Online detecting device for surface ash deposition degree of photovoltaic module and cleaning method for surface of photovoltaic module

A photovoltaic module and detection device technology, applied in the direction of photovoltaic power generation, photovoltaic modules, optical testing flaws/defects, etc., can solve the problems of performance change system prediction deviation, complex operation process, difficult unattended and remote early warning, etc., to achieve Effect of improving power generation income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with specific embodiments.

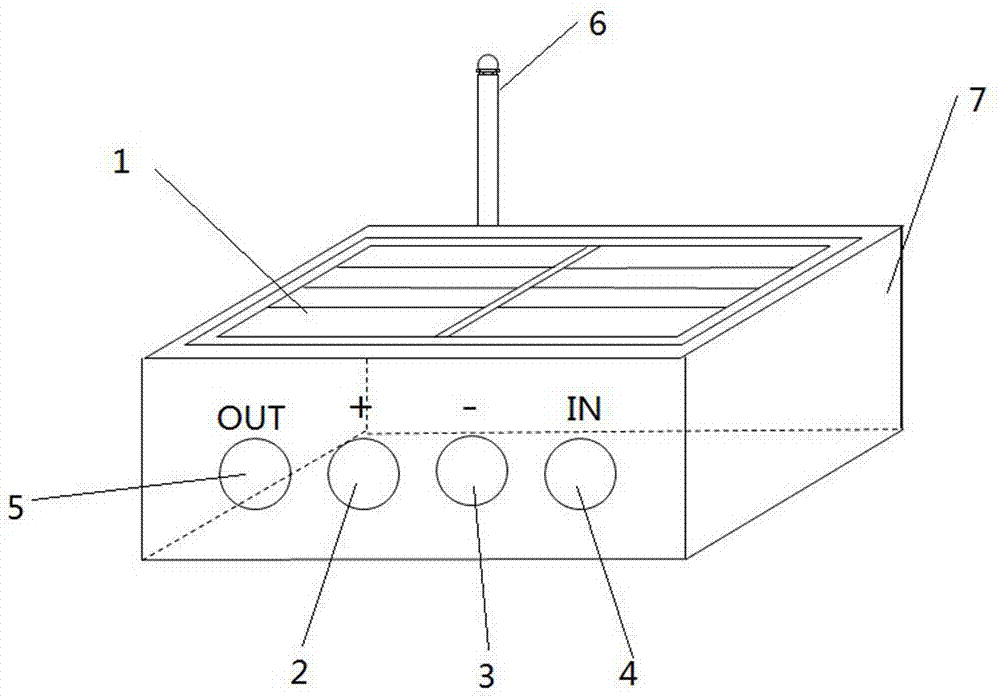

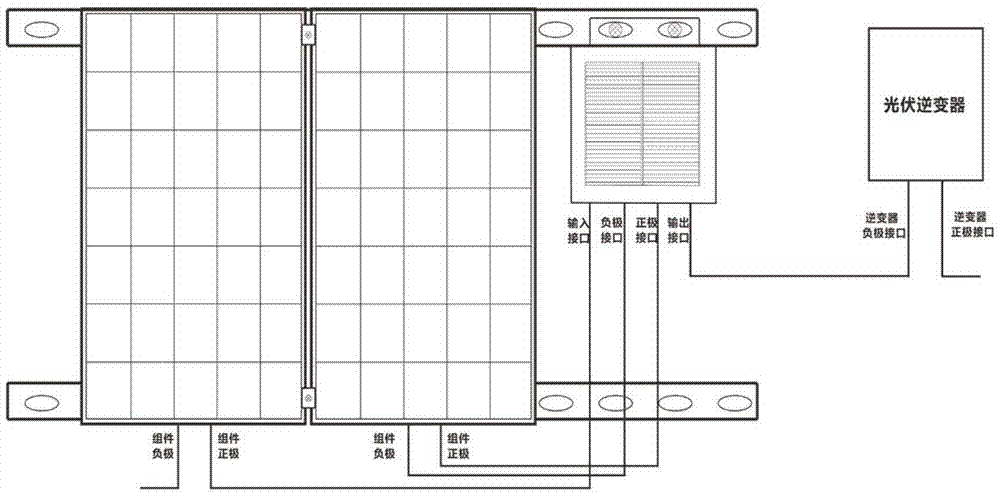

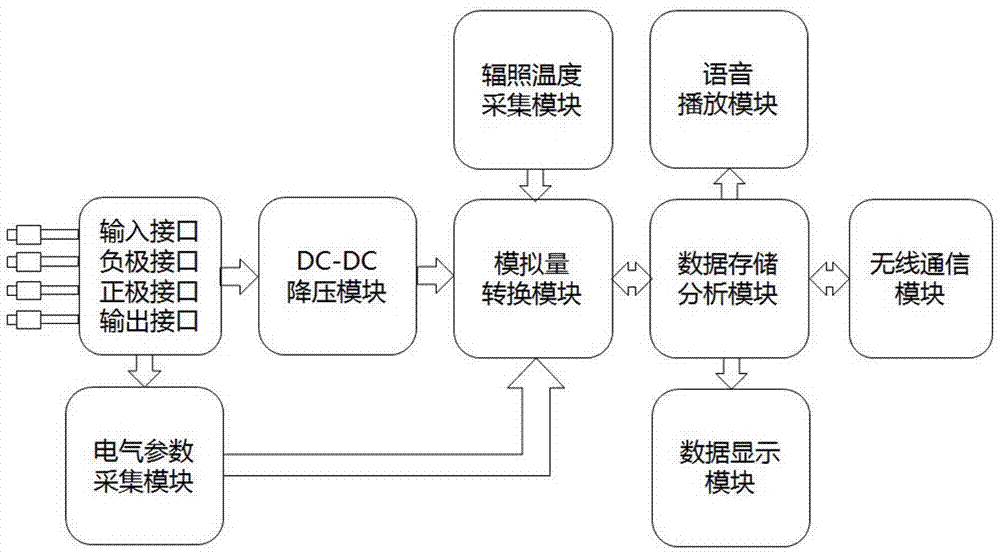

[0050] Such as Figure 1-3 As shown, an on-line detection device for the gray scale of the surface area of a photovoltaic module uses a crystalline silicon photovoltaic module 1 with a power of 0.5-2Wp as an irradiation sensor for real-time collection of light intensity;

[0051] The device of the present invention also includes a light intensity sensor installed on the top surface of the casing 7, the casing 7 is connected to the photovoltaic module, and the side of the casing 7 is provided with an input interface 4, an output interface 5, a positive interface 2 and a negative interface 3, and the input interface 4 is connected to the photovoltaic module. The positive pole of the last photovoltaic module under test is connected to the module positive pole, the output interface 5 is connected to the negative pole of the next photovoltaic module to be tested, the positive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com