ld pin automatic closing device

An automatic technology for pins, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as defective products, gold and tin damage, time-consuming and labor-intensive problems, and achieve exquisite design, high reliability, and no impact on output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

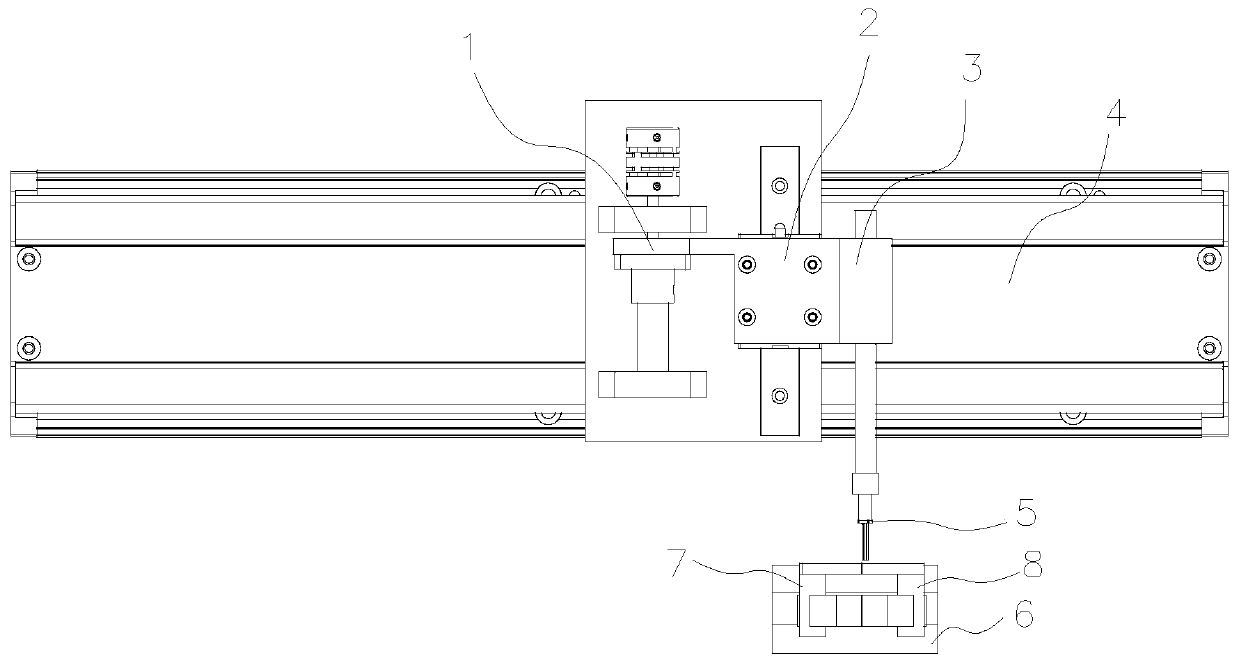

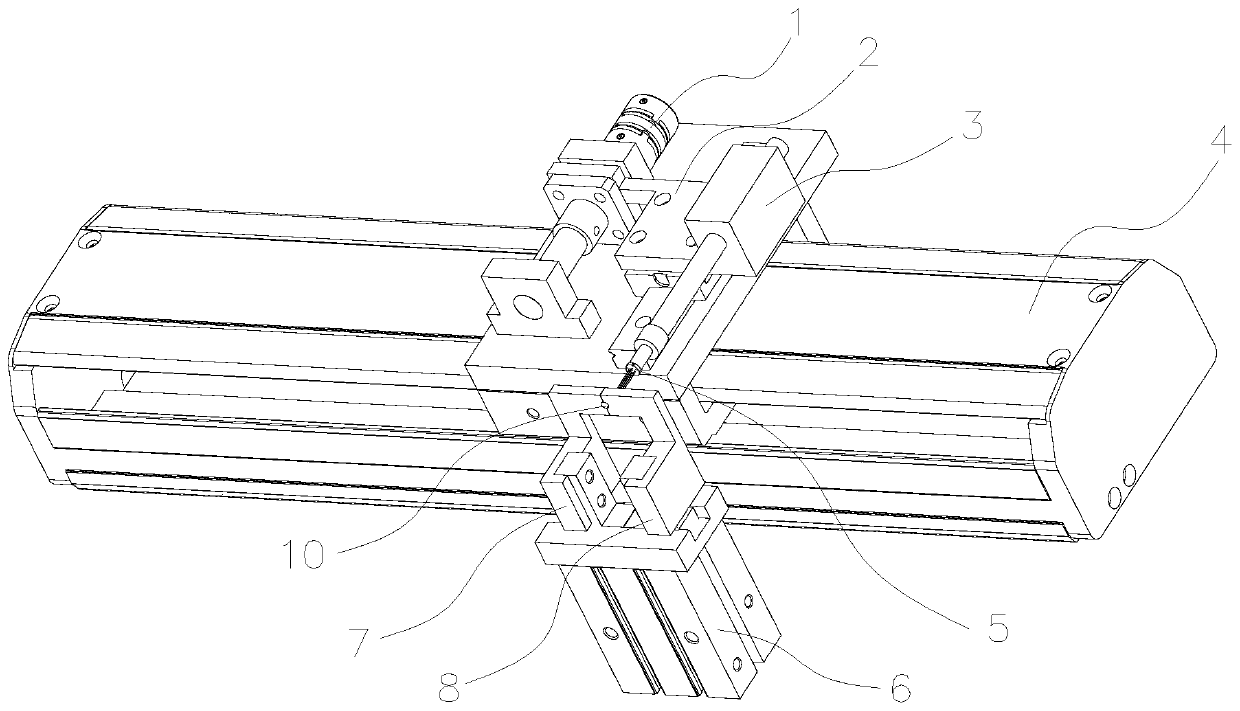

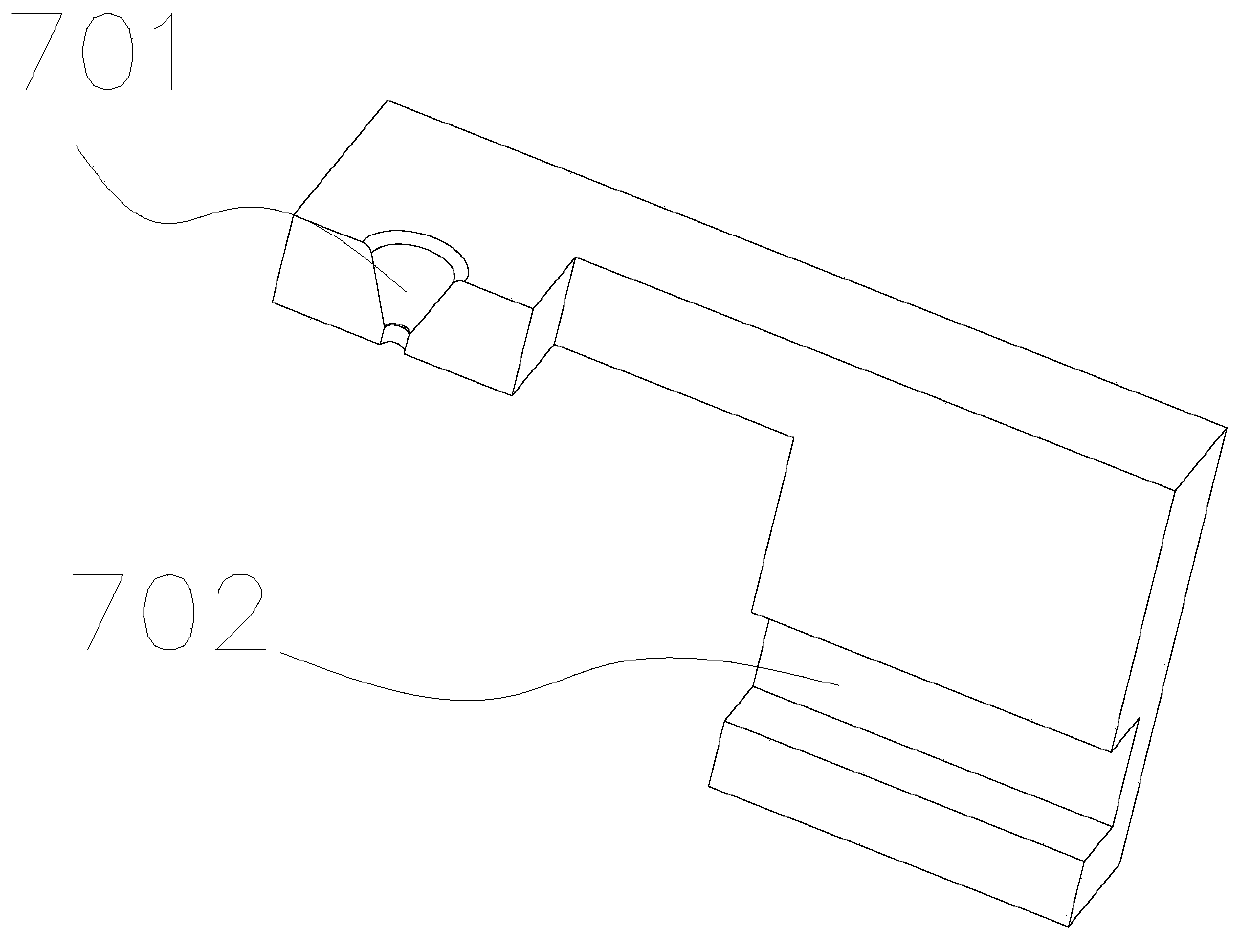

[0019] An LD pin automatic closing device, refer to figure 1 , including a closing clip arranged on the top of the copper electrode (not shown in the figure), the closing clip includes a left clip 7 and a right clip 8 driven by a pneumatic claw 6 to close or open, and the closing clip is provided with a The upper part is a cone-shaped through-hole 10, and the lower part is a cylindrical through-hole 10. The through-hole 10 is composed of the half-hole 701 on the left clip and the half-hole 801 on the right clip, which are respectively oppositely arranged, and are combined under the drive of the pneumatic claw 6. There is a Z-axis drive module 1 above the clip, and the Z-axis drive module 1 drives the suction nozzle module 3 connected to it to move up and down. The nozzle module 3 is vertically adsorbed with the tube base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com