Environmentally friendly copper thread cleaning device for motor winding cutting

A technology for motor windings and cleaning devices, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators, etc. It can solve the problems of stator winding disconnection, inconvenient cleaning, and a large number of wire ends, etc., and achieves strong practicability, simple structure, and easy cleaning. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

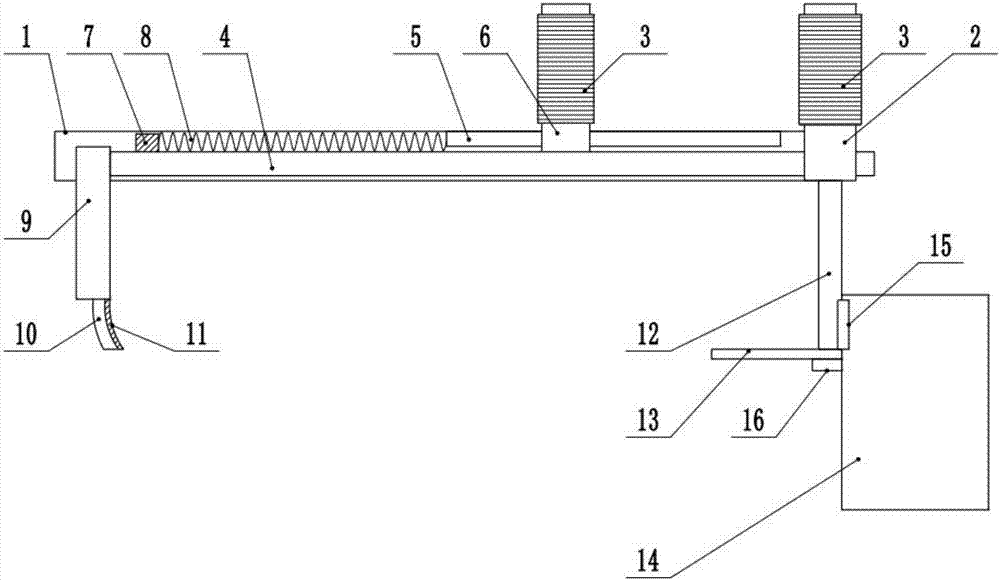

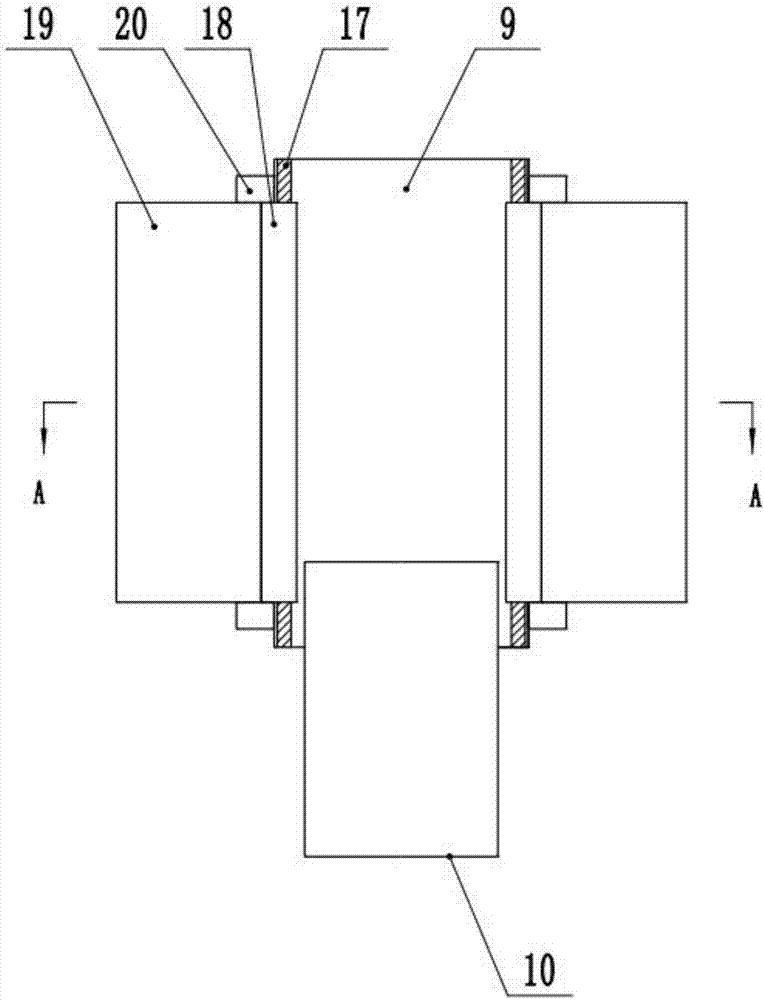

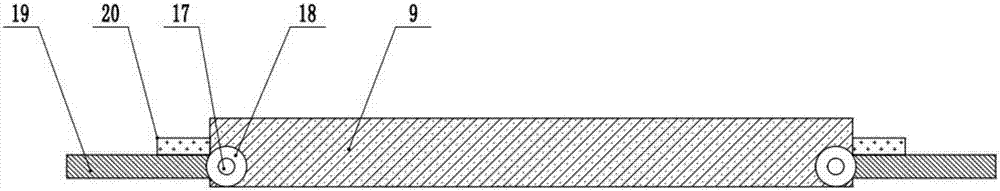

[0018] see figure 1 , an environment-friendly copper wire end cleaning device for motor winding cutting, comprising a device body, the device body is provided with a main bracket 1, the tail of the main bracket 1 is provided with a handle A2, and the handle A2 and the main bracket 1 are welded The main bracket 1 is a hollow structure, the upper end of the main bracket 1 is provided with a slot 5, the slot 5 communicates with the inside of the main bracket 1, and the inside of the main bracket 1 is provided with a sliding rod 4, The handle B6 is set on the slide bar 4, and the bottom of the handle B6 is fixedly connected with the slide bar 4 through the action of a set screw. The handle A2 and the handle B6 are provided with an anti-slip pad 3, and the anti-slip pad 3 is connected with the handle. A2 or the handle B6 is fixedly pasted and connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com