Preparation method of nanometer silica-based material

A technology based on nano-silicon, which is applied in the field of energy storage research, can solve the problems of restricting the widespread use of silicon-based negative electrode materials, the high price of nano-silicon-based materials, and the difficulty of nano-level crushing, and achieves low preparation costs and easy large-scale Production, low stress relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

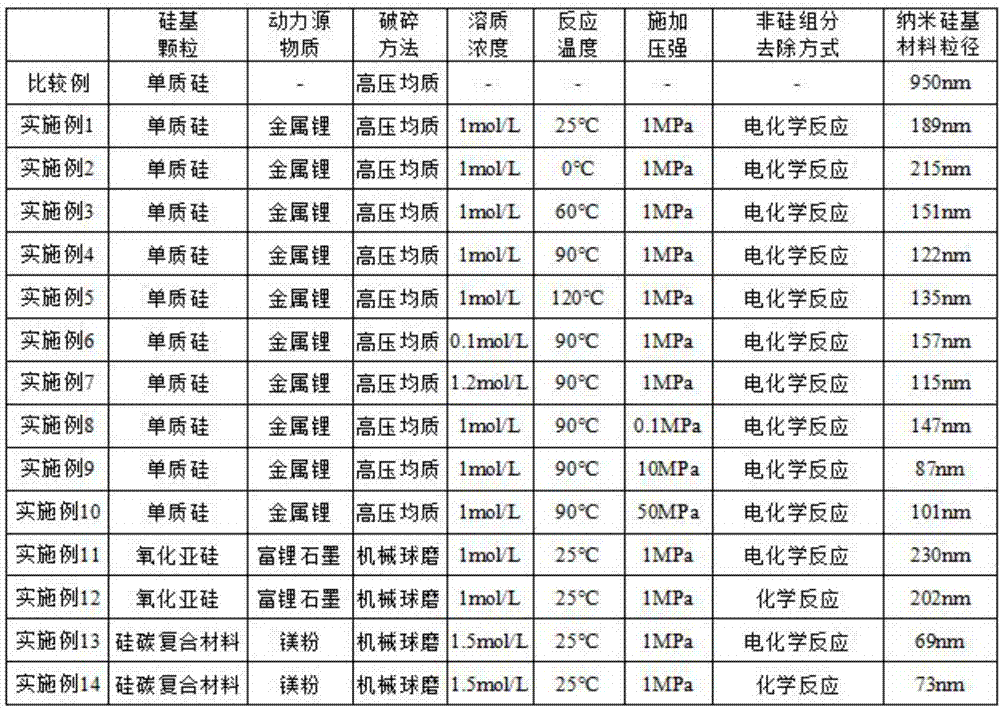

Examples

Embodiment 1

[0029] Step 1, alloy preparation: select elemental silicon with a particle diameter of 50 μm, metal lithium, and 1mol / L lithium hexafluorophosphate as the electrolyte and mix the lithium ion battery electrolyte evenly, and apply a pressure of 1 MPa to the mixture, and then fully react at 25°C. Lithium ions are intercalated into elemental silicon particles to obtain silicon-based alloy particles.

[0030] Step 2, crushing: in an inert atmosphere, the silicon-based alloy particles obtained in step 1 are subjected to high-pressure homogenization (ie, the particles are subjected to high-speed impact) treatment (same as the comparative example), to obtain crushed nano-sized silicon-based alloy particles.

[0031] Step 3, preparation of nano-silicon-based particles: Mix the nano-sized silicon-based alloy particles obtained in step 2 with a conductive agent to prepare an electrode, and assemble it with a lithium-ion battery electrolyte and a copper current collector as a counter elect...

Embodiment 2

[0033] The difference from Example 1 is that this example includes the following steps: In step 1, select elemental silicon with a particle diameter of 50 μm, metallic lithium, and 1 mol / L lithium hexafluorophosphate as electrolytes for lithium-ion batteries and mix them evenly, and mix the mixture evenly. Apply a pressure of 1MPa, and then fully react at 0°C, so that lithium ions are intercalated into elemental silicon particles to obtain silicon-based alloy particles.

[0034] Others are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0036] The difference from Example 1 is that this example includes the following steps: In step 1, select elemental silicon with a particle diameter of 50 μm, metallic lithium, and 1 mol / L lithium hexafluorophosphate as electrolytes for lithium-ion batteries and mix them evenly, and mix the mixture evenly. Apply a pressure of 1 MPa, and then fully react at 60°C, so that lithium ions are intercalated into the elemental silicon particles to obtain silicon-based alloy particles.

[0037] Others are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com