Method for producing deuterium-depleted water, method for separating heavy water and light water, and method for producing deuterium-enriched water

A technology of manufacturing method and separation method, applied in the field of deuterium-depleted water, can solve the problems of high manufacturing cost and large economic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0061] The first embodiment is characterized in that activated carbon is prepared, and water vapor is supplied under a pressure at which heavy water and semi-heavy water are adsorbed but light water is hardly adsorbed.

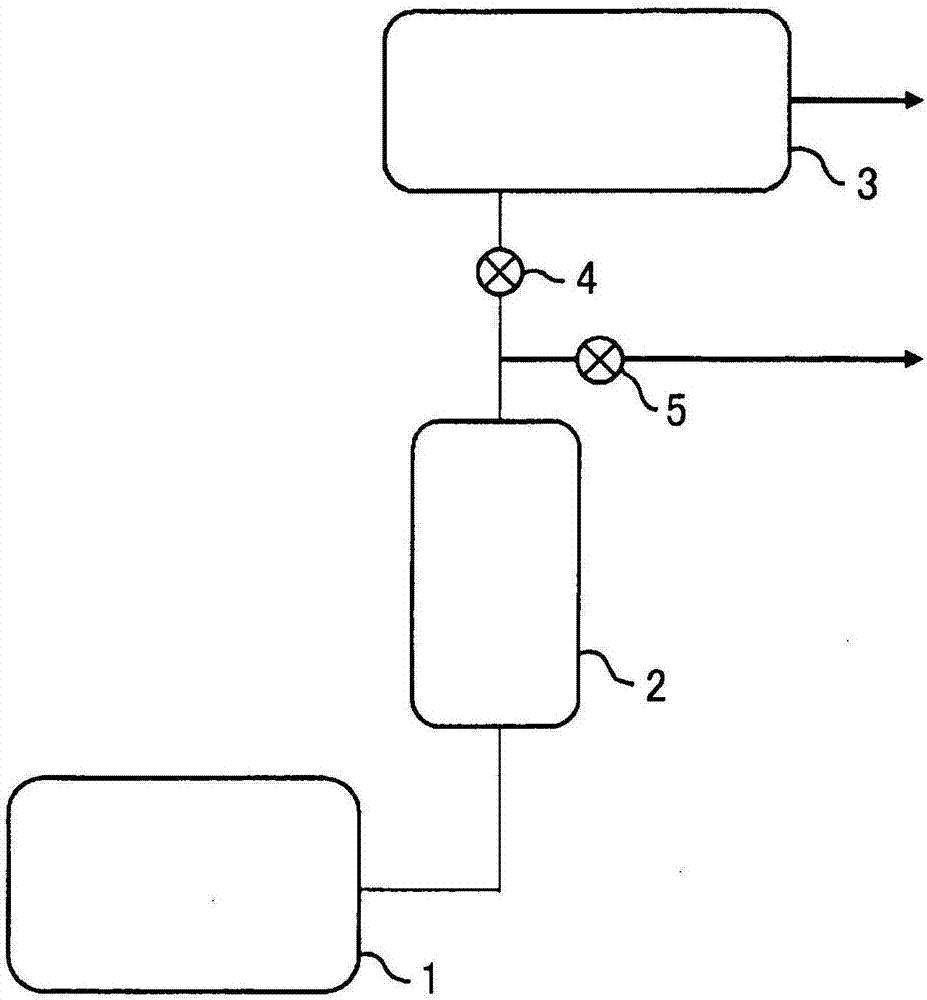

[0062] The separation device used in the first embodiment includes a gasification device 1 for supplying water as water vapor.

[0063] A pipe extending from the vaporizer 1 is connected to the adsorption tank 2 .

[0064] An adsorbent made of activated carbon is disposed inside the adsorption tank 2 .

[0065] On the downstream side of the adsorption tank 2, a liquefaction device 3 for converting water vapor into water is provided.

[0066] A stop valve 4 is installed in the middle of the piping connecting the adsorption tank 2 and the liquefaction device 3 .

[0067] The piping connecting the adsorption tank 2 and the liquefaction device 3 is branched in the middle, and water vapor can be discharged through the stop valve 5 .

[0068] exist figure 2 In ...

no. 2 approach

[0081] The second embodiment is characterized in that activated carbon having sufficiently adsorbed water vapor is prepared, and the ambient air pressure is maintained at a pressure at which light water desorbs and heavy water and semi-heavy water hardly desorb.

[0082] In the second embodiment, in the same manner as in the first embodiment, the figure 2 separation device.

[0083] In the second embodiment, first, water is vaporized in the gasification device 1, and supplied to the adsorption tank 2, for example, at 25° C. at a pressure of 20 Torr or more, so that the water vapor is sufficiently adsorbed on the adsorbent, and then, when When lowering to 13 Torr, a large amount of light water is released. Then, the shut-off valve 4 is opened, and the water vapor detached by the liquefaction device 3 is recovered into water for recovery, so that deuterium-depleted water with reduced deuterium concentration can be obtained.

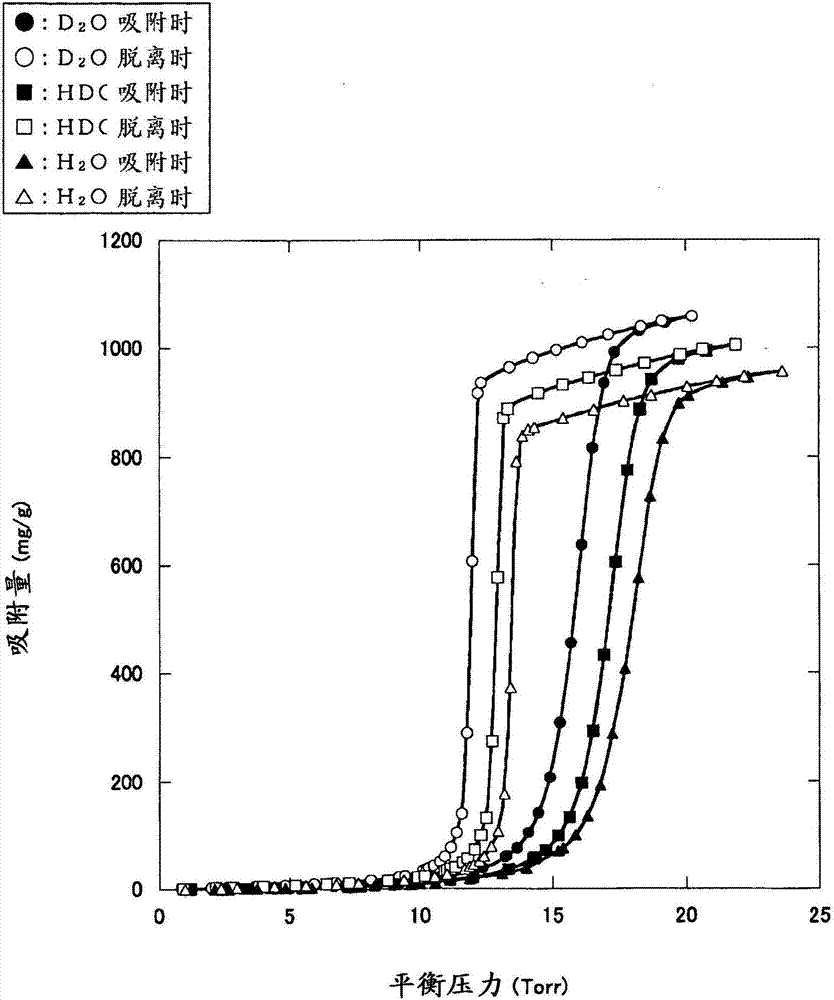

[0084] figure 1 The inclination of the adsorption...

no. 3 approach

[0087] The third embodiment is characterized in that the detachment process of the second embodiment is repeated.

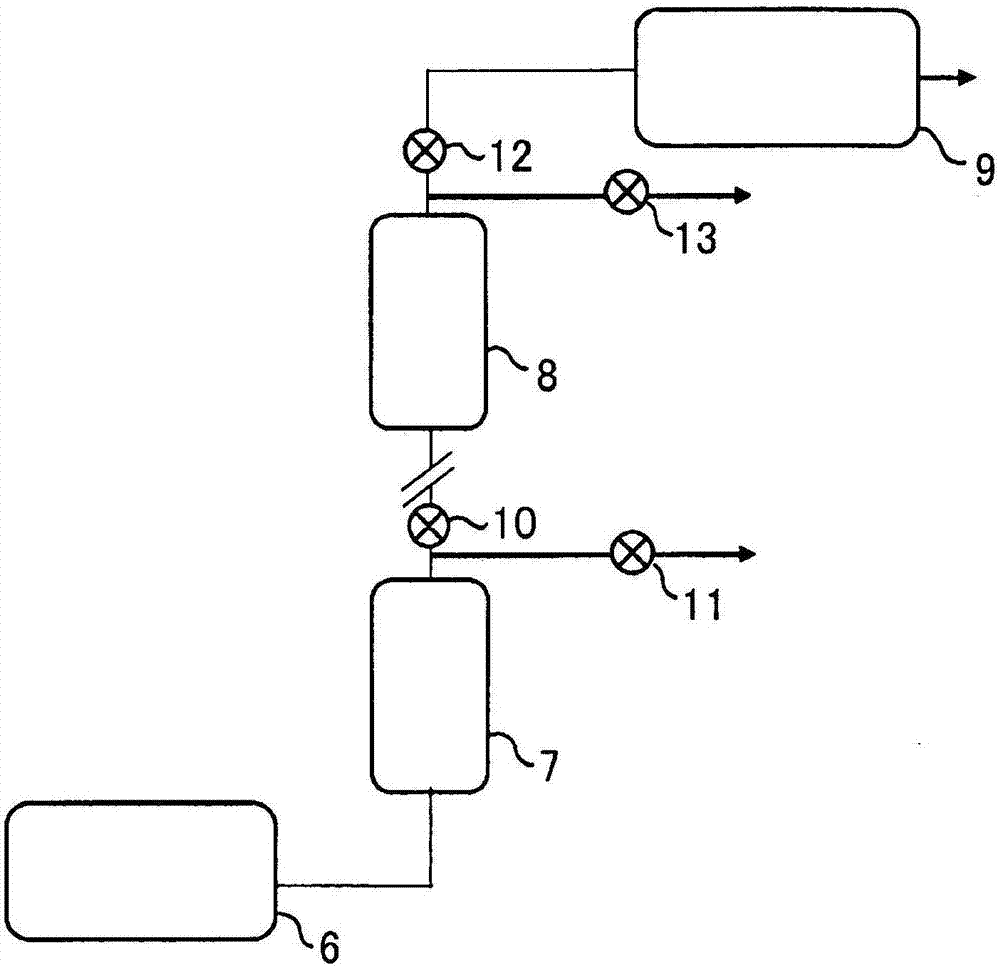

[0088] The separation device of the third embodiment has a gasification device 14 for supplying water as water vapor.

[0089] A pipe extending from the vaporizer 14 is connected to the adsorption tank 15 .

[0090] A stop valve 22 is provided in the middle of this piping.

[0091] An adsorbent made of activated carbon is arranged inside the adsorption tank 15 .

[0092] The adsorption tank 15 is connected to the first gas tank 16 by a predetermined pipe, and a pump 17 is disposed in the pipe. Water vapor can be reciprocated between the adsorption tank 15 and the first gas tank 16 by the pump 17 .

[0093] In addition, shutoff valves 23 and 24 are respectively provided on the pipes extending downstream from the adsorption tank 15 and the first gas tank 16 , and are merged into one downstream of the pipes to be connected to the second gas tank 18 .

[0094] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com