Bathroom inverse bank one-time forming template supporting method

A technology for forming formwork and toilets, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve problems such as increasing construction difficulty, achieve good promotion value, speed up construction progress, and save measures cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

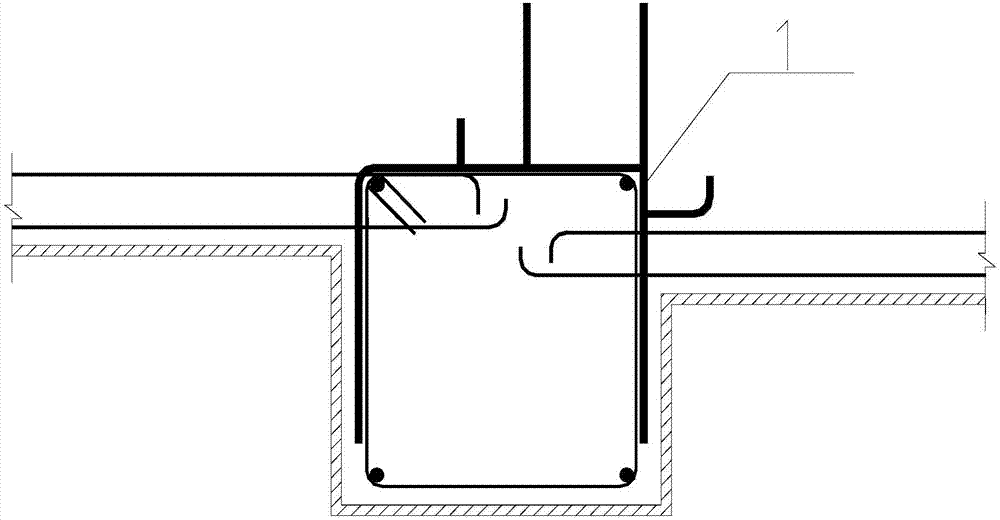

[0015] Figure 1 to Figure 6 It is a specific embodiment of the patent of the present invention. Below in conjunction with accompanying drawing, the patent of the present invention is further described.

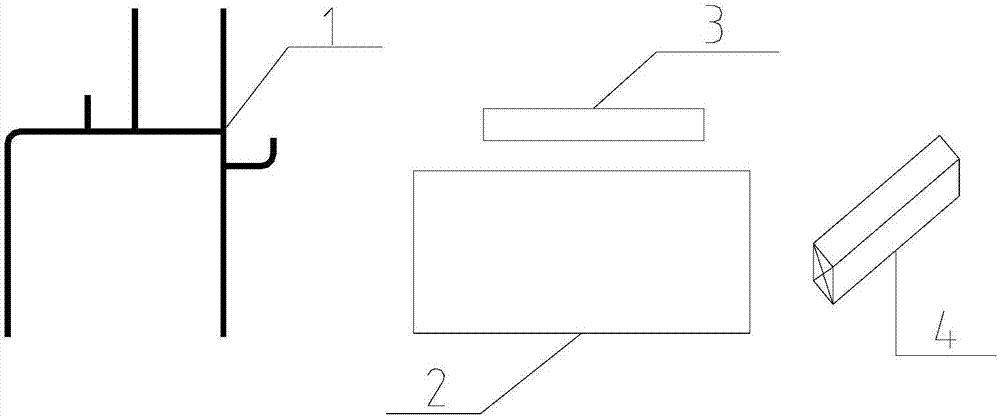

[0016] figure 1 For the first step of construction, the materials used in this method. The support frame 1 is made of steel bars, the lower steel bars of the frame are parallel, and the opening size is slightly larger than the distance between the main bars of the concrete beam. The upper reinforcement is parallel, and the opening size is equal to the width of the reverse sill minus the thickness of the reinforcement cover. During construction, after the binding of beam reinforcement and slab reinforcement is completed, the supporting frame is bound to the main reinforcement and stirrup of the beam for reinforcement, and then the formwork is supported and concrete is poured.

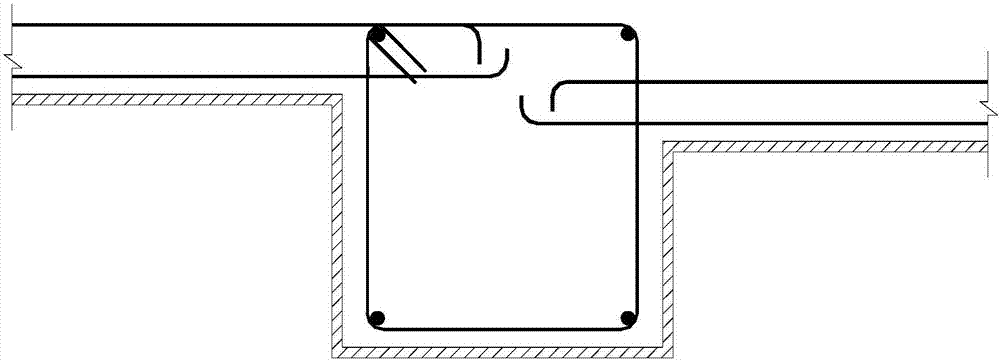

[0017] figure 2 For the second step of construction, the binding construction of beams and sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com