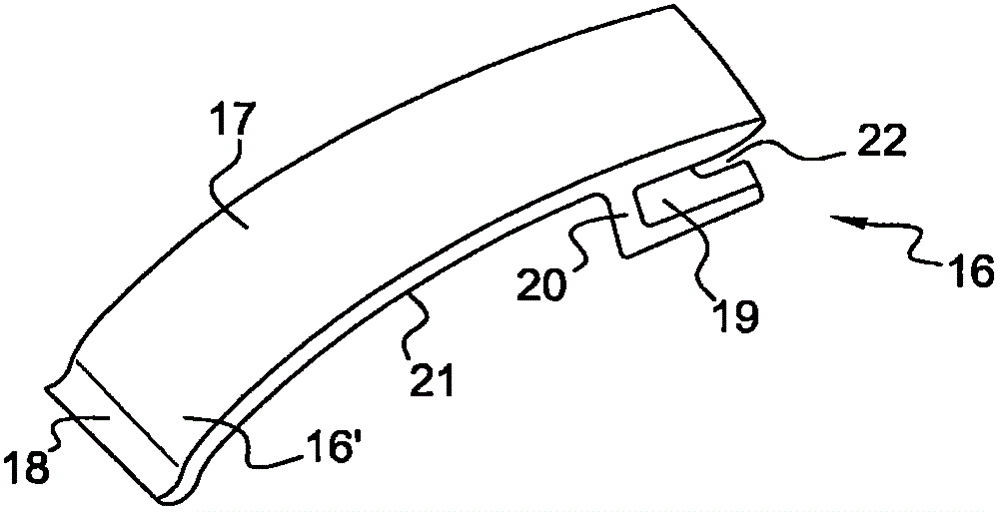

[0045] For reasons of clarity, only elements necessary for the understanding of the invention are shown, not to scale, but only in a schematic manner. Also, phase diagram elements found in different figures have the same reference numerals.

[0046] For the following description, it should be understood that the gas passes upstream of the turbojet engine (turbine block), traveling to the downstream side of the latter, each element is indicated by the reference sign "X", and the upstream side of each element is indicated by The reference "X" followed by a single prime is indicated; the downstream side of each element is indicated by the reference "X" followed by two primes.

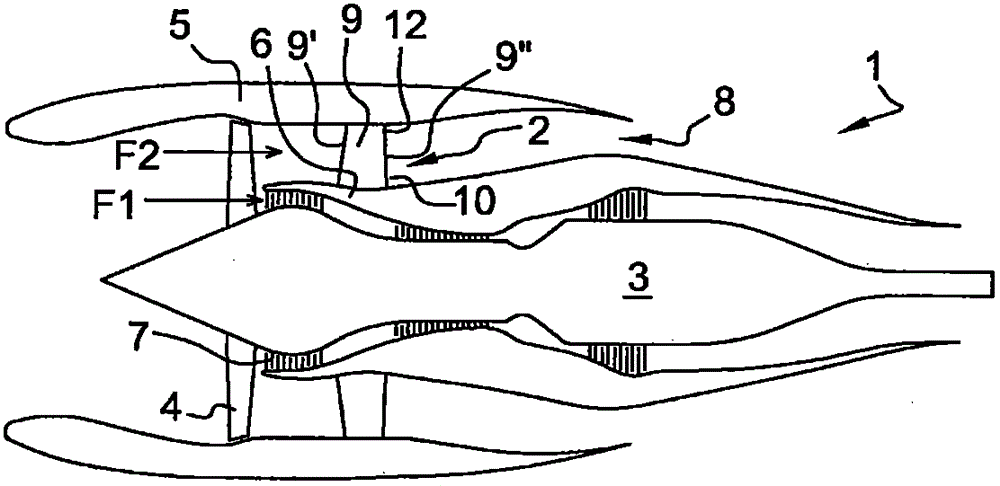

[0047] figure 1 A schematic twin-flow turbojet engine 1 is shown. This twin-flow turbojet engine 1 notably comprises a rectifier 2 according to the invention. The turbojet engine 1 further comprises an electric motor 3 with a front mounted fan 4 surrounded by a casing ring 5 (forming the fan case in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com