PLC hardware realization method for Petri net model of workshop manufacturing system

A technology for manufacturing systems and workshops, applied in instrumentation, design optimization/simulation, computing, etc., to resolve conflicts and other issues, and achieve the effects of resolving transition conflicts, resolving avalanche effects, and improving system security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

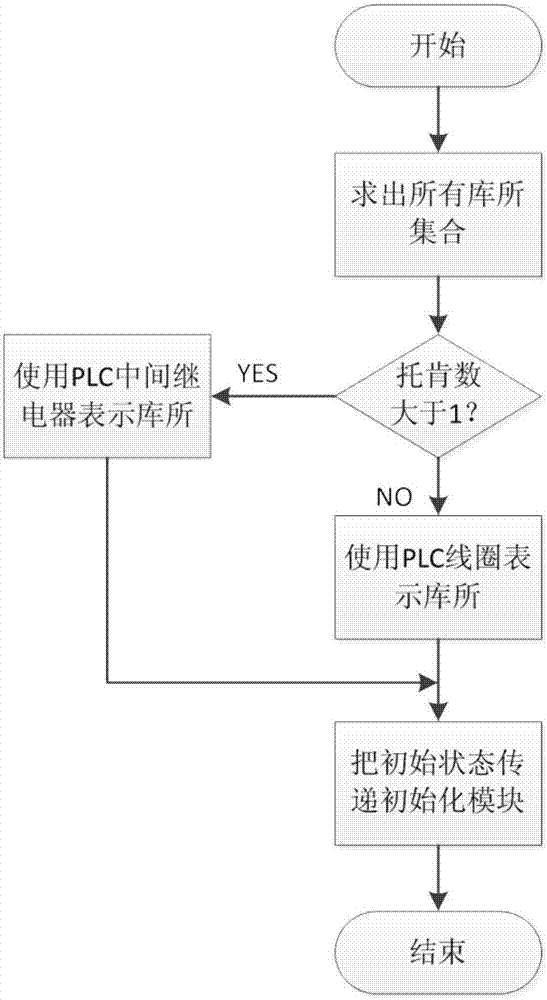

[0068] A method for converting Petri nets to PLC ladder diagrams in a workshop manufacturing system, comprising the following steps:

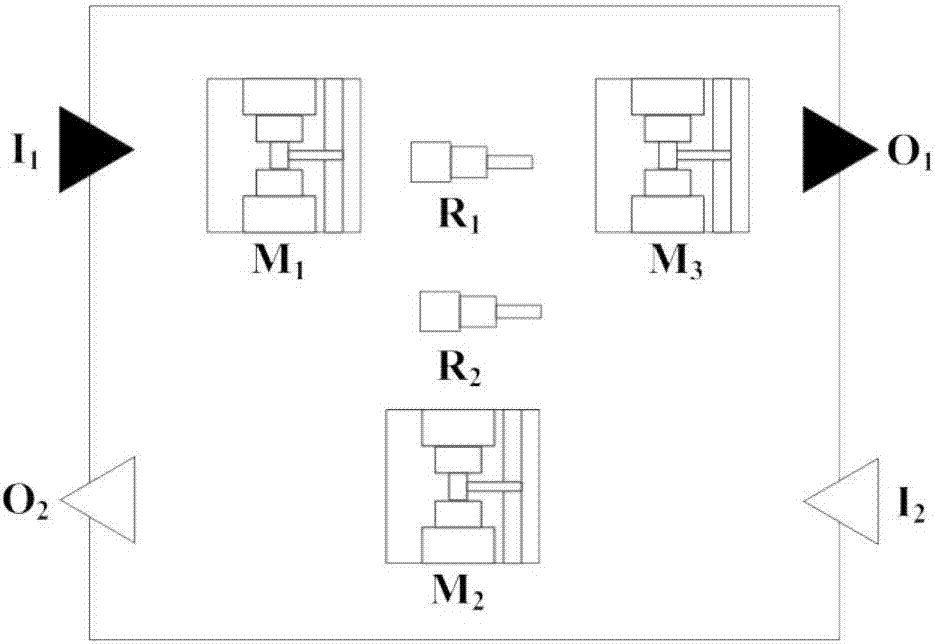

[0069] first step, figure 1 is a robot consisting of two robots (R 1 , R 2 : Each robot can hold one product at the same time) and three machines (M 1 , M 2 , M 3 : Each machine can process two products at the same time), and two input buffers (I 1 ,I 2 ) and two output buffers (O 1 ,O 2 ), an automated product production system composed together. The system is mainly divided into two production lines with two robots as the core, and its operation process is

[0070] J 1 : I 1 →R 1 → M 1 →R 2 → M 2 →O 1

[0071] or I 1 → M 3 →O 1

[0072] J 2 : I 2 → M 1 →R 2 → M 2 →O 2

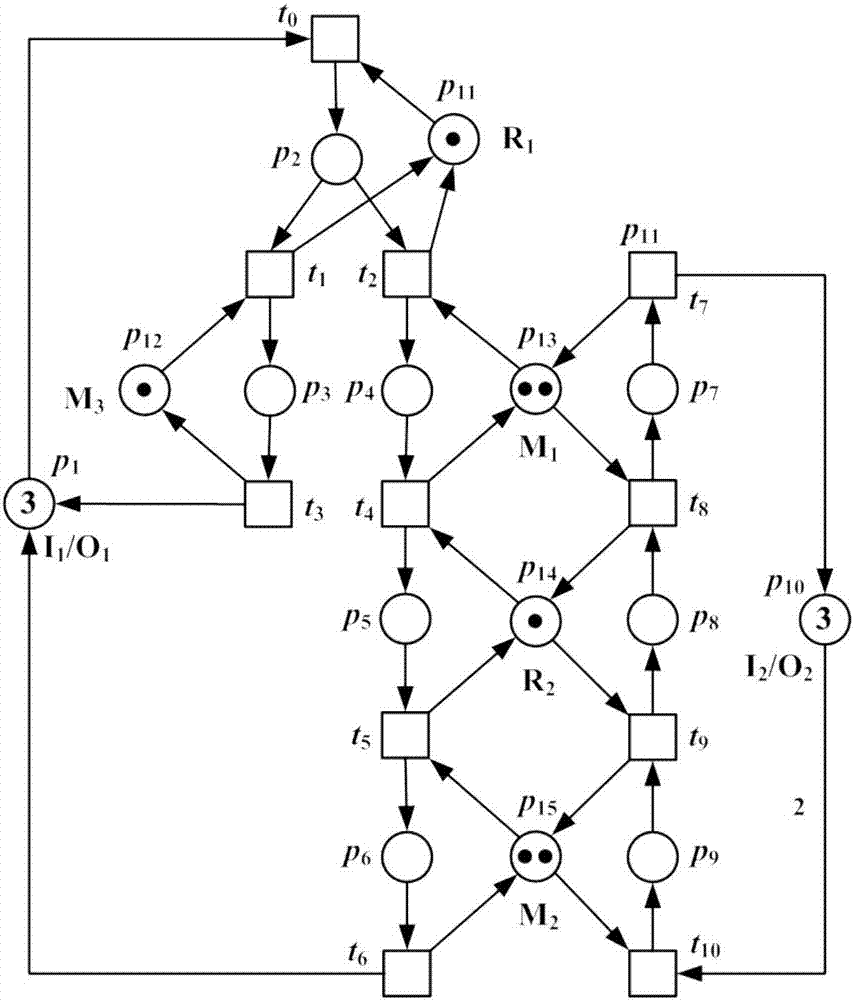

[0073] Using Petri net pairs figure 1 The workshop manufacturing system shown is modeled, and the obtained Petri net model is as follows figure 2 shown. figure 2 The shown Petri net model is an example net commonly used in Petri net related res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com