Rotor system typical fault diagnosis method based on current signal

A technology of current signals and typical faults, which is applied in the field of typical fault diagnosis of rotor systems based on current signals, can solve problems such as the influence of fault diagnosis results, signal annihilation, and many signal noise components, so as to achieve convenient implementation, overcome strong power frequency and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process.

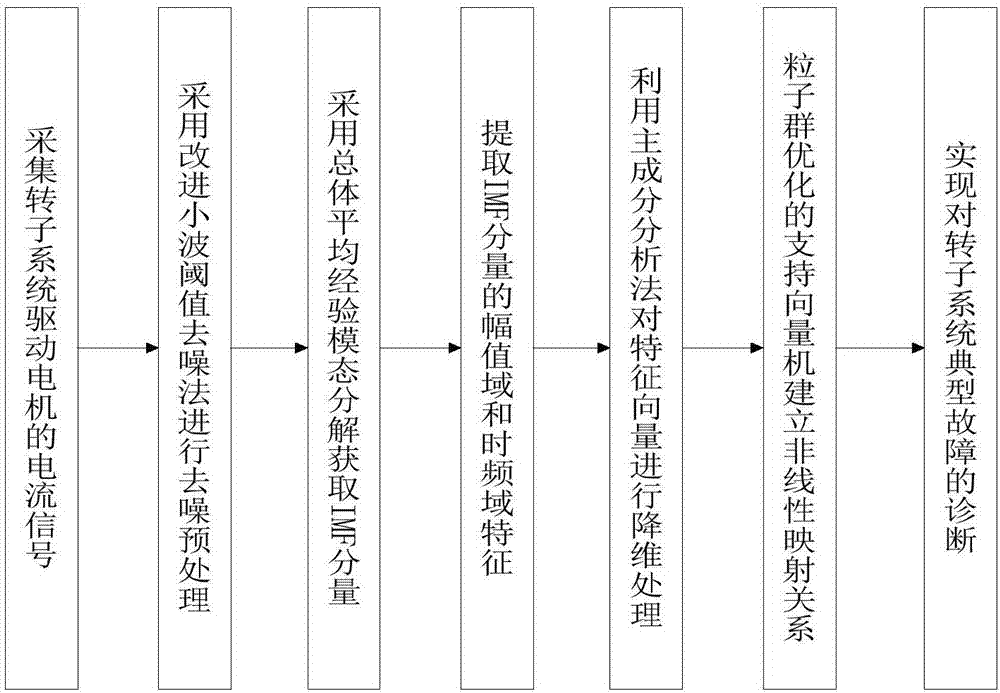

[0020] like figure 1 As shown, this embodiment includes the following steps:

[0021] 1. Collect the motor current signals under different faults of the rotor system. When the rotor system fails, it will cause torque fluctuations on the rotating shaft, and the torque fluctuations are fed back to the motor to cause changes in the motor current.

[0022] 2. In order to avoid the influence of the current change in the motor starting stage, the current signal when the motor rotates at a constant speed is collected as the time domain signal x(t) to be processed; Time interval, n represents the number of sampling points.

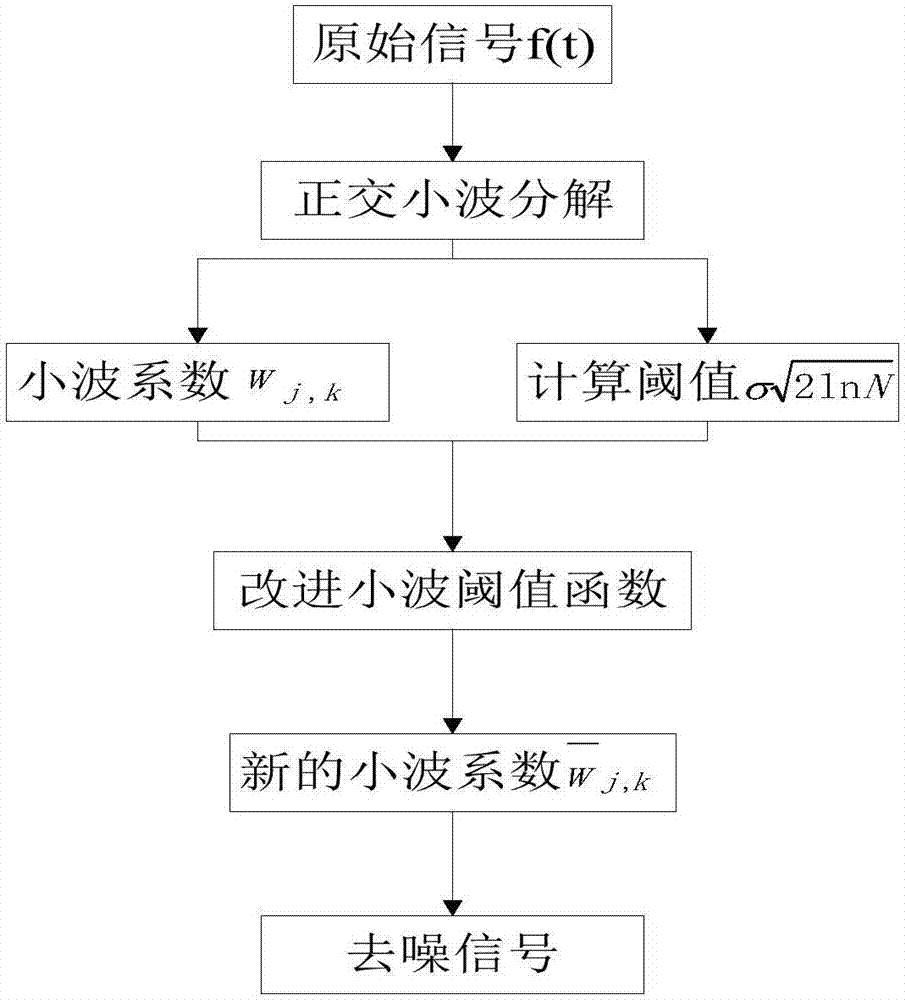

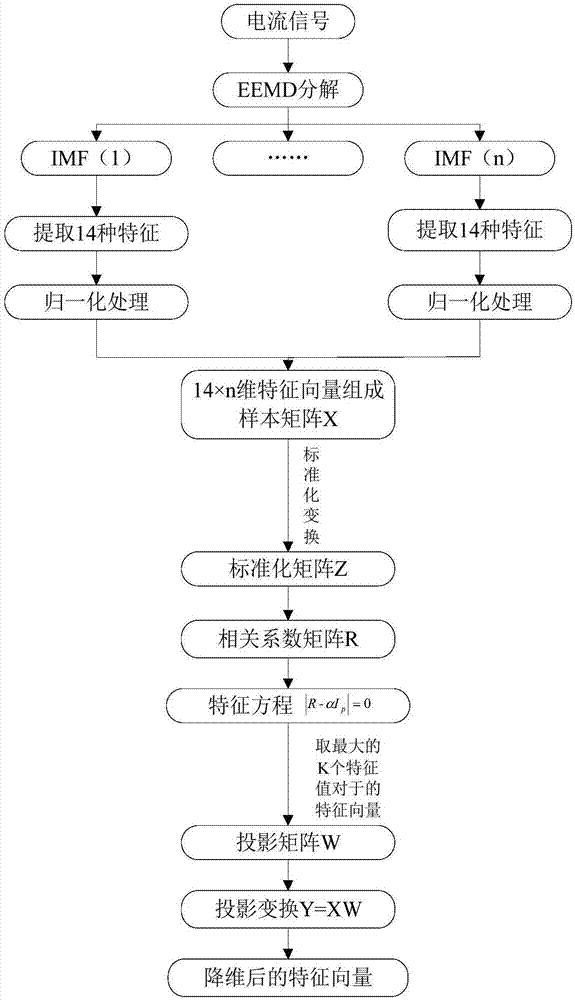

[0023] 3. Perform denoising preprocessing on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com