3D printer

A technology of 3D printer and printing platform, applied in the field of 3D printing, can solve the problems of inability to eliminate noise and increase machine noise, and achieve the effect of reducing weight, reducing noise and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

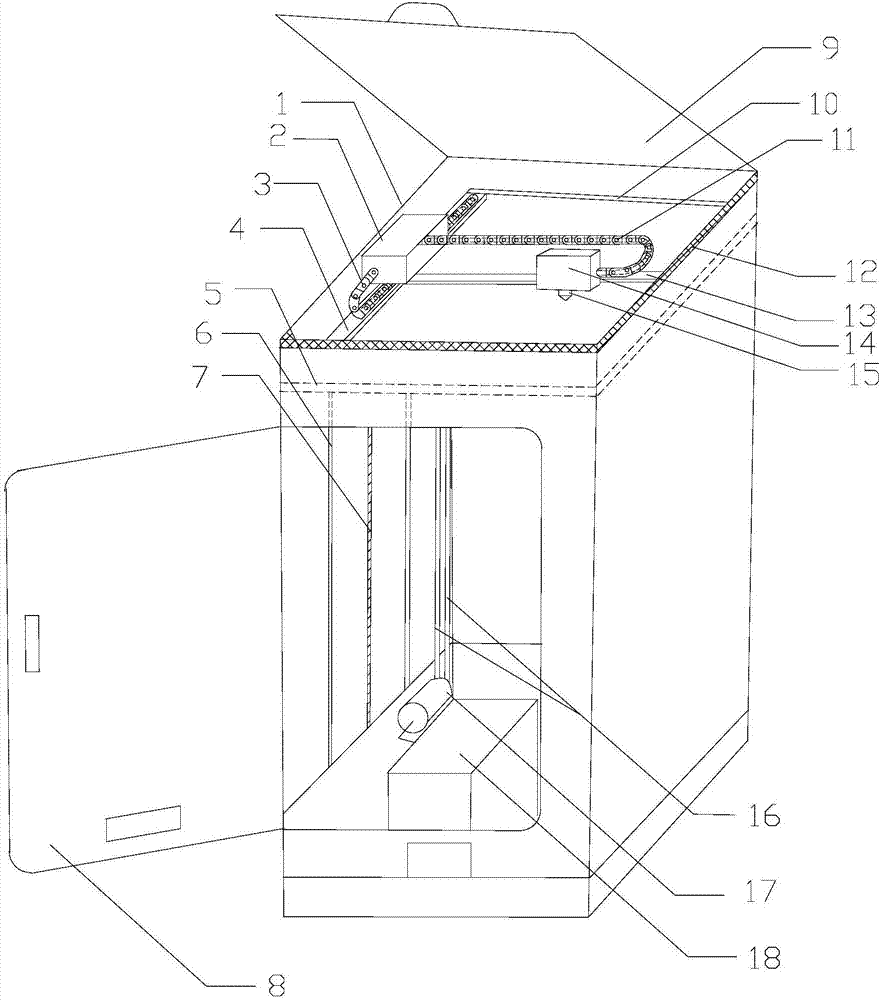

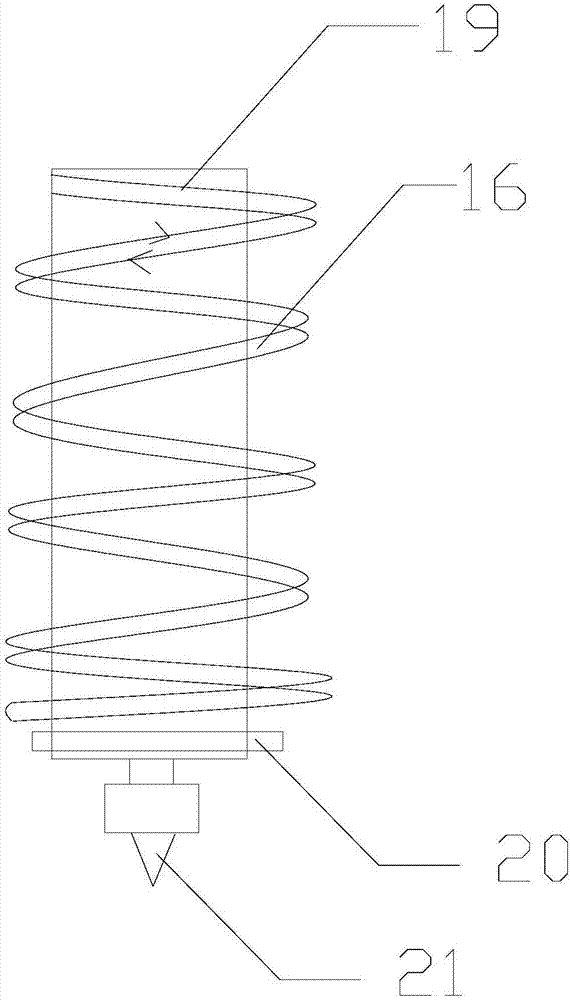

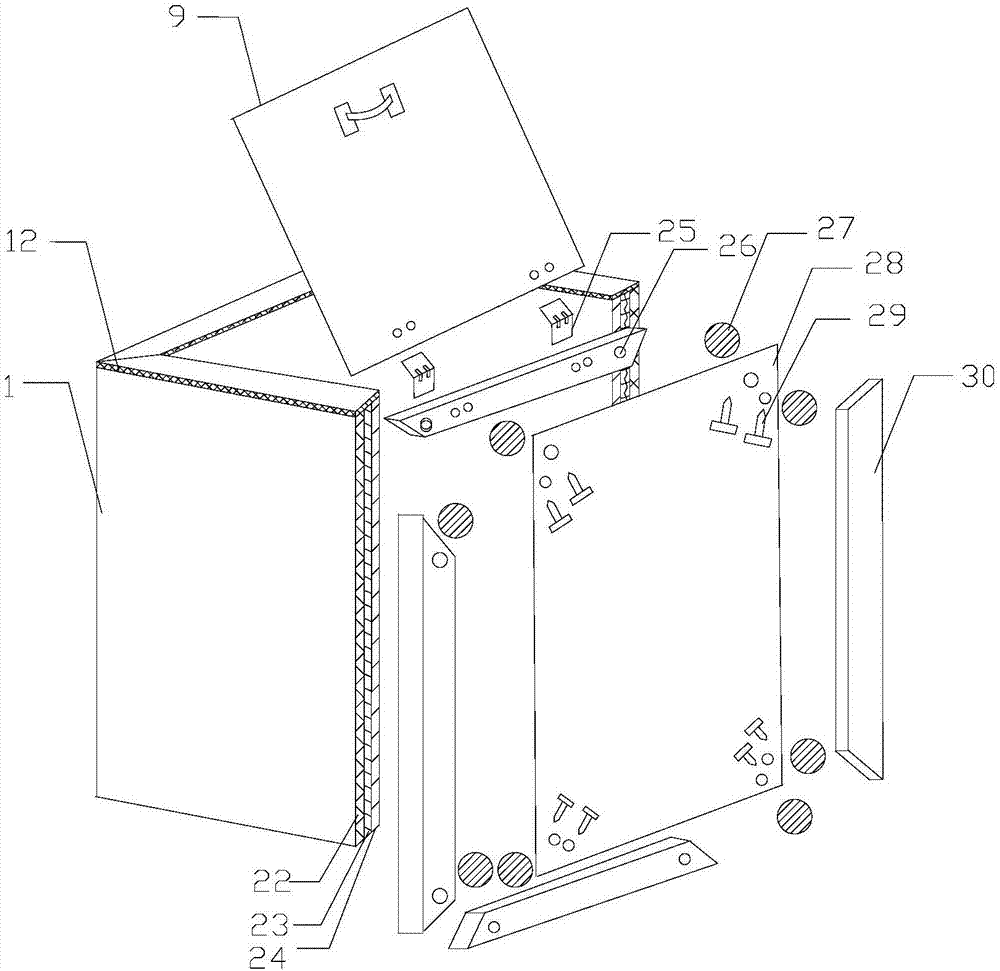

[0024] A 3D printer, comprising: a casing 1, an operating platform and a printing platform 5, wherein: the casing 1 is a cuboid structure, and the materials of the front panel, the left panel and the right panel of the casing 1 are the same, and each includes three Layer structure, from the outside to the inside layer is a protective shell 22, a resonant sound-absorbing layer 23 and a sound-absorbing layer 24, the front panel, the left panel and the upper edge of the right panel are fixed with matching strip rubber pads 12, so The rear panel 28 is fixed at the back of the housing 1, the keel 30 is fixed by screws 29 around the rear panel 28 in contact with the housing 1, and the rear panel 28 and the keel 30 are fixed by screws 29. A circular rubber pad 27 is provided. The upper edge of the rear panel 28 is fixed by a hinge 25 to match the upper cover 9 of the housing 1; the upper part of the housing 1 is provided with an operating platform, and the operating platform includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com