Ceramic tap

A technology of ceramics and faucets, which is applied in the field of sanitary ware, can solve the problems of complicated process, time-consuming and laborious, inconvenient installation and maintenance, etc., and achieve the effect of simple installation steps, reduced costs and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below through specific embodiments.

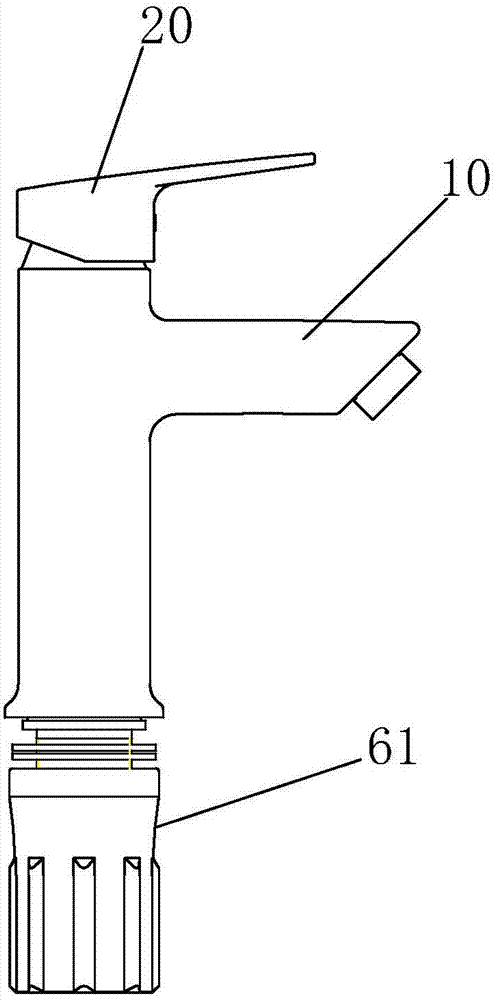

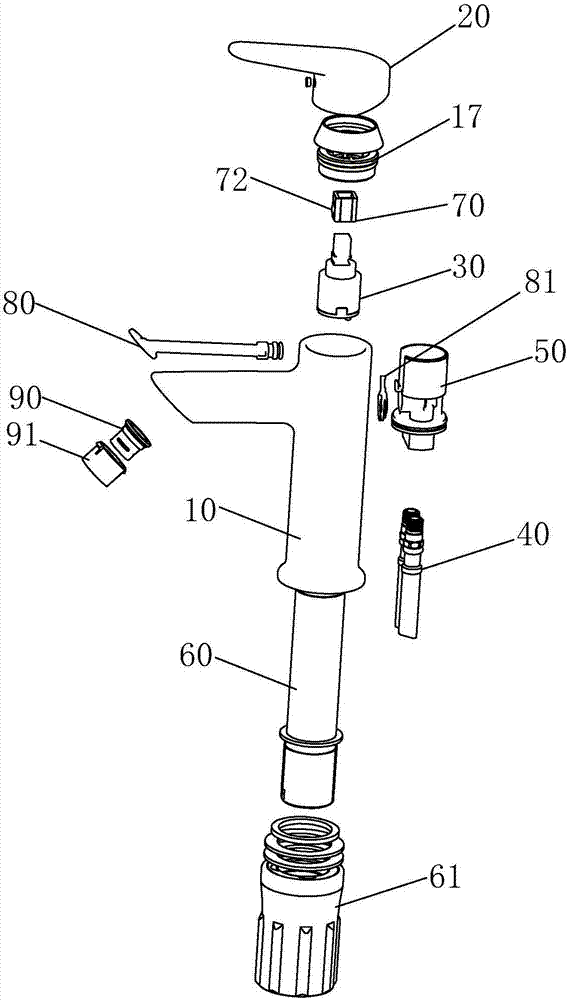

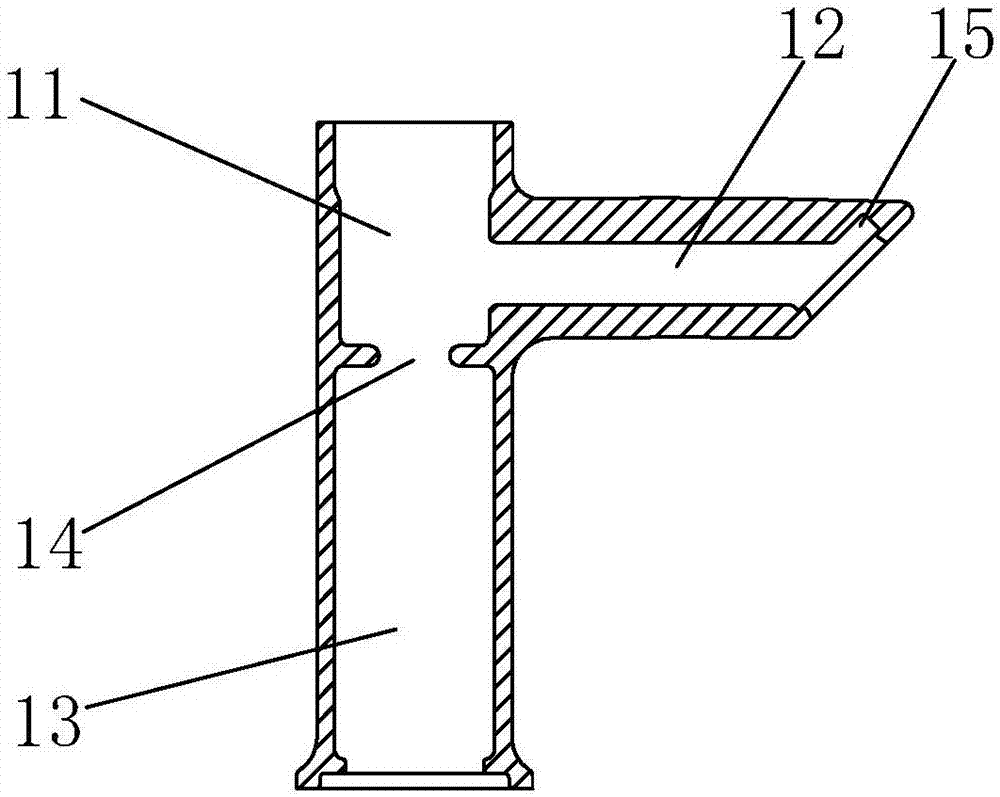

[0037] refer to Figure 1 to Figure 14 , a ceramic faucet, comprising a ceramic handle 20, a ceramic valve body 10, a valve core 30, a water inlet pipe 40, a valve core seat 50, a fixed pipe 60, a fixed sleeve 70, a water outlet pipe 80, an elastic buckle 81, and a bubbler 90 Wait. The ceramic valve body 10 is provided with a first accommodating cavity 11 , a second accommodating cavity 12 and a third accommodating cavity 13 . The first accommodating cavity 11 and the second accommodating cavity 12 are arranged at a certain angle and communicate with each other. . The third accommodating cavity 13 is located below the second accommodating cavity 12 , and a through hole 14 is provided between the third accommodating cavity 13 and the second accommodating cavity 12 .

[0038] The valve core seat 50 is provided with a water inlet 51 , a water outlet 52 and a cavity 53 , and the cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com