A pm2.5 reunion device

A technology for processing chambers and dust particles, which is applied in the direction of electrostatic effect separation, solid separation, and dispersed particle separation, etc., can solve the problems of low dust removal efficiency of electrostatic precipitators, achieve the effects of increasing agglomeration effect, good separation effect, and improved agglomeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

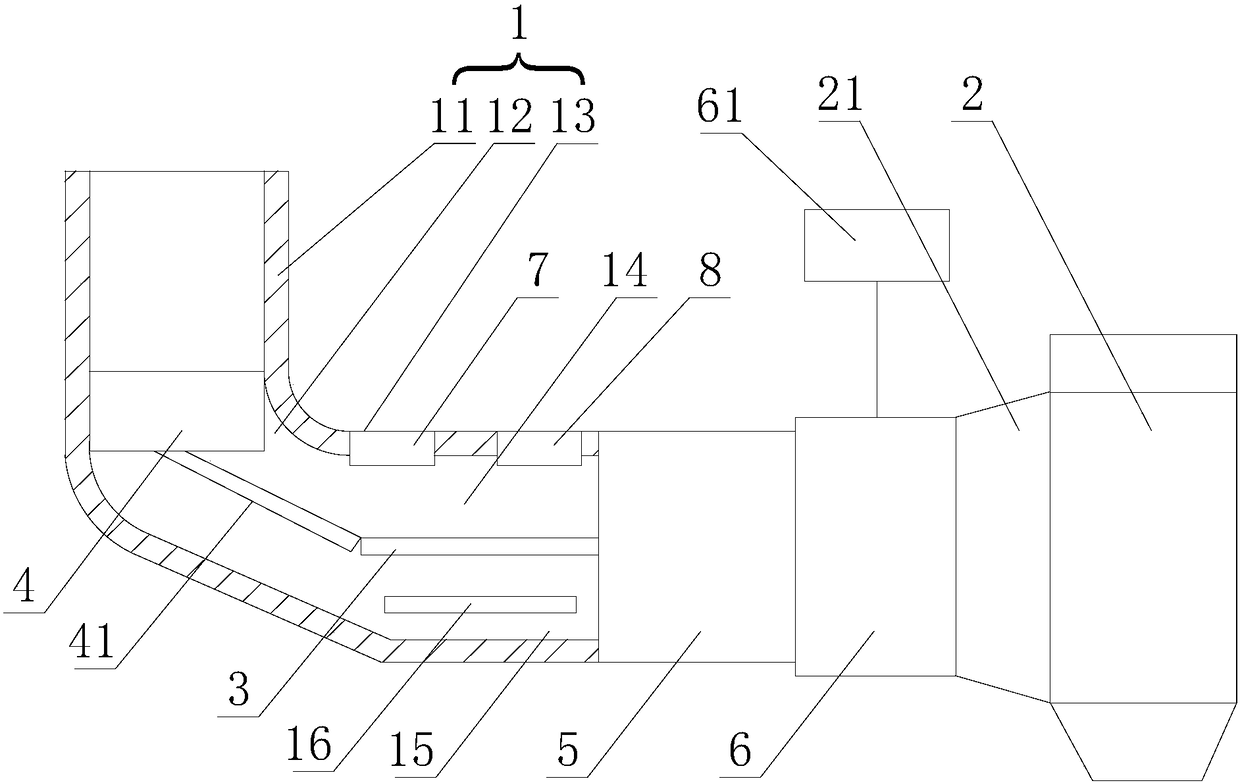

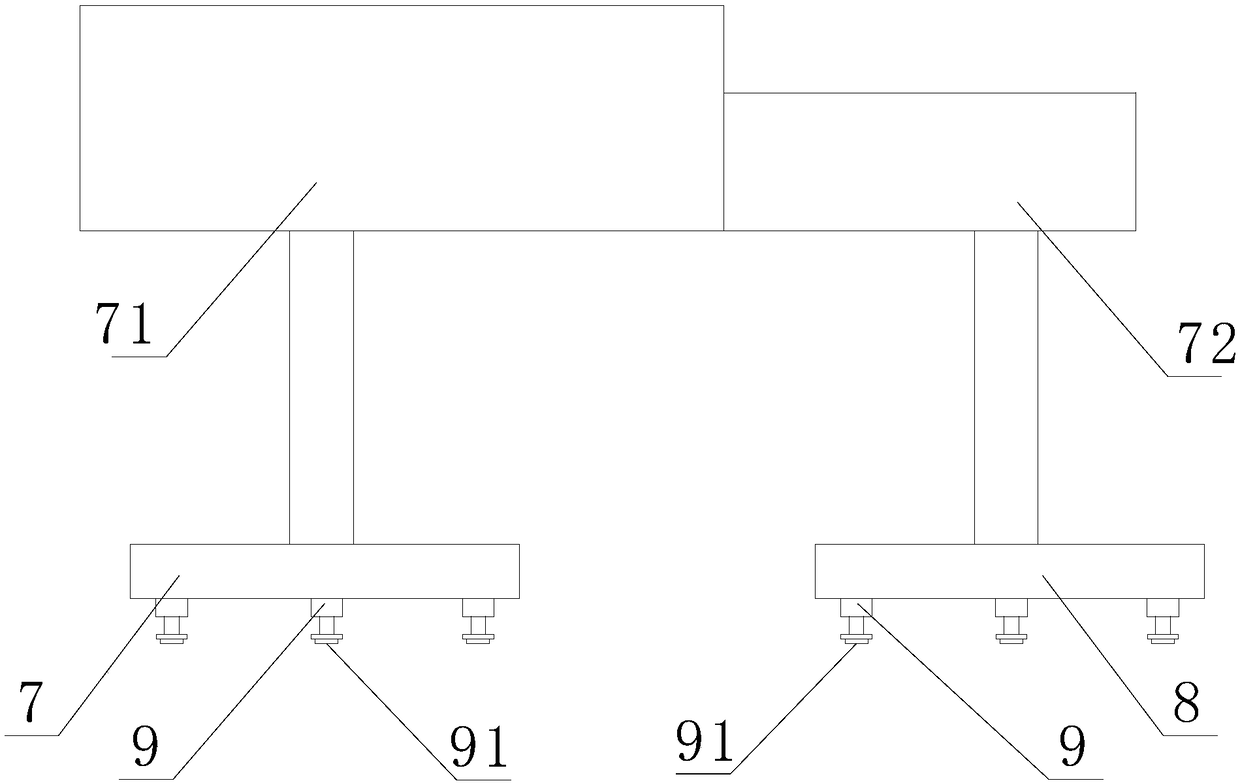

[0018] Such as figure 1 , figure 2 As shown, a PM2.5 agglomeration device includes a flue 1 and an electrostatic precipitator 2. The flue 1 includes a vertical section 11, an elbow section 12 and a horizontal section 13, and the elbow section 12 is arranged between the vertical section 11 and the horizontal section 13. Between the horizontal sections 13, an intermediate isolation layer 3 is arranged in the horizontal section 13 near one end of the elbow section 12, and the intermediate isolation layer 3 divides the horizontal section 13 into the first processing chamber 14 for fine dust particle processing and the first processing chamber 14 for coarse dust particle processing. The second processing chamber 15, and the first processing chamber 14 is arranged above the second processing chamber 15, the elbow section 12 is provided with a separator 4, and the coarse dust particles and fine dust particles in the flue 1 are automatically separated by inertia force. Separation, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com