Opening type circular-pipe crawling detection device

A detection device, an open technology, applied in measuring devices, pipeline systems, material analysis using sound waves/ultrasonic waves/infrasonic waves, etc., can solve the problems of large engineering volume, less maintenance, installation environment, and low accuracy, and achieve simple control , to ensure comprehensiveness and reduce the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

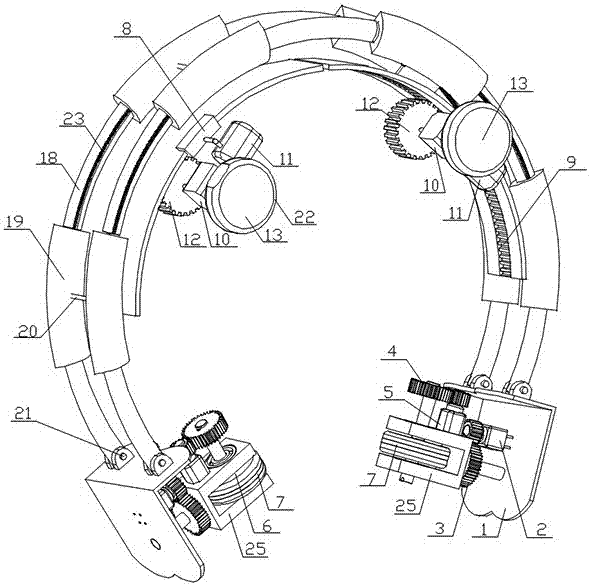

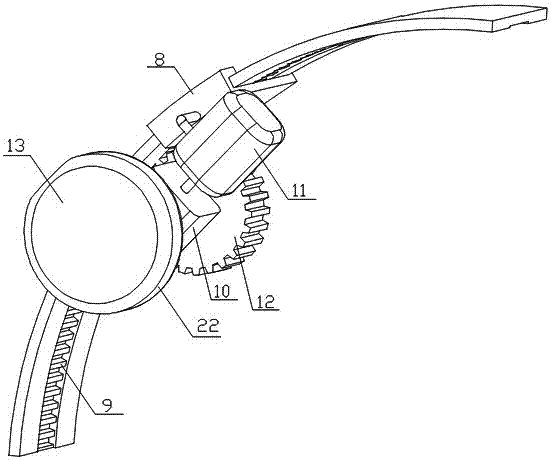

[0030] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, this open ring pipe crawling detection device includes a driving mechanism, a track clamping mechanism, and a detection mechanism. Fixed inside the track clamping mechanism. The open ring pipe crawling detection device has a span of 220° on the pipeline, which can ensure that the detection device runs smoothly and safely on the pipeline to complete the detection process. When the present invention is installed on the pipeline, the detector can overcome obstacles, pass different-diameter pipes, etc. through the deformation of the rail clamping mechanism.

[0031]In this embodiment, the rail clamping mechanism is a double-joint structure, which is composed of front and rear rings that are telescopically stretchable in the joint structure formed by con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com