Check valve special for gas pipeline

A technology for gas pipelines and check valves, which is applied in the direction of lift valves, valve details, control valves, etc., can solve problems such as blockage and check function failure, and achieve the effects of improving safety performance, preventing gas backflow, and ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

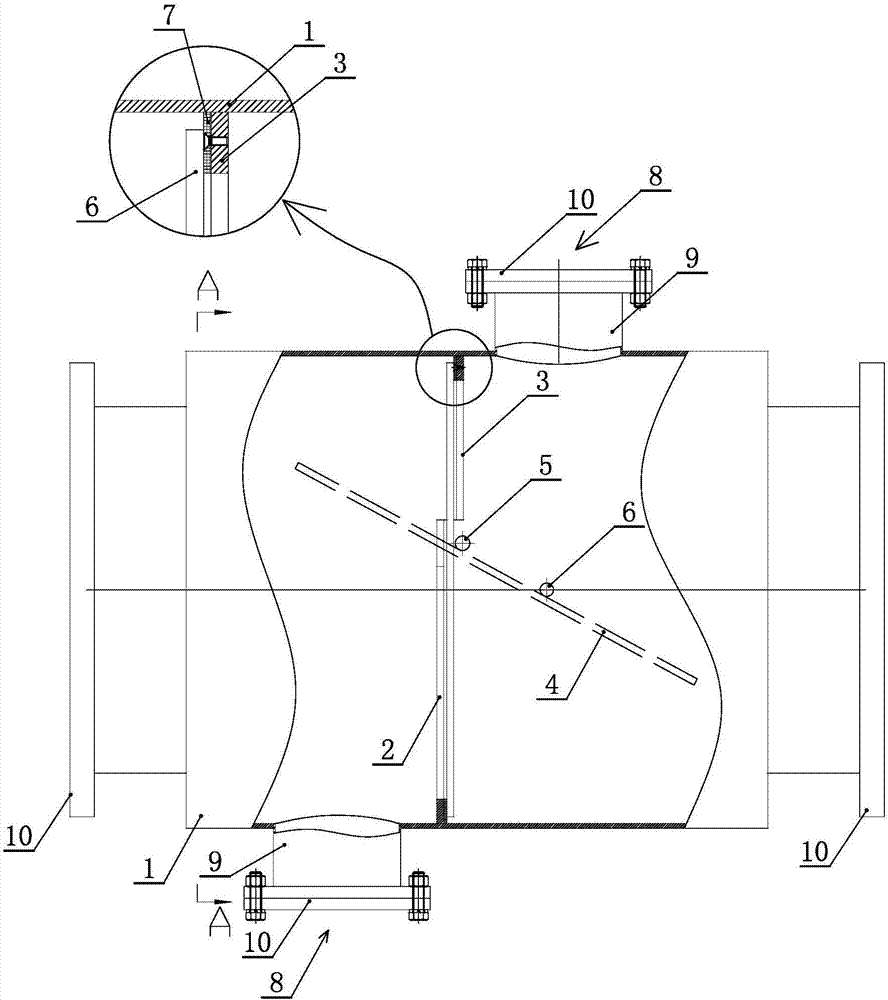

[0023] The following is attached Figure 1-4 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

[0024] Such as figure 1 , figure 2 As shown, the pipe body 1 of the gas pipeline is fixed with a semicircular first sealing ring plate 2 and a second sealing ring plate 3 corresponding to the inner wall of the pipe body 1 . The first sealing ring plate 2 and the second sealing ring plate 3 are arranged staggeredly along the axial direction of the pipe body 1, so as to figure 1 For example, the first sealing ring plate 2 is located on the left, and the second sealing ring plate 3 is located on the right. And the arc surface of the first sealing ring plate 2 is tightly fitted and fixed on the inner wall of the pipe body 1. There is a gap at the top of the first sealing ring plate 2 to facilitate the turning of the valve pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com