A Control Method for Improving Roll Gap Precision of Continuous Caster

A control method, technology of continuous casting machine, applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

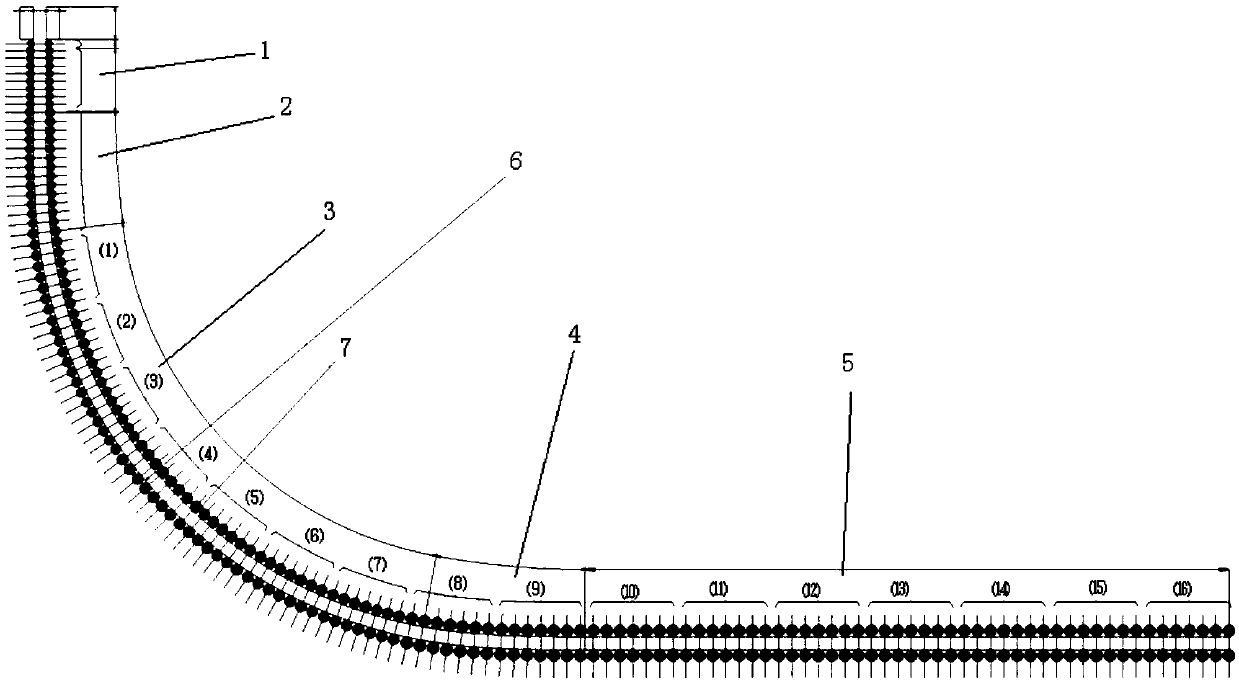

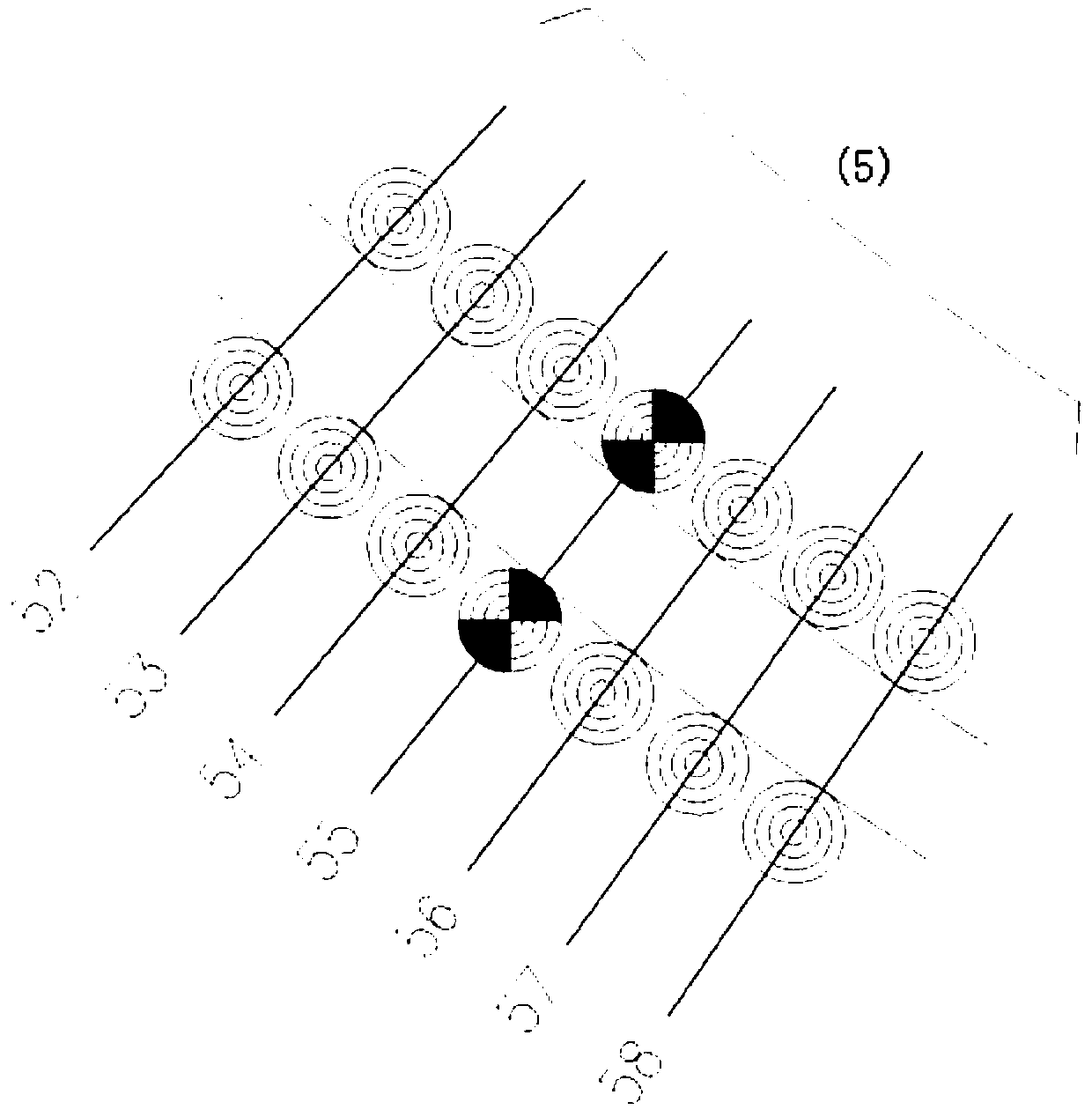

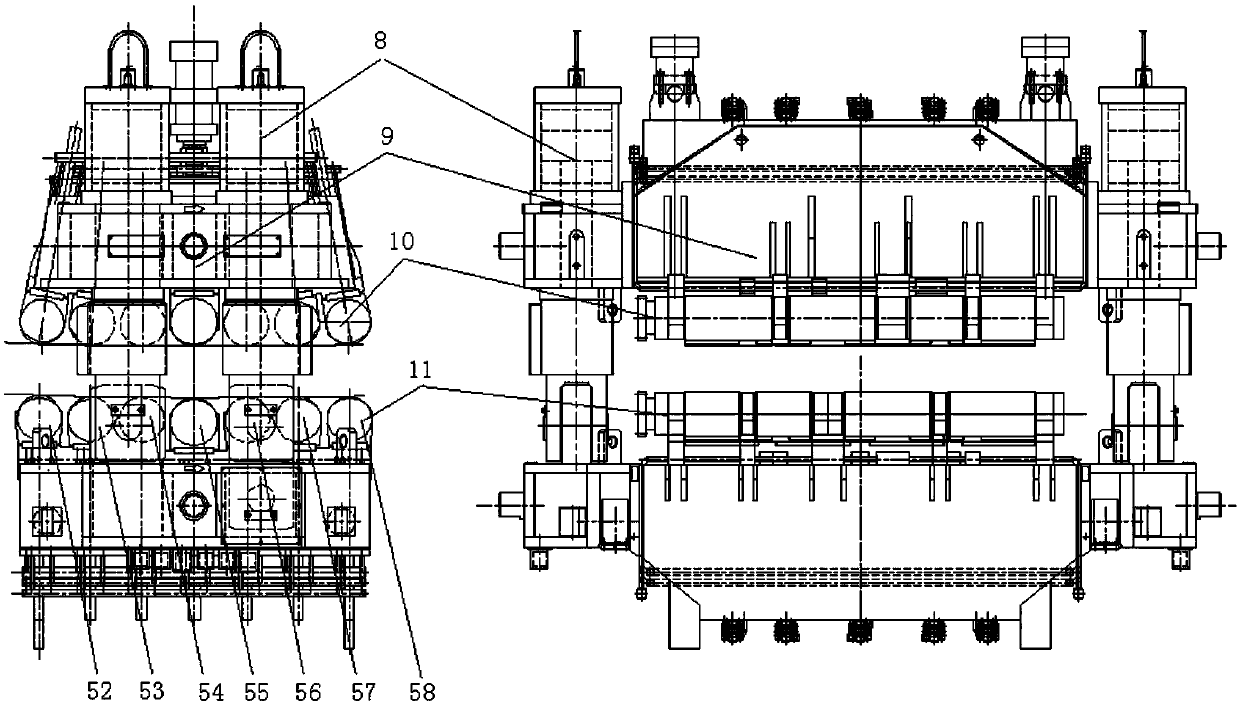

[0030] In the embodiment of the present invention, first calculate the roll gap compensation amount of the control reference position of each segment of the arc segment and the straightening segment (that is, the first and last rollers of the segment), and take the roll gap of the horizontal segment The compensation amount β=0; after calculating the roll gap compensation amount β of each segment, the existing roll gap setting value is compensated to obtain the final roll gap setting value.

[0031] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0032] This patent applies to all slab con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com