Rainfall titration tester and rainfall titration test method

A test method and tester technology, applied in the direction of rainfall/precipitation gauges, instruments, measuring devices, etc., can solve the problems of non-standard error evaluation, inaccurate precipitation collection, and difficult control of water injection titration speed, so as to improve the accuracy of collection The effect of improving the accuracy of flood control early warning and forecasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

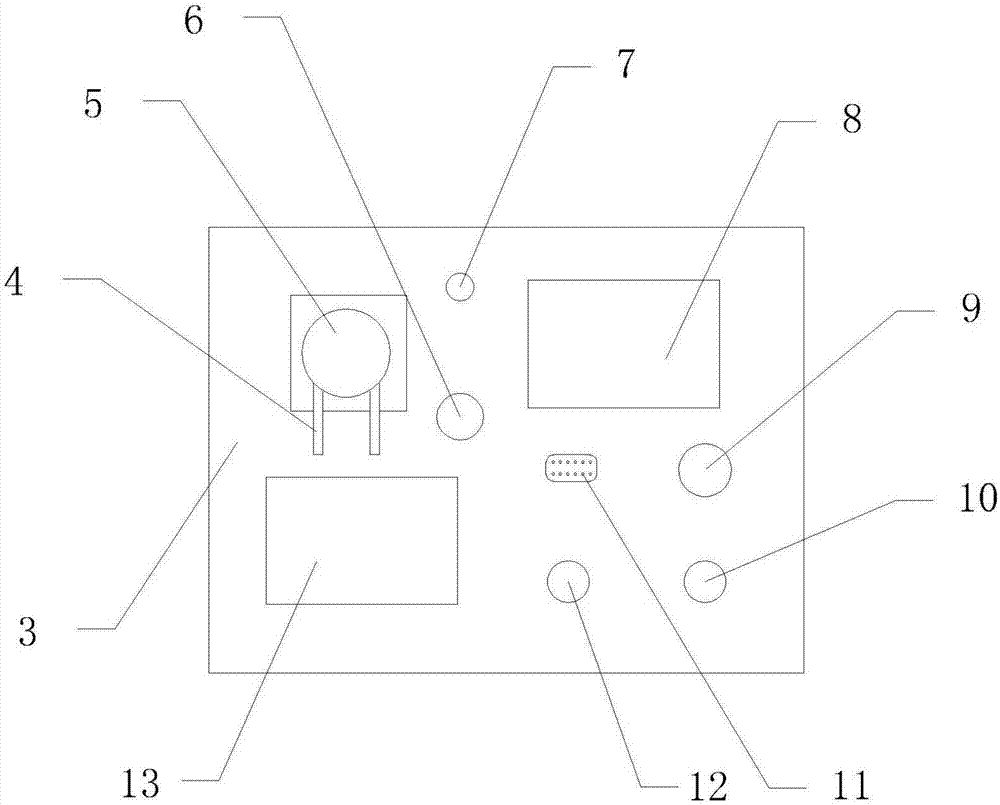

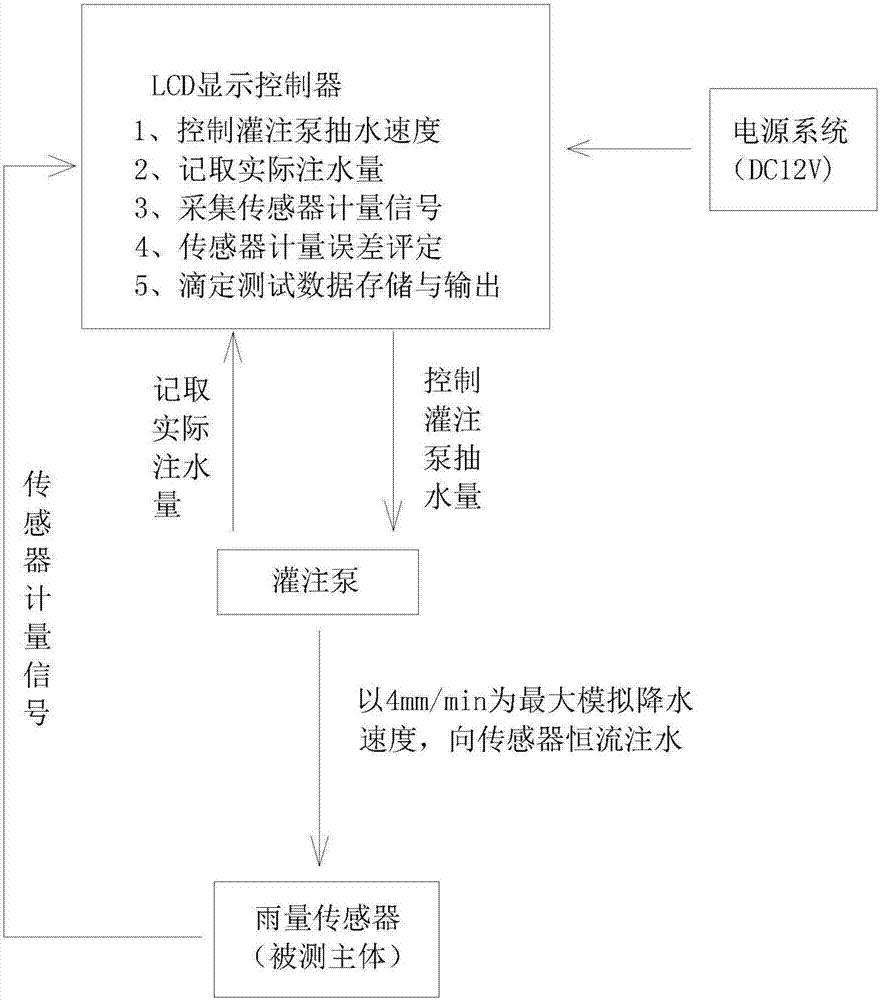

[0029] Such as figure 1 , 2 As shown in and 3, the rainfall titration tester includes an ABS material chassis 1 and a case cover 2, a single-chip microcomputer and a memory are arranged in the chassis 1, an aluminum alloy material panel 3 is provided on the chassis 1, and a water injection metering unit, a display panel 3 is provided on the panel 3 Control unit, power supply unit. The single chip microcomputer is connected with the memory, the water injection metering unit, the display control unit and the power supply unit.

[0030] The water injection metering unit includes a perfusion pump, a water storage tank 13 and some water pipes; wherein the perfusion pump is a metering peristaltic pump 5, the metering peristaltic pump 5 is connected with a peristaltic pipe 4, and the water pipe is a silicone water pipe;

[0031] Filling pump, used for metering and pumping water, with an accuracy of 0.01 ml;

[0032] The water storage tank 13 is used for preloading simulated rainfa...

Embodiment 2

[0051] Rain titration test method, including the following steps:

[0052] A0, start the machine, open the switch 9 of the rain titration tester described in embodiment 1, and turn on the power.

[0053] A01, setting parameters,

[0054] Parameter settings include basic parameter settings and working condition parameter settings:

[0055] Basic parameters include:

[0056] Station No.: the station No. of the station under test, usually a water code consisting of 10 digits or letters;

[0057]Test serial number: the count of the number of tests at the same station, which can be recorded from 1 or the existing serial number;

[0058] Rain gauge type: including pulse type, serial port type, etc.;

[0059] Pulse signal type: The measured rain gauge is connected to pulse or complementary pulse (one on and one off);

[0060] Rain gauge resolution: the rainfall corresponding to each pulse of the measured rain gauge (0.1, 0.2, 0.5, 1.0mm);

[0061] Titration mode: including timi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com