High precision six-degree-of-freedom optical component posture adjustment device

A technology for optical components and pose adjustment, applied in optical components, optics, installation, etc., can solve the problems of low lateral stiffness and high quality, and achieve the effects of low friction, large working space, and reduced gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

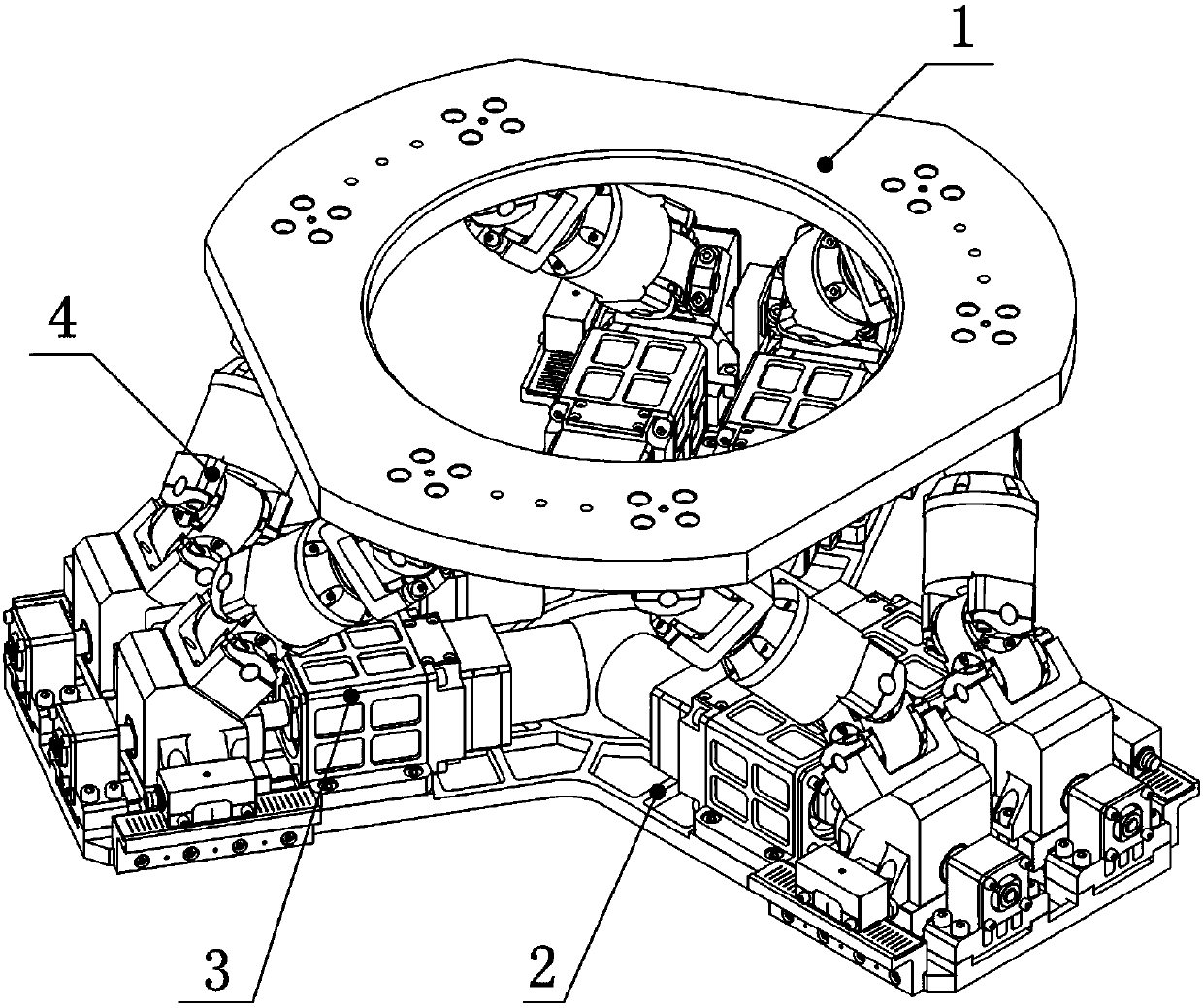

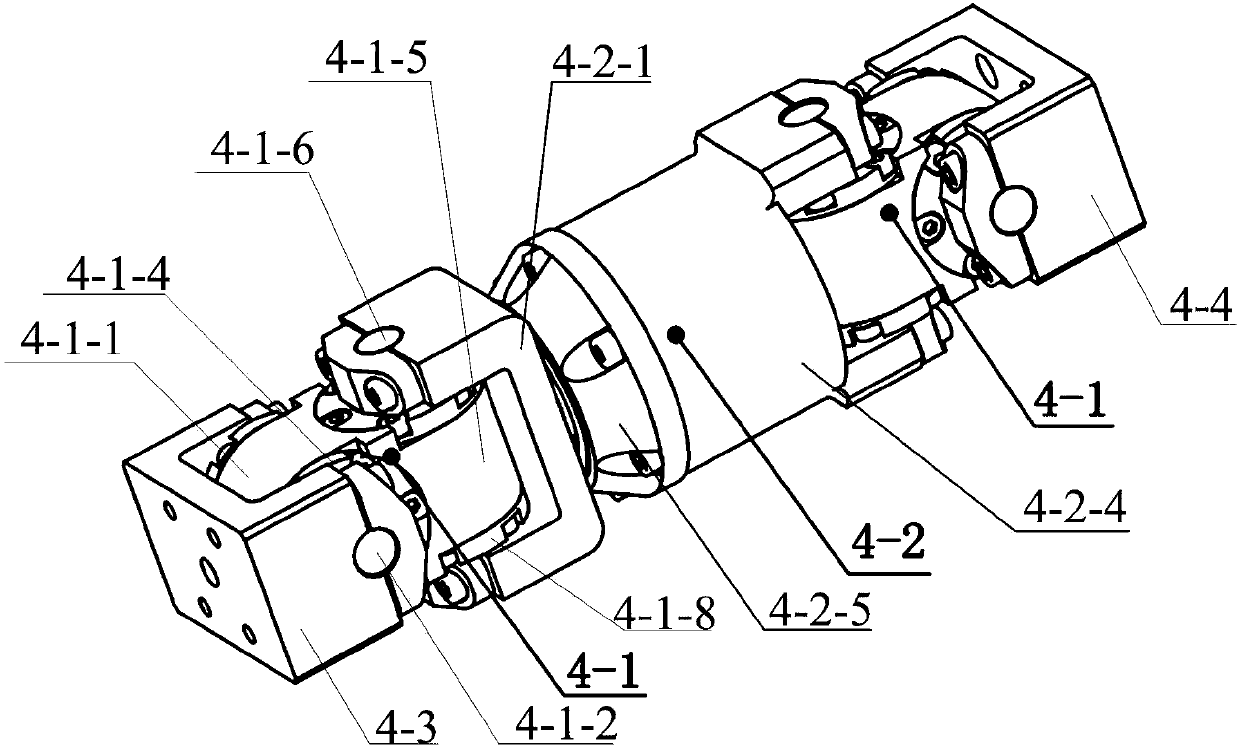

[0035] like figure 1 As shown, a high-precision six-degree-of-freedom optical assembly pose adjustment device of the present invention mainly includes a moving platform 1 , a fixed platform 2 , six linear actuators 3 and six rotating support hinges 4 . The moving platform 1 is the motion output end of the present invention, which is used to connect with the optical components in the large-scale space optical load, and realize the six-degree-of-freedom precision adjustment movement of the optical components. The fixed platform 2 is the connection end of the present invention and the large space optical load, and the fixed platform 2 is fixedly connected with the large space optical load. like figure 2 As shown, the fixed platform 2 forms a Y-shaped structure as a whole, and the three sides of the Y-shaped structure are all mounting surfaces, and the include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com