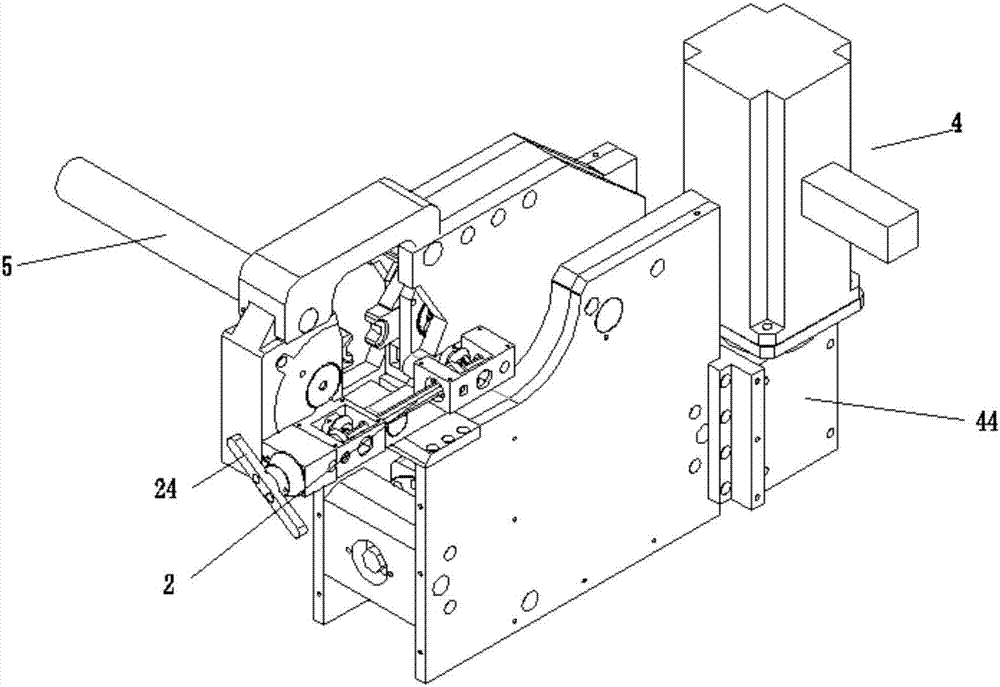

Terminal crimping machine

A terminal crimping machine and crimping die technology, applied in the direction of connection, vehicle connector, electrical components, etc., can solve the problems of reducing work efficiency, time-consuming, complicated operation, etc., to achieve automatic control, reduce energy consumption, reasonable The effect of configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

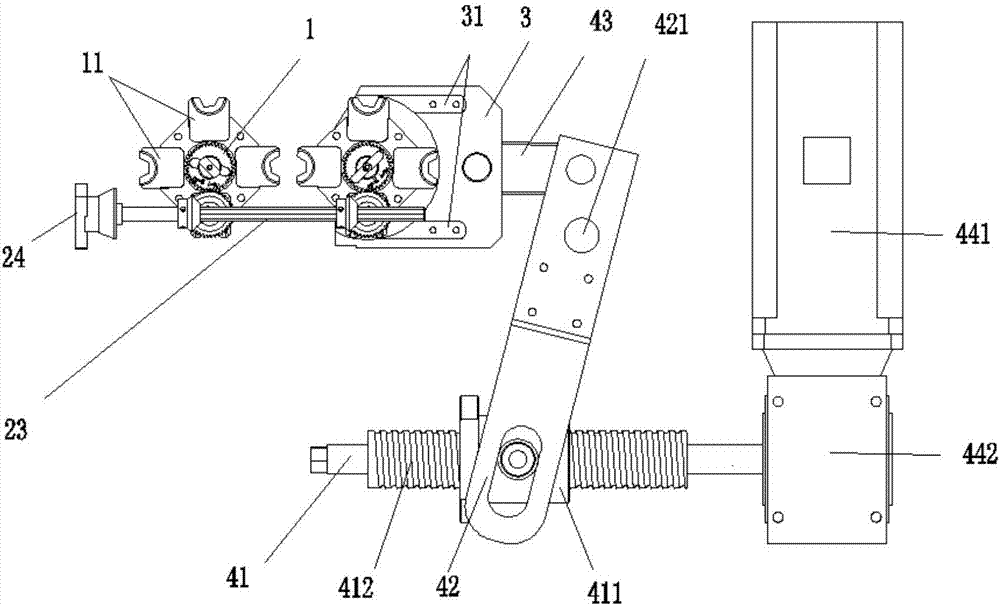

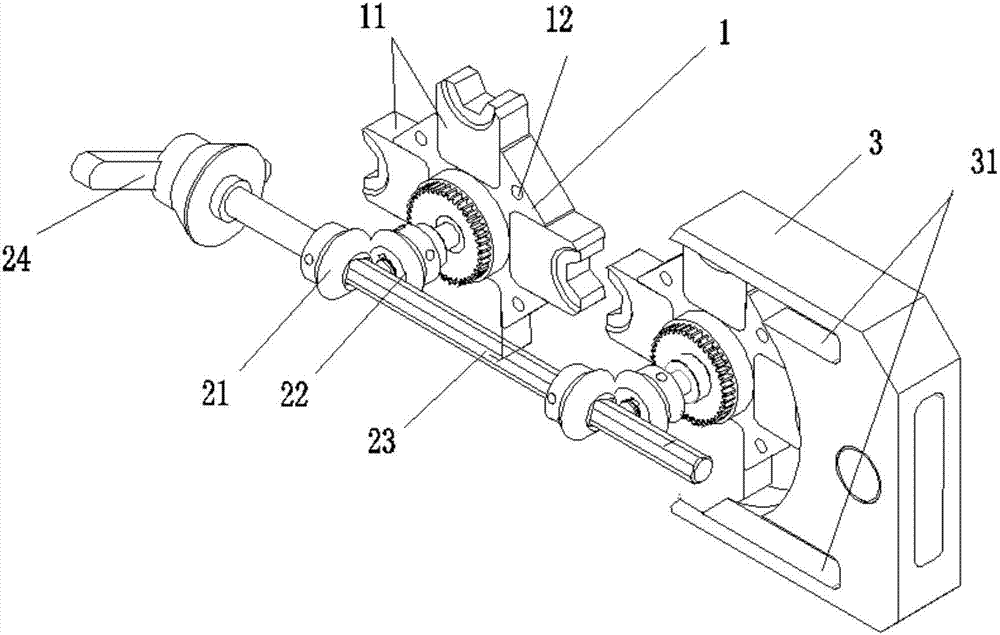

[0037] Such as image 3 As shown, the conversion assembly 2 includes a sector-shaped driving wheel 21 and a sector-shaped driven wheel 22. Two sets of sector-shaped driven wheels 22 are respectively arranged at the center of the main bodies of two groups of crimping modules 1, and two sets of sector-shaped driving wheels 21 are fixedly connected to the synchronous shaft 23 respectively. The rotation of two sets of fan-shaped driving wheels 21 is driven by rotating the synchronous shaft 23, and the fan-shaped driving wheels 21 drive the rotation of the fan-shaped driven wheels 22 which are engaged with it, and then respectively drive the center of the crimping module 1 fixedly connected with the fan-shaped driven wheels 22 shaft, with the rotation of the central shaft, the two groups of crimping modules 1 realize synchronous rotation, and then realize the synchronous replacement of crimping dies.

Embodiment 2

[0039] Such as Figure 4 As shown, the central axis of the crimping module 1 is connected with the first gear and the second gear meshed with it. The difference from Embodiment 1 is that the sector driven wheel 22 is connected with the central axis of the second gear, and the second gear drives the second gear. The rotation of the first gear can increase the positioning accuracy of the crimping die by increasing the number of teeth of the first gear, and the arrangement of multi-stage gears has higher working reliability, longer service life and stable transmission ratio.

[0040] figure 2 , image 3 and Figure 4 Among them, the reference numeral 11 represents crimping dies of different specifications set according to requirements.

[0041]When working, put the cable 5 to be processed into the processing station, provide power to the crimping module 1 through the power assembly 4, and perform the crimping operation. When the crimping size or crimping shape of the cable 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com