Transmission gear

A transmission gear and gear body technology, applied in the field of mechanical parts, can solve problems such as the influence of transmission efficiency and the breakage of convex teeth, and achieve the effects of unique shape, tight fit and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

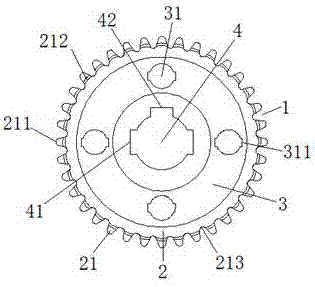

[0017] Such as figure 1 As shown, a transmission gear includes a gear body 1, the gear body 1 is composed of a tooth seat 2 and a tooth surface 3, and the tooth seat 2 is provided with a plurality of arc-shaped convex teeth 21, and the arc-shaped convex teeth 21 The top end is provided with an arc tooth top 211, and an arc groove 213 is arranged between two of the arc convex teeth 21, and four thread fixing holes 31 are symmetrically arranged on the tooth surface 3, and the center of the tooth surface 3 A fixed hole ring 4 is arranged at the position, and a boss 42 is arranged on the fixed hole ring 4 .

[0018] The root of the arc-shaped convex tooth 21 is provided with a reinforcing rib 212, and the reinforcing rib 212 is provided on both sides of the tooth root of the arc-shaped convex tooth 21, and the length of the reinforcing rib 212 is the same as that of the arc-shaped convex tooth 21 teeth. The length of the root is corresponding, and the reinforcing rib 212 realizes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com