Condensing tumble dryer including temperature sensor and method of operation thereof

A technology of tumble dryer and temperature sensor, which is applied in household dryers, textiles and papermaking, washing devices, etc., and can solve problems such as identifying operating status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

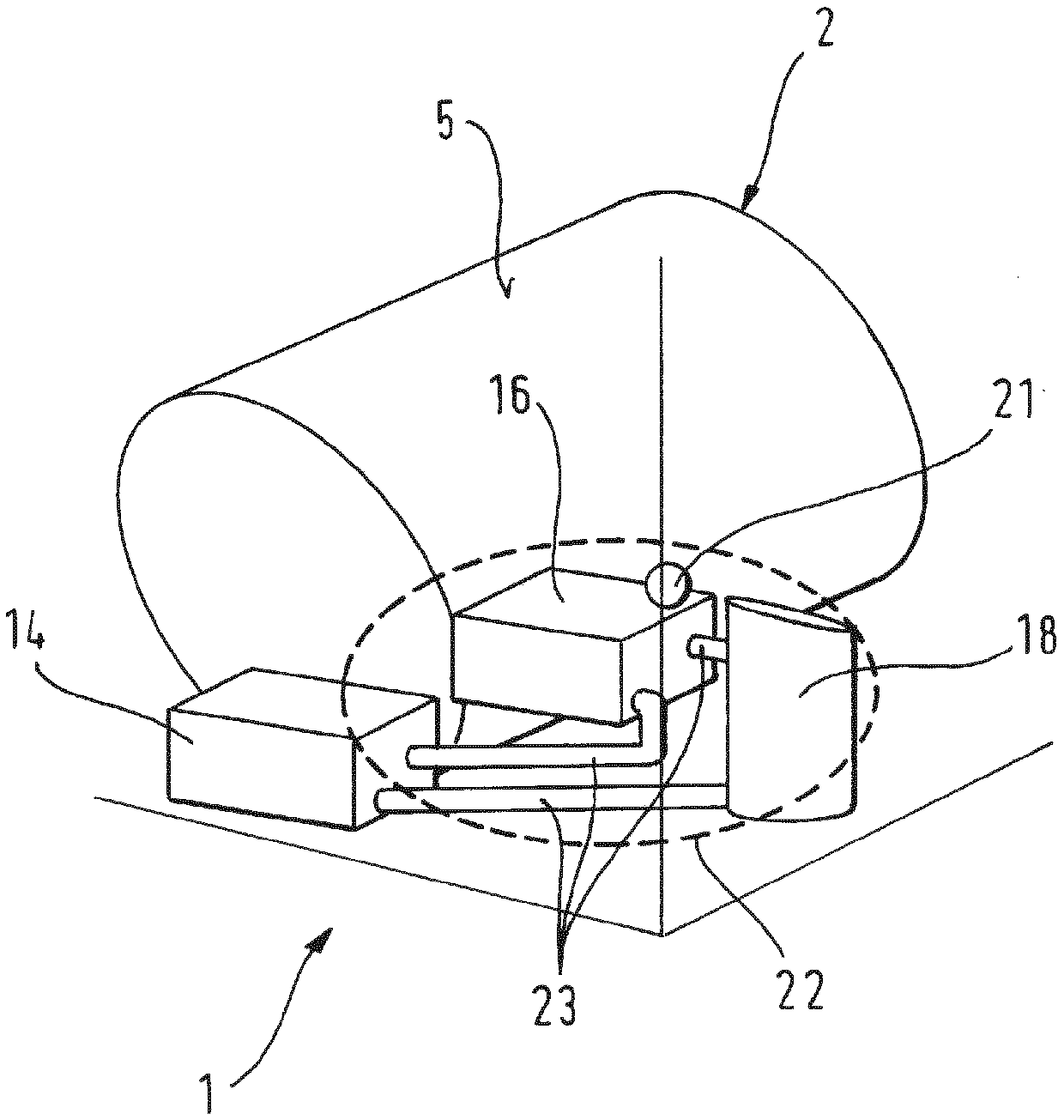

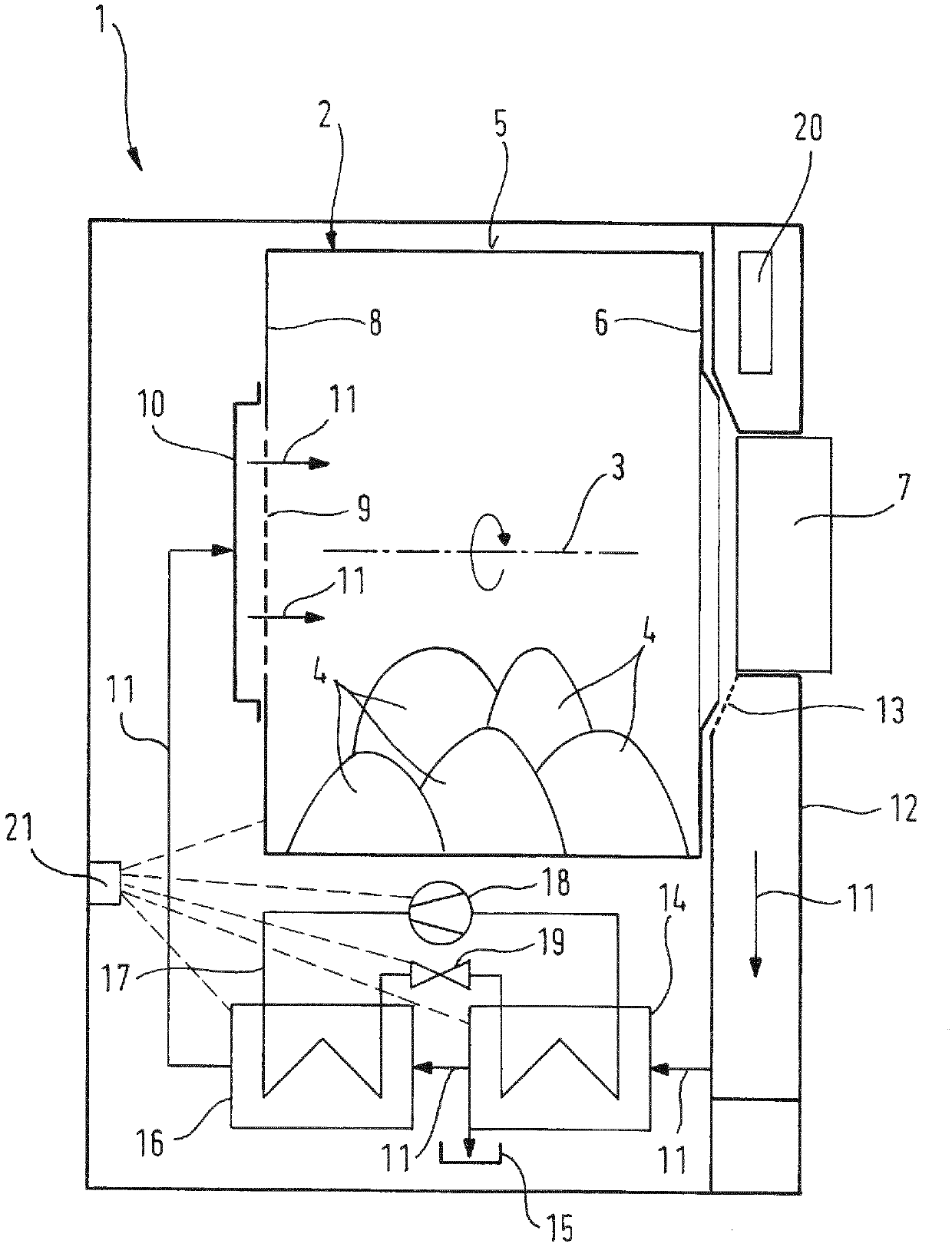

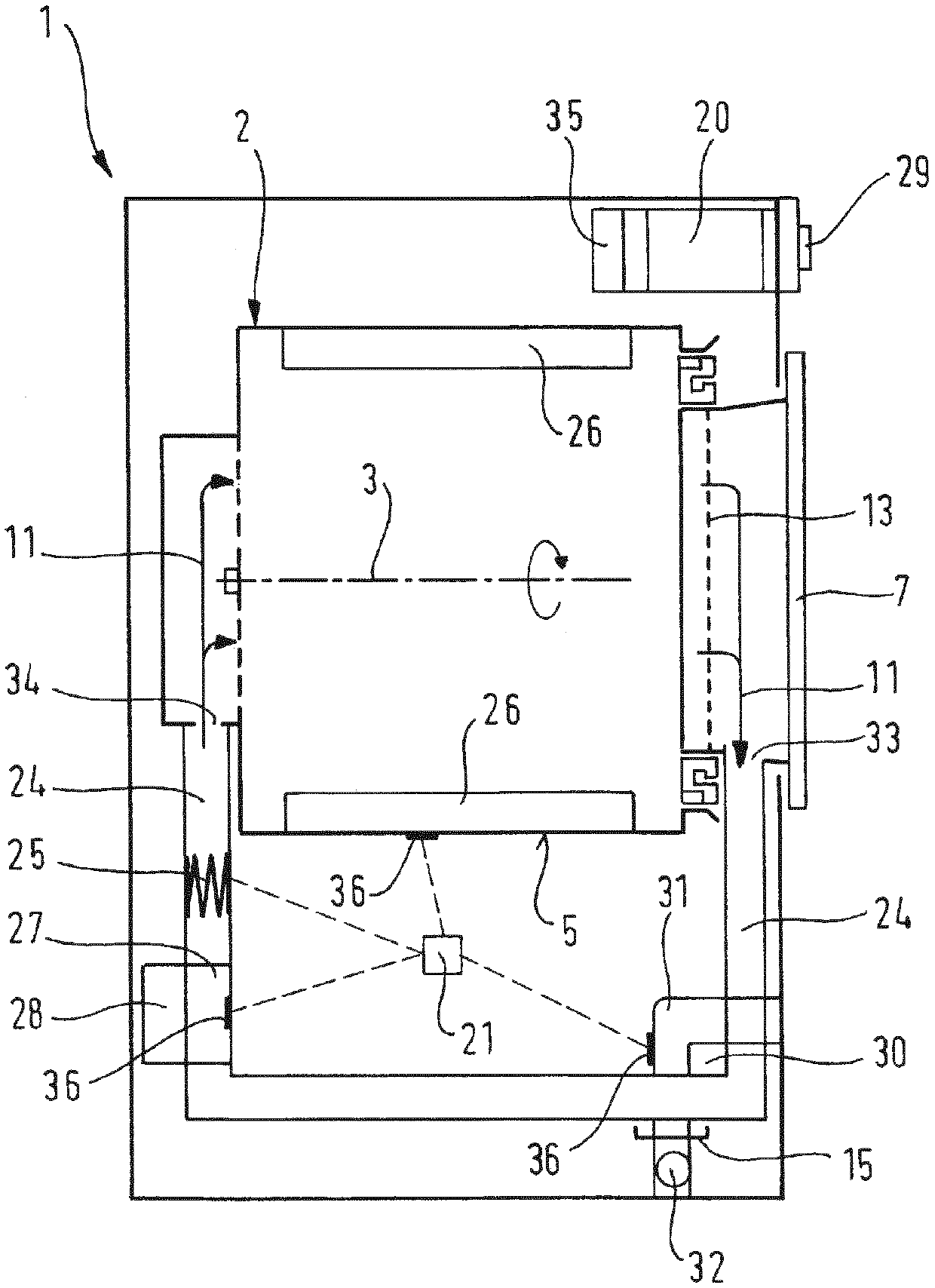

[0064] figure 1 A perspective view showing parts of the condensation tumble dryer, which is the heat pump tumble dryer 1 , according to the first embodiment, relates to the inventive essence.

[0065] figure 1 Shown is the cartridge 2 with the outer cartridge surface 5 and the components of the heat pump, namely the evaporator 14, the condenser 16, the compressor 18 and the pipes 23 connecting these components. The thermopile array 21 is arranged to be able to receive thermal radiation from the components of the heat pump as well as from the cartridge 2 . The viewing area or detection range of the path 22 of the heat radiation from the components of the tumble dryer to the infrared telescope 21 is shown here by an ellipse represented by dashed lines.

[0066] The infrared telescope 21 here includes a thermopile array 21 and an imaging optic positioned in front of the thermopile array 21 , which is not shown for clarity. The focal length of the optics can be several millim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com