Phenyl silicone rubber nano composite material and preparation method of same

A nano-composite material, phenyl silicone rubber technology, applied in the field of phenyl silicone rubber nano-composite materials and its preparation, can solve the problems of low aging resistance, easy crushing of products, general wear resistance, etc., and achieve improved aging resistance , Improve air tightness, improve the effect of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

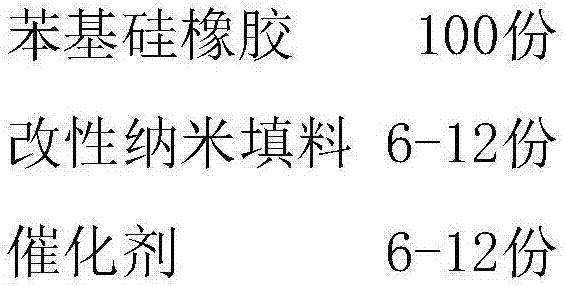

[0045] A phenyl silicone rubber nanocomposite material, which is composed of the following parts by mass:

[0046]

Embodiment 2

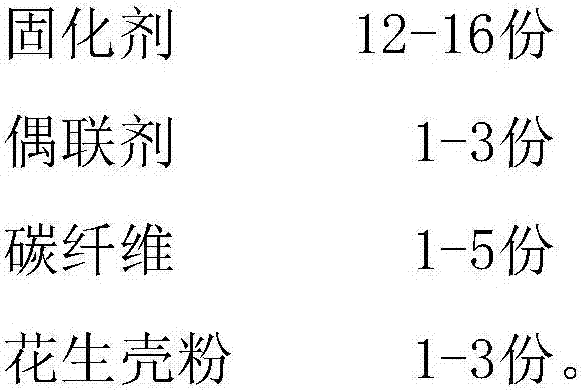

[0048] A phenyl silicone rubber nanocomposite material, which is composed of the following parts by mass:

[0049]

Embodiment 3

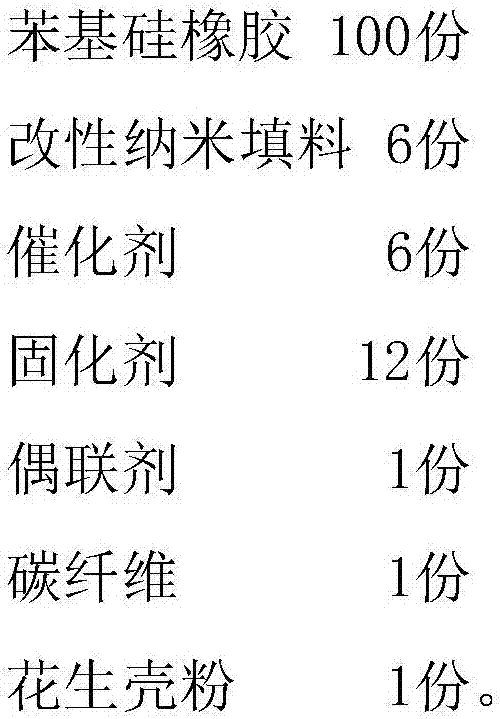

[0051] A phenyl silicone rubber nanocomposite material, which is composed of the following parts by mass:

[0052]

[0053] In the above embodiment, the modified nano filler is one or more of modified nano silica or modified mica powder.

[0054] In the above embodiment, the catalyst is nano zinc oxide.

[0055] In the above embodiment, the curing agent is sulfur.

[0056] In the above embodiment, the coupling agent is a silane coupling agent.

[0057] In the above embodiment, the peanut shell powder is a phenolic substance extracted from peanut shells (for example, Yang Yunxu's technical literature published in "Extraction of Phenolic Substances from Peanut Shells" in the third issue of 1994 has made clear that this The extraction method and application of the substance; and such as: Ji Rencai, Lv Jinkui, Wang Chunju, etc., also disclosed the extraction of the substance in the technical document "Extracting phenolic compounds from peanut shells and peanut shell phenolic phenol formald...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com