Exhaust gas aftertreatment device and exhaust gas aftertreatment method

A waste gas post-treatment and waste gas technology, which is applied in the direction of exhaust devices, silencers, gas chambers, etc., can solve the problems of corrosion, noise reducer weakening and stable matching, and infeasibility, so as to achieve effective noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention relates to an exhaust gas aftertreatment device for an internal combustion engine, in particular for a marine diesel internal combustion engine operated with heavy fuel oil.

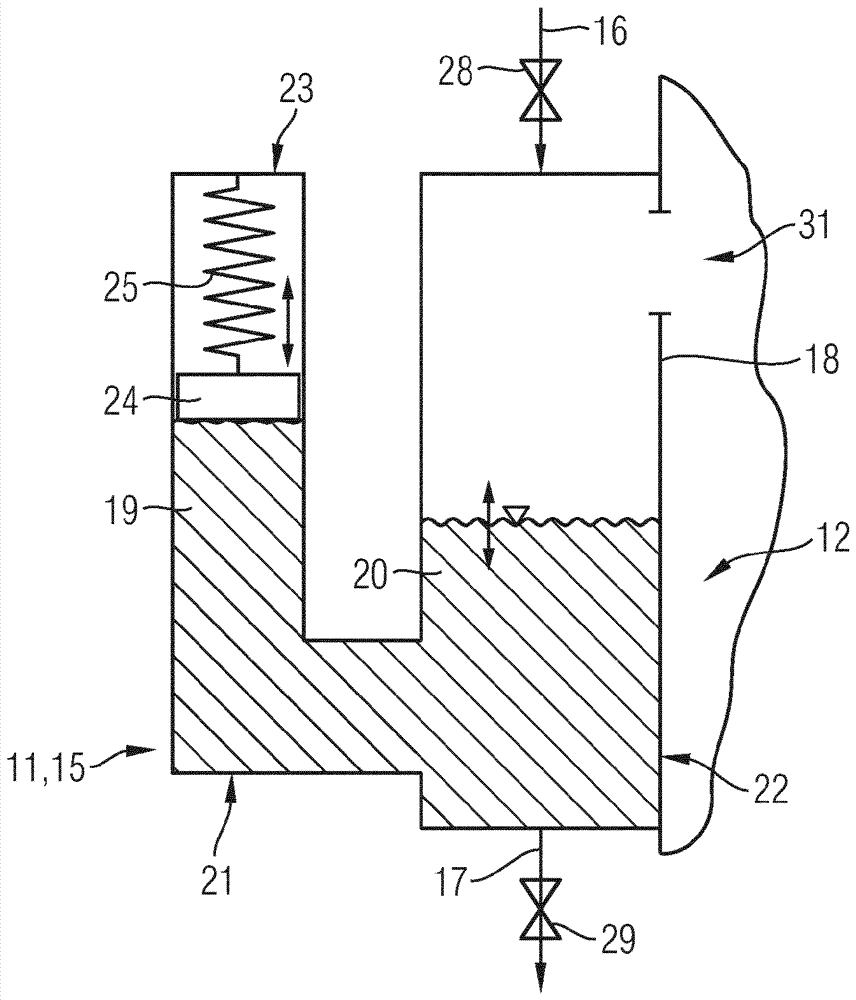

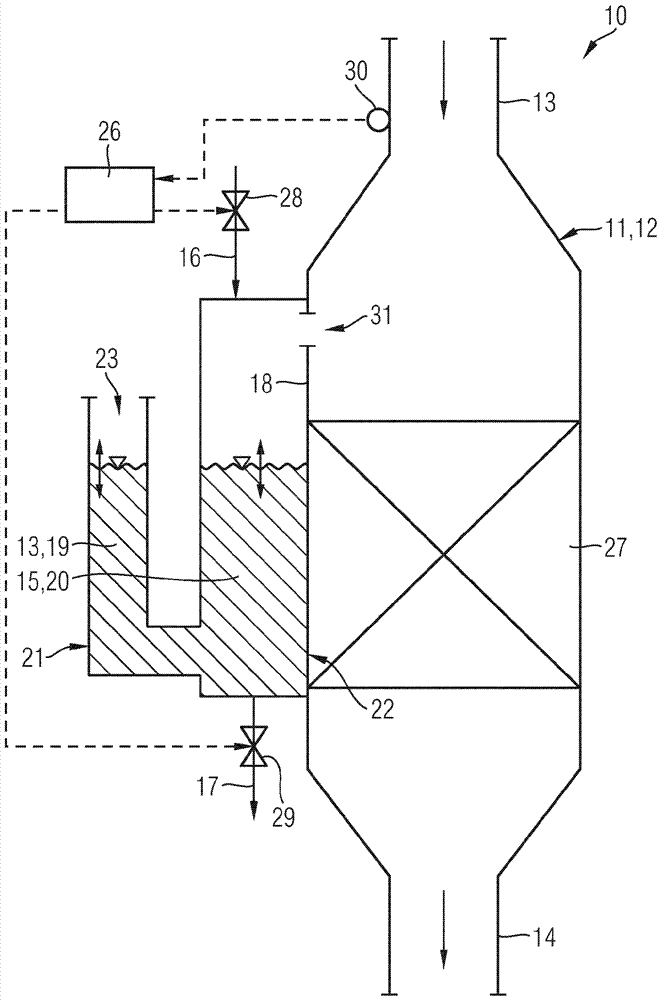

[0021] figure 1 A schematic view of a first exemplary embodiment of an exhaust gas aftertreatment device 10 according to the invention is shown for an internal combustion engine, in particular for a marine diesel internal combustion engine operated with heavy fuel oil.

[0022] The exhaust gas aftertreatment device 10 includes a housing 11 . The housing 11 delimits on the one hand an exhaust gas chamber 12 through which the exhaust gas flows continuously, into which the exhaust gas flows in via the inlet 13 and from which the exhaust gas flows out via the outlet; and on the other hand defines a noise reduction chamber 15 .

[0023] The noise reduction chamber 15 is connected to the exhaust gas chamber 12 .

[0024] A fluid, in particular a liquid or a flowable solid, in particular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com