Hot-rolled ribbed steel bar

A technology of ribbed steel bars and steel bars, applied in structural elements, building components, building reinforcements, etc., can solve problems such as unreasonable structure, easy release and fracture, collapse, and failure to achieve firm strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

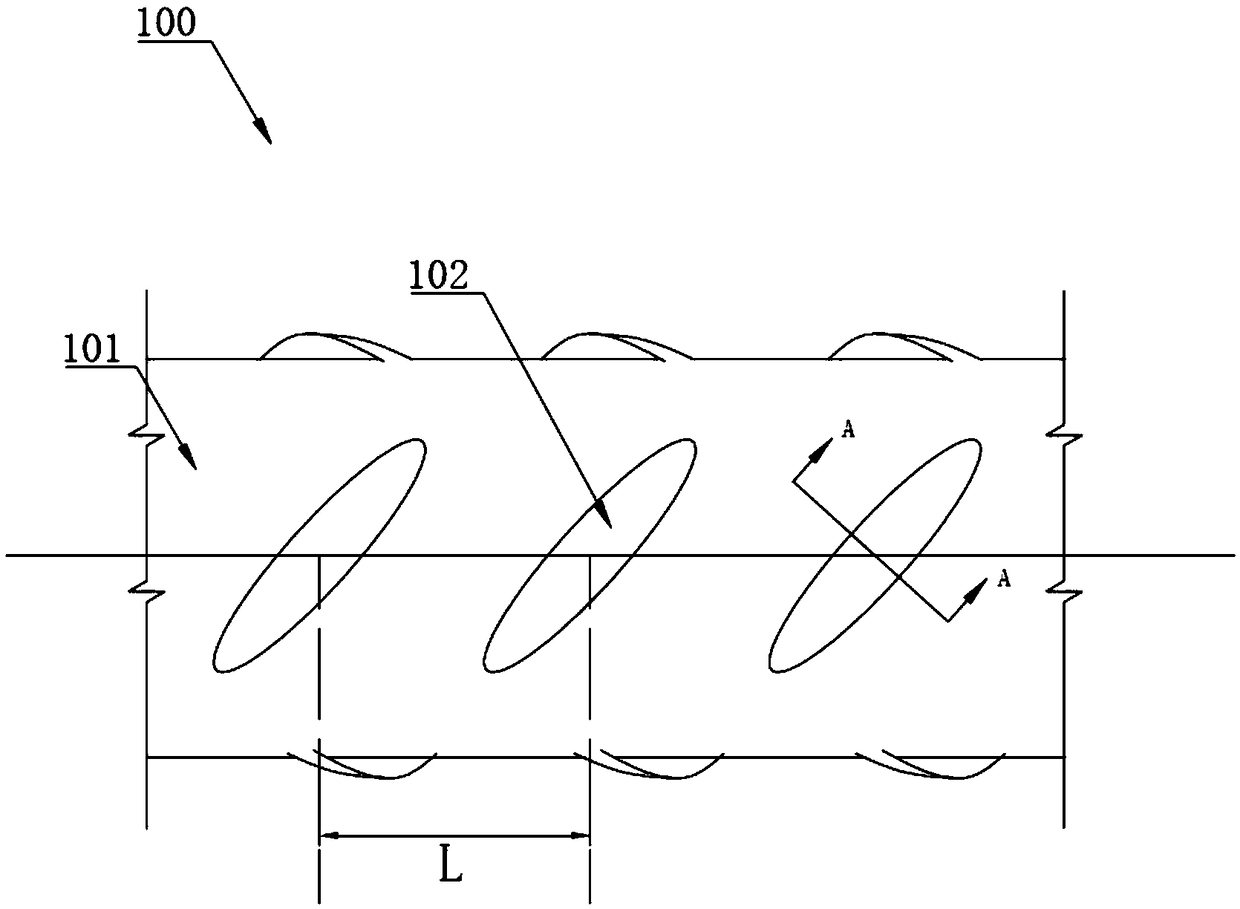

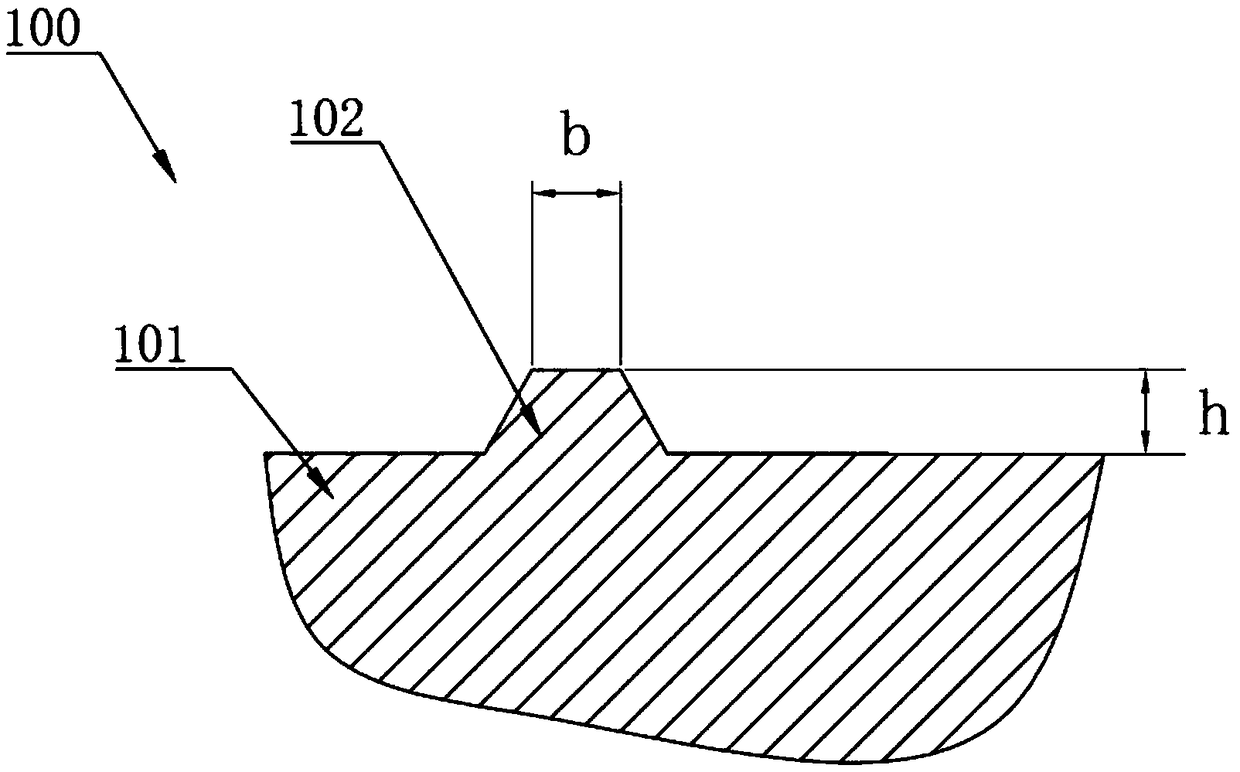

[0094] Such as figure 1 As shown, the hot-rolled ribbed steel bar 100 includes a steel bar body 101 and several transverse ribs 10 distributed along the length direction of the steel bar body. The transverse ribs 102 protrude from the steel bar body 101. The maximum dimension of the rib 102 protruding from the steel bar body 101 is h, the width of the top of the transverse rib 102 protruding from the steel bar body is defined as the rib top width b, between two adjacent transverse ribs in the length direction of the steel bar body 101 The distance is defined as the rib spacing L.

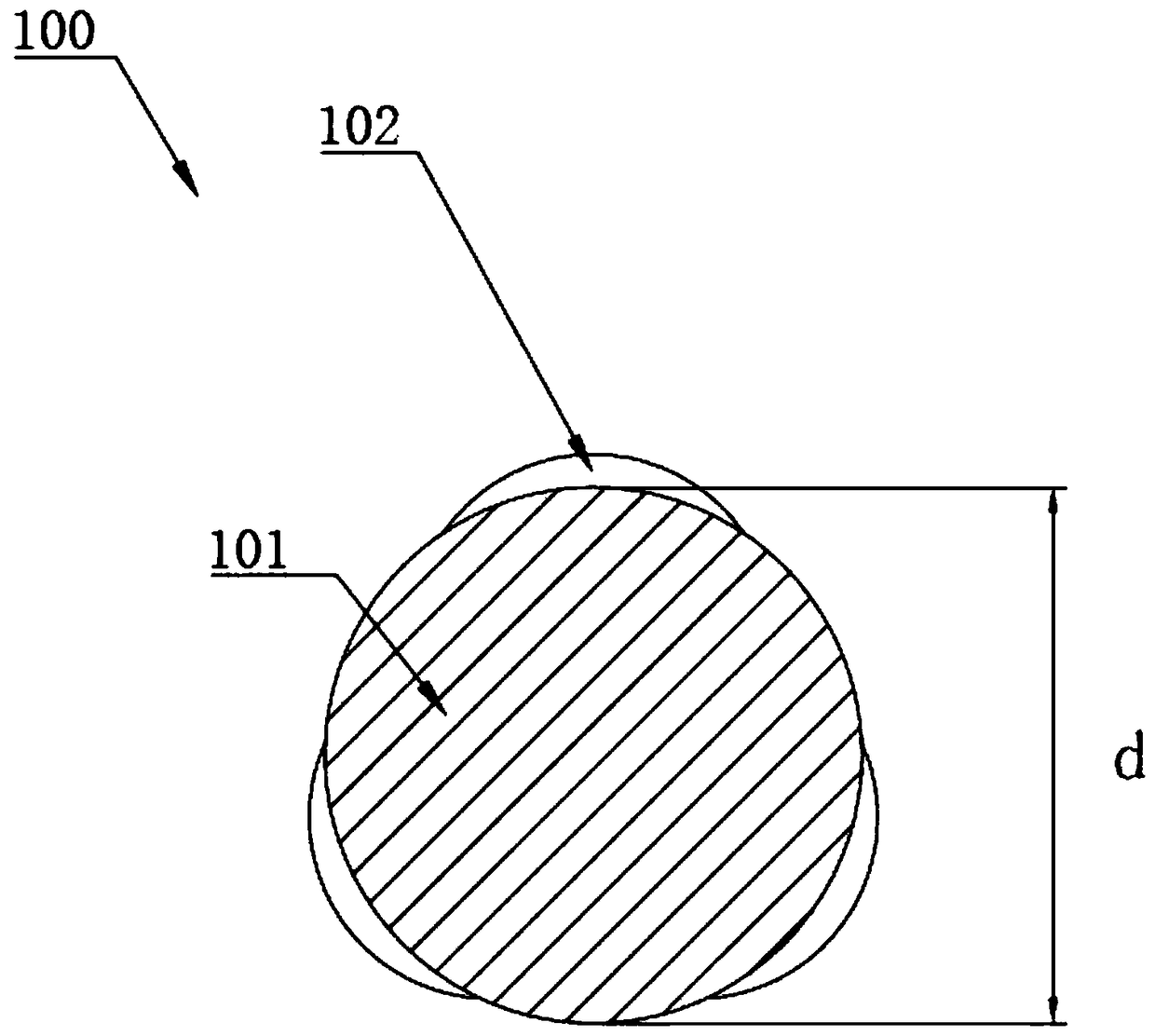

[0095] Such as figure 2 As shown, viewed from the cross-section of the steel bar body 101 , the transverse ribs 102 are divided into three groups and evenly distributed on the outer periphery of the steel bar body 101 . The part of the steel bar body 101 between any two sets of transverse ribs 102 is smooth. The profile of the outer periphery of the reinforcing bar body 101 between the transvers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Biggest size | aaaaa | aaaaa |

| Biggest size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com