Outward extending end plate joint

An end plate and node technology, applied in the field of outrigger end plate nodes, can solve the problems of insufficient consideration of regional ductility, deformation capacity and safety reserve, lack of secondary protection ability, inconsistent seismic design principles, etc., to ensure safety. and integrity, increased ductility, high production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

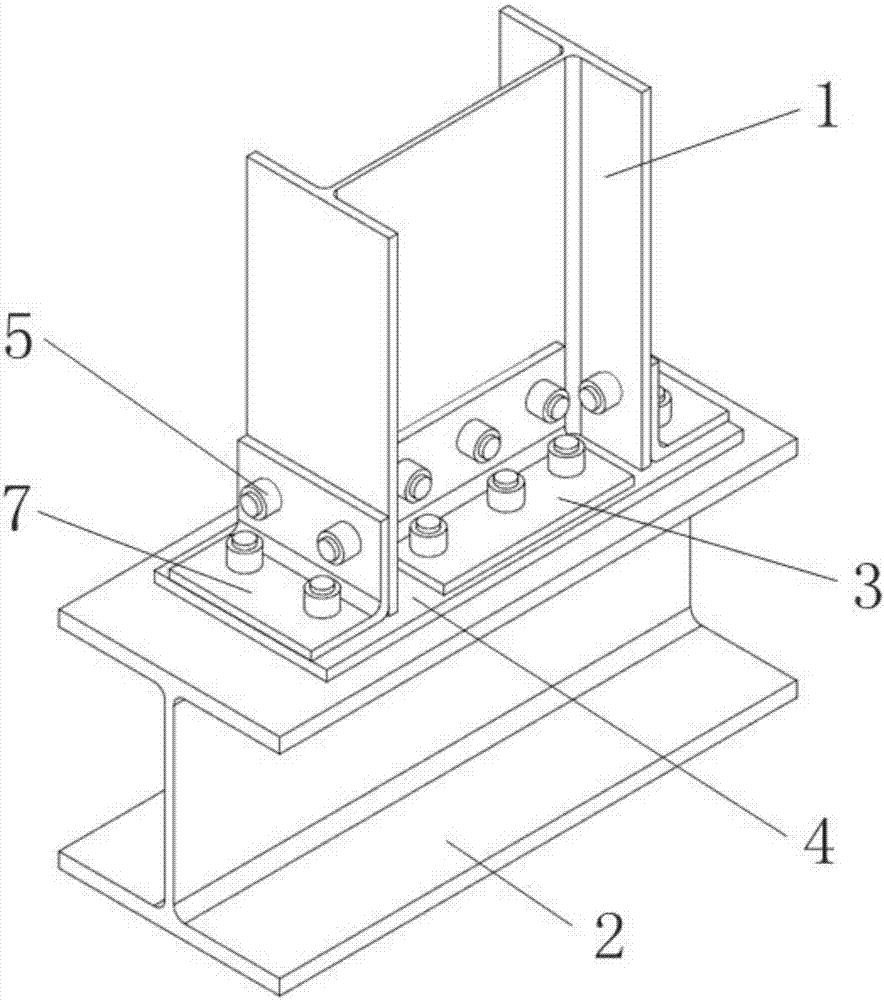

[0022] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] As shown in the figure, the extended end plate node in the present invention includes steel beam 1, steel column 2, angle steel, end plate 4 and bolt 5, the steel beam 1 is an I-shaped steel beam, and the steel column 2 is an H-shaped steel column, the end plate 4 is welded on the end of the steel beam 1, the end plate 4 is an extended end plate, the angle steel includes an L-shaped angle steel 3 and a top and bottom angle steel 7, and the L-shaped angle steel 3. The top and bottom angle steels 7 and the bolts 5 are made of stainless steel; the steel beam 1 web and flange, the end plate 4, the steel column 2 flange and the angle steel are correspondingly provided with bolt holes 6 for passing through the bolts. The L-shaped angle steel 3 is arranged between the web plate of the steel beam 1 and the end plate 4, and the L-shaped angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com