Systems and methods for internal surface conditioning assessment in plasma processing equipment

A plasma and processing system technology, applied in the field of plasma processing equipment, can solve the problem of destroying the stability of plasma processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

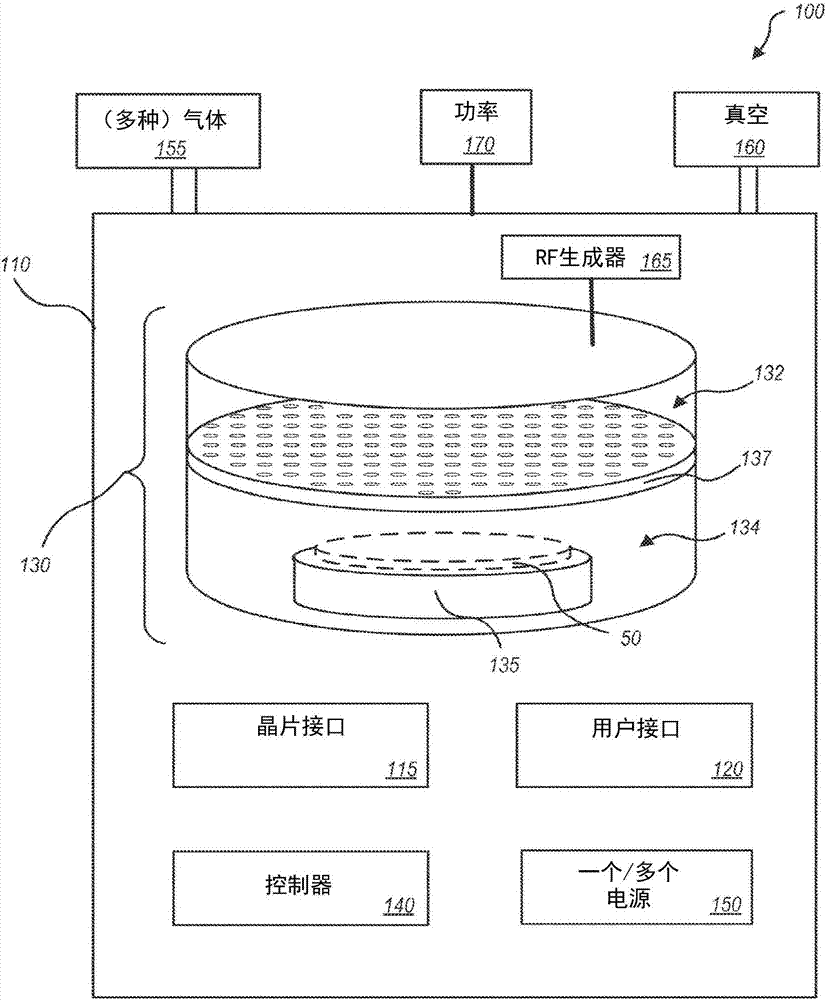

[0027] figure 1The main elements of a plasma processing system 100 according to an embodiment are schematically illustrated. System 100 is depicted as a single wafer, semiconductor wafer plasma processing system, but it will be apparent to those skilled in the art that the techniques and principles herein are applicable to any type of plasma generation system (e.g., not necessarily processing wafers or semiconductor systems). Processing system 100 includes housing 110 for wafer interface 115 , user interface 120 , plasma processing unit 130 , controller 140 , and one or more power supplies 150 . Processing system 100 is supported by various facilities, which may include gas(s) 155, external power source 170, vacuum 160, and optionally other facilities. For clarity of illustration, internal plumbing and electrical wiring within processing system 100 are not shown.

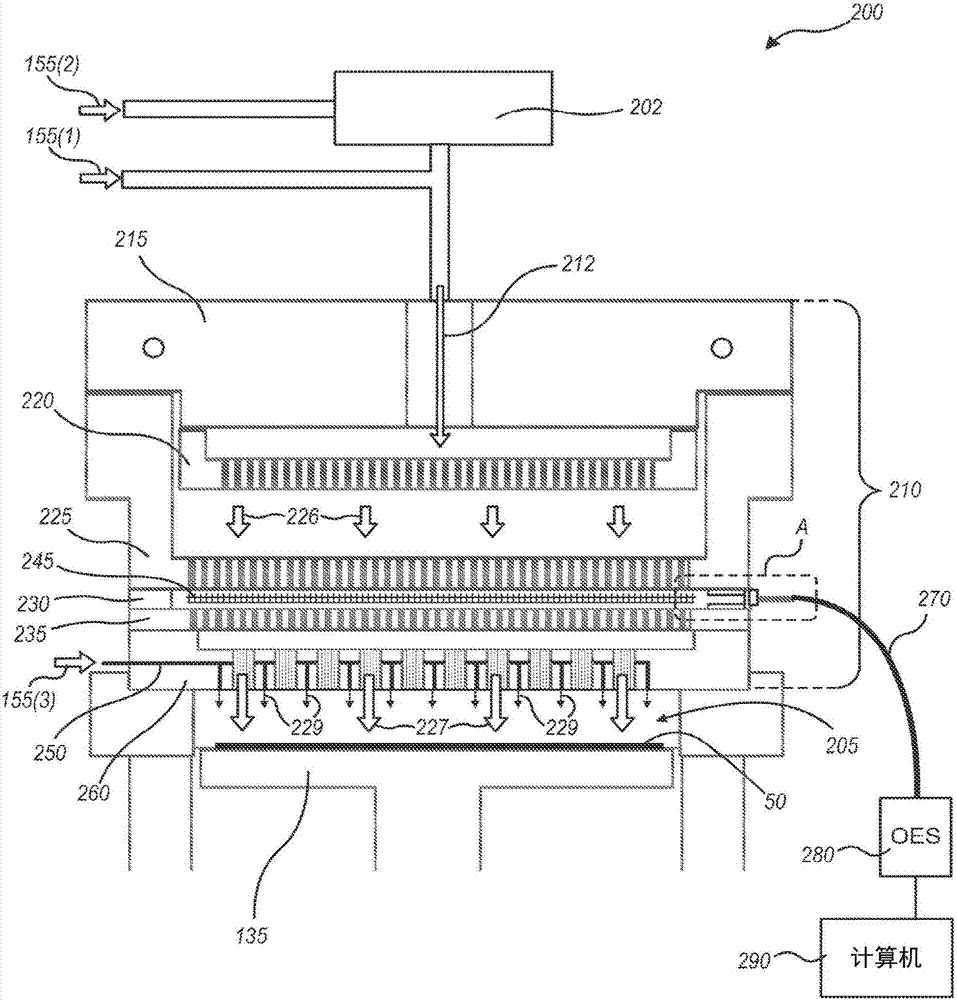

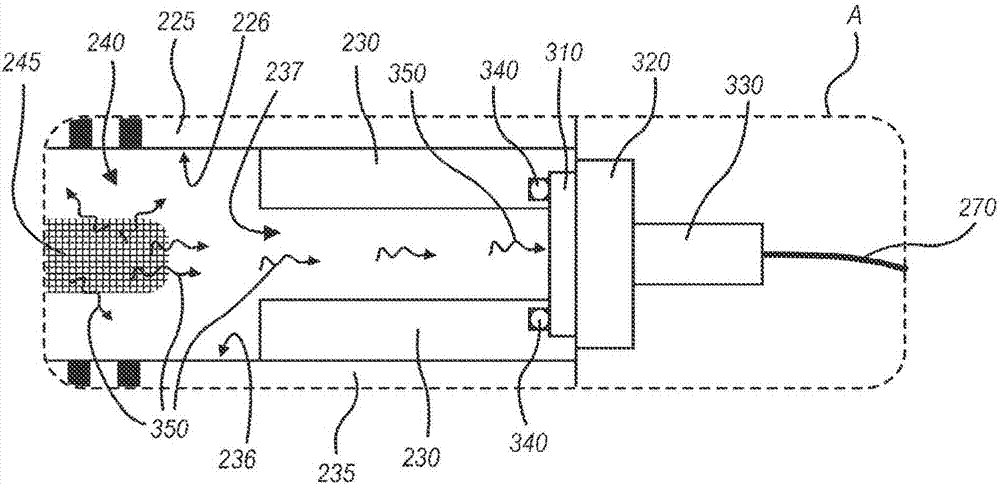

[0028] Processing system 100 is shown as a so-called indirect (or remote) plasma processing system that genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com