Rolling method for strip steel

A technology of strip steel and finish rolling, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of reducing the yield of finished strip steel products, increasing the weight of cutting heads and tails, and increasing production costs, etc., to achieve reduction Yield, reduce the weight of cutting head and tail, and increase the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

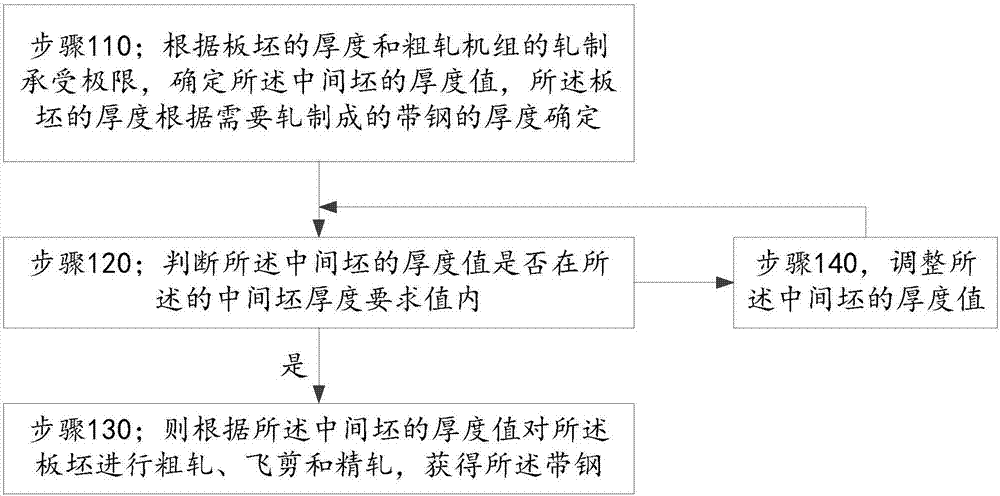

[0039] Example 1: the rolling method of the strip steel comprises the steps:

[0040] Step S1: The specification of the strip steel is 2.85*1250mm, the thickness of the slab is determined according to the specification of the strip steel, and the thickness of the SPHC intermediate slab with a weight of 25t is determined according to the thickness of the slab and the rolling tolerance limit of the finishing and roughing mill The value is 32mm;

[0041] Step S2: The thickness of the intermediate billet is 32 mm. In the secondary control, the thickness of the intermediate billet is changed from 38 mm (the thickness of the original intermediate billet) to 32 mm.

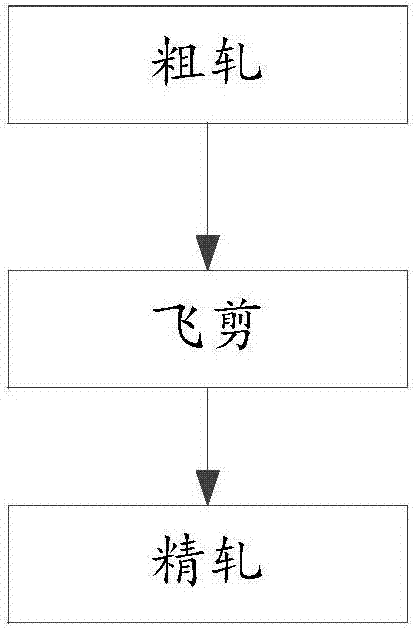

[0042] Step S3: Perform rough rolling, flying shearing and finish rolling on the slab according to the thickness value of the intermediate slab to obtain the strip steel, and increase the steel throwing speed in the finish rolling process, and The steel throwing speed is increased by 0-1m / s, and the temperature drop at ...

example 2

[0049] Example 2: the rolling method of described steel strip comprises the steps:

[0050] Step S1: The specification of the strip steel is 3.5*1800mm, the thickness of the slab is determined according to the specification of the strip steel, and the thickness value of the H220YD intermediate slab is determined to be 31mm according to the thickness of the slab and the rolling tolerance limit of the roughing mill ;

[0051]Step S2: The thickness of the intermediate billet is 31mm. The required thickness of the intermediate billet is within the range of 29mm-60mm. In the secondary control, the thickness of the intermediate billet is changed from 34mm (the thickness of the original intermediate billet) to 31mm.

[0052] Step S3: Perform rough rolling, flying shearing and finish rolling on the slab according to the thickness value of the intermediate slab to obtain the strip steel, and increase the steel throwing speed in the finish rolling process, and The steel throwing speed ...

example 3

[0054] Example 3: the rolling method of the strip steel comprises the steps:

[0055] Step S1: The specification of the strip steel is 2.0*1250mm, the thickness of the slab is determined according to the specification of the strip steel, and the thickness value of the 380CL intermediate slab with a weight of 22t is determined according to the thickness of the slab and the rolling tolerance limit of the roughing mill 33mm;

[0056] Step S2: The thickness of the intermediate billet is 33mm. The required thickness of the intermediate billet is within the range of 29mm-60mm. In the secondary control, the thickness of the intermediate billet is changed from 35mm (the thickness of the original intermediate billet) to 35mm.

[0057] Step S3: Perform rough rolling, flying shearing and finish rolling on the slab according to the thickness value of the intermediate slab to obtain the strip steel, and increase the steel throwing speed in the finish rolling process, and The steel throwin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com