Heating hood apparatus having a novel type of arrangement of the heating device

A heating device and heating cover technology, applied in the field of heating cover, can solve problems such as damage, injury, inability to introduce heat into the substance to be heated, etc., and achieve the effect of precise execution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

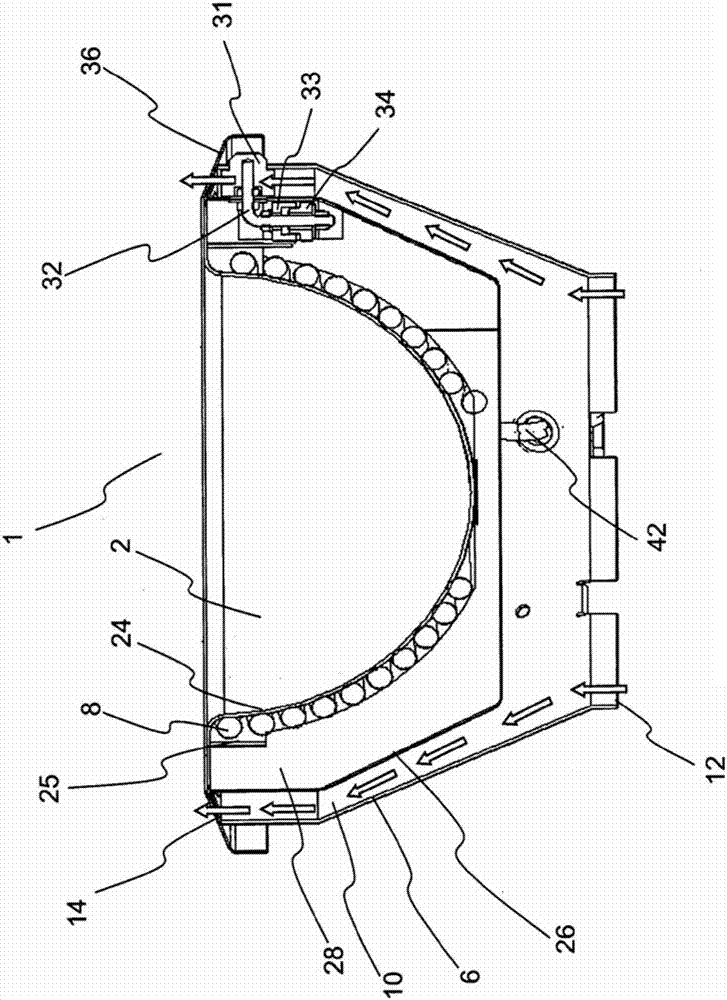

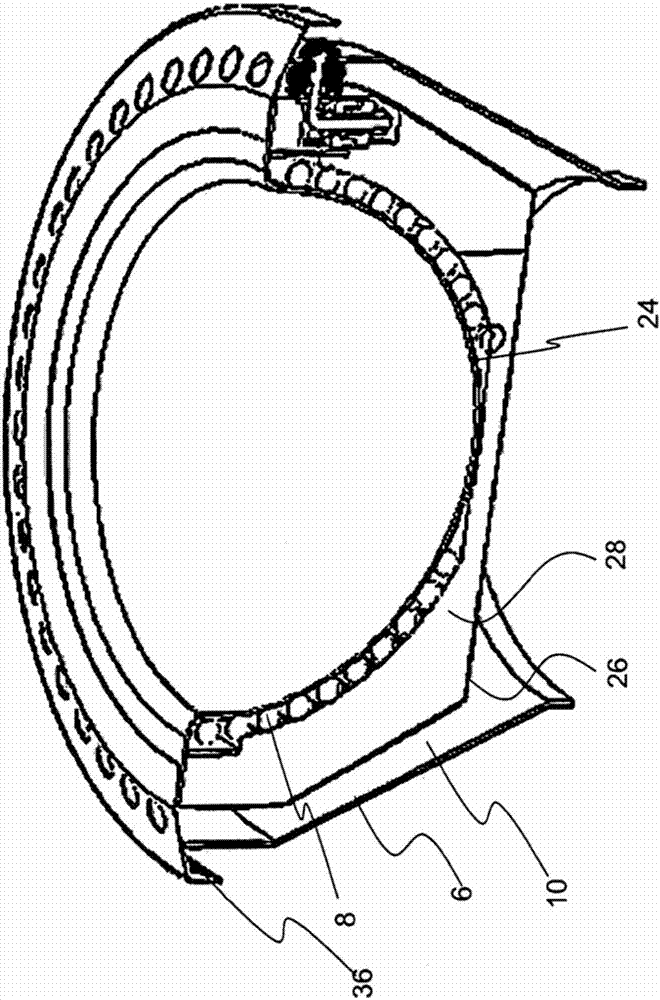

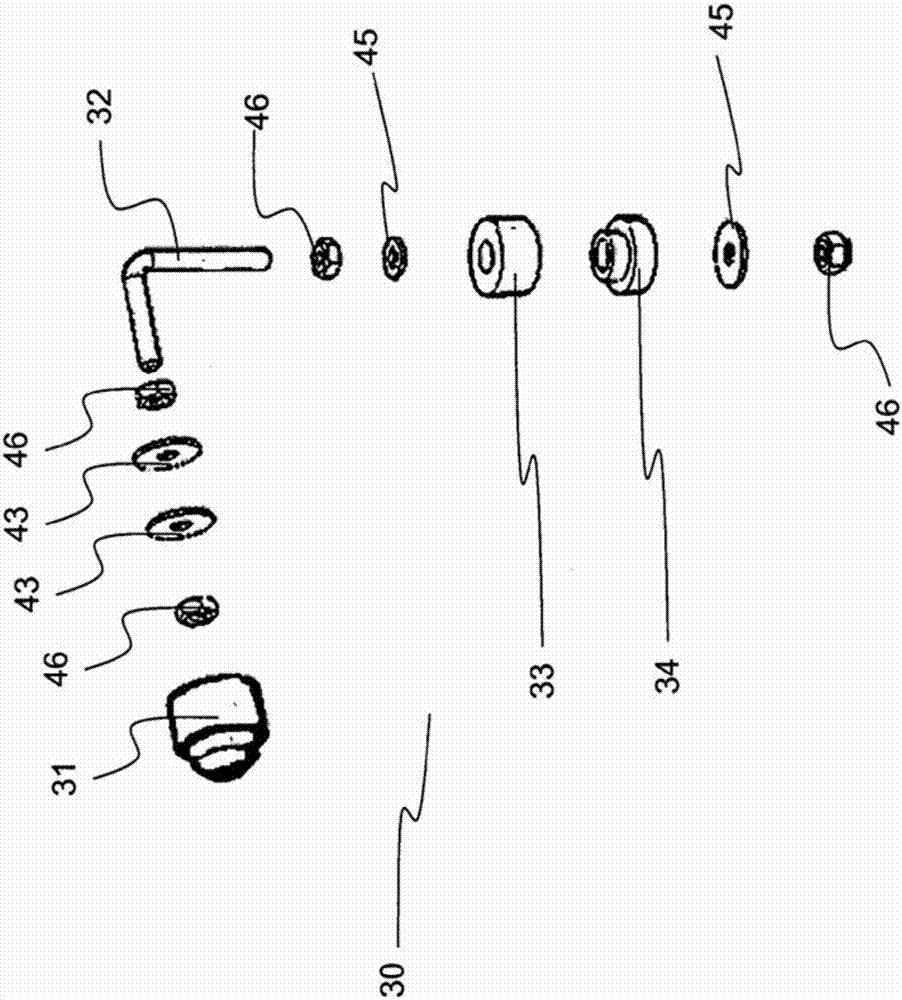

[0034] figure 1 An example of a heating hood arrangement 1 or a heating hood 1 according to the invention is shown. The heating mantle 1 has a heat transfer region 2 in which objects for temperature control can be placed or arranged. The heat transfer region 2 is delimited at least in sections by a cover layer 24 . The cover layer 24 is here preferably a thin layer element which preferably consists at least partially of glass fibers and / or other or alternative materials. Here, thin preferably means that the cross-sectional thickness is less than 10 mm. The cover layer 24 here preferably has the function of covering the heating device 8 . In addition or as an alternative, the cover layer 24 has a buffer between the heating mantle and the object 4 (see Figure 5 ), especially the function of the contact between the hollow vitreous bodies. The heating device 8 is preferably designed as a tubular mineral heating device. Preferably, the resistance element or heating resistor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com